Are Non-Conforming Golf Balls about to Go Mainstream?

Perhaps Nike Golf is betting on it! One of their patent applications recently published as US Pub. No. 20130324323 titled “Golf Ball Having A Cover Layer With Two Different Hardness Values.” Yes, a cover with 2 different hardness values!

The application explains:

Would you play such a ball?

David Dawsey – Keeping an Eye on Golf Ball Inventions

PS – Follow me on Twitter @GolfPatents to receive the latest golf patent updates

The application explains:

BACKGROUND

[0001] The present disclosure relates generally to a golf ball having a cover layer with at least two cover layer portions having different hardness values. In addition, the present disclosure relates generally to a method of making such a golf ball.

[0002] The game of golf is an increasingly popular sport at both the amateur and professional levels. A wide range of technologies related to the manufacture and design of golf balls are known in the art. Such technologies have resulted in golf balls with a variety of play characteristics. For example, different golf balls are manufactured and marketed to players having different golfing abilities, such as different swing speeds.

[0003] Similarly, a golfer may use different golf balls having different play characteristics depending on the golfer's preferences. For example, different dimple patterns may affect the aerodynamic properties of the golf ball during flight, or a difference in the hardness may affect the rate of backspin. With regard to hardness in particular, a golfer may choose to use a golf ball having a cover layer and/or a core that is harder or softer. A harder golf ball will generally achieve greater distances but less spin, and, therefore, will be better for drives but more difficult to control on shorter shots. On the other hand, a softer golf ball will generally experience more spin and, therefore, may be easier to control, but will lack distance.

[0004] Additionally, the spin rates of golf balls affect the overall control of the balls in accordance to the skill level of the players. Low spin rates provide improved driver and long-iron distance, but make golf balls difficult to stop on shorter shots, such as approach shots to greens. High spin rates allow more skilled players to maximize control of the golf ball, but may adversely affect driver and long-iron distance. To strike a balance between the spin rates and the playing characteristics of golf balls, additional layers, such as intermediate layers, outer core layers and inner cover layers are added to solid golf balls to improve the playing characteristics of the ball. The addition of multiple layers may add to the complexity of the manufacturing process as well as to the expense of manufacturing a golf ball.

[0005] While a variety of types of golf balls exist for different play characteristics, amateur golfers generally prefer to minimize the costs of purchasing new golf balls. However, a golfer may be required to purchase several sets of golf balls in order to achieve different play characteristics. For example, a golfer may purchase and use a set of hard golf balls for use specifically on longer courses, when the improved distance achieved by hard golf balls will be advantageous. In addition, a golfer may purchase and use a set of soft golf balls for use on shorter courses, or for use under conditions requiring increased control such as cold or wet weather. The need to purchase, store and carry several sets of golf balls in order to achieve a variety of play characteristics presents an inconvenience to the golfer, as well as increased costs.

DETAILED DESCRIPTION

[0041] The present disclosure generally relates to a golf ball having a first portion of a cover layer that is of one hardness value (for example, relatively hard) and a second portion of the cover layer that is of a second hardness value (for example, relatively soft). The first area is a contiguous hemisphere comprising approximately half of the golf ball cover layer. The second area is a second contiguous hemisphere comprising approximately a second half of the golf ball cover layer. As a result of such a cover layer, the golf ball may have one half of the golf ball that may be struck by a driver or wood to achieve greater distance and a second half of a golf ball that may be struck by a short iron or wedge to achieve greater control.

.

.

.

[0049] A golf ball having a cover layer with two cover layer portions with different hardness allows the golfer to choose the side of the golf ball the golfer desires to strike with a golf club. In some instances, a golfer may choose to hit the cover layer portion that has a greater hardness value when driving the golf ball off a tee or when using fairway woods or long-irons. Striking the harder cover layer portion with a wood or long-iron may provide the distance a golfer would expect when using such clubs. Further, striking the harder cover layer portion of the golf ball may also provide less backspin, which will assist with maintaining the driving distance.

[0050] In other instances, a golfer may choose to strike the softer cover layer portion with a short iron or wedge, or even a putter. Striking the softer cover layer portion may provide greater backspin. Further, striking the softer cover layer portion may also provide better control of the golf ball.

[0051] Embodiments of the disclosure include a golf ball having a cover layer comprising a first cover layer portion having a first hardness and a second cover layer portion having a second hardness. The first cover layer portion and second cover layer portion may be discernible to a golfer. In some embodiments, the first cover layer portion may be visibly discernible from the second cover layer portion of the golf ball cover layer. In other embodiments, the first cover layer portion may be tactilely discernible from the second cover layer portion. In further embodiments, the first cover layer portion may be both visibly and tactilely discernible from the second cover layer portion.

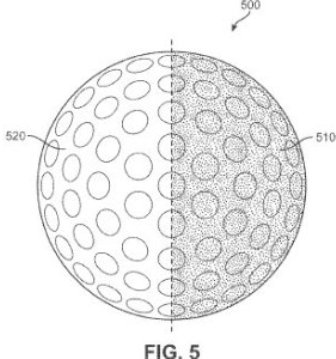

[0052] In FIG. 5, first cover layer portion 510 of finished golf ball 500 is visually distinguished from second cover layer portion 520. Each cover layer portion may have a different cover. For example, first cover layer portion 510 may have a grey color while second cover layer portion 520 may have a white color.

[0053] In other embodiments, the finished golf ball may have a stamp or mark noting a first cover layer portion and a second cover layer portion. As seen in FIG. 6, golf ball 600 has a first cover layer portion 610 and a second cover layer portion 620. Golf ball 600 may be a typical white color with a stamp or mark denoting each cover layer portion. The stamp or mark may be any suitable shape. In some embodiments, the stamps may be different shapes.

[0054] In FIG. 6, first cover layer portion 610 may be marked with rectangular stamp 630. Second cover layer portion 620 may be marked with circular stamp 640. In one embodiment, the circular stamp may mark the harder of the cover layer portions and the rectangular stamp may mark the softer of the cover layer portions. The shape or design of the stamp marking each cover layer portion can be any suitable design or shape to denote the cover layer portion of the ball being struck by a golf club.

[0055] Further, the color of the stamp can be any suitable color the manufacturer chooses. In some embodiments, the stamps may be the same color. In other embodiments, the stamps may be different colors.

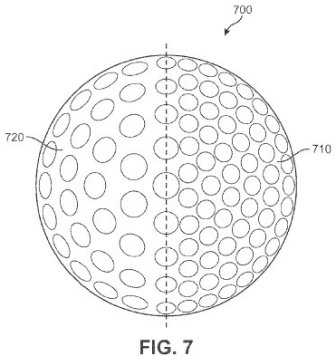

[0056] The cover layer portions may be further distinguished in both a visibly and a tactilely manner. Typically, golf ball cover layers comprising a plurality of dimples in any pattern. The plurality of dimples may generally be arranged on the cover layer in any pattern, as may be known in the art of golf balls. Various known dimple packing patterns are known in the art. Dimples may generally be of any shape, such as circular, triangular, or multi-sided shapes. Further, dimples may be of uniform shape and size, or the dimple pattern may be of two or more different types of dimples having (for example) different sizes or different shapes. In some embodiments, the cover layer may have two different dimple patterns denoting the two cover layer portions.

.

.

.[0057] FIG. 7 illustrates golf ball 700 having a cover layer with two different dimple patterns, each pattern comprising a plurality of dimples. First cover layer portion 710 may be distinguished from second cover layer are 720 through different dimple patterns. First cover layer portion 710 may have a dimple pattern comprising a plurality of circular dimples of a smaller size. In contrast, second cover layer are 720 may have a plurality of circular dimples of a larger size. The dimple pattern may be any suitable dimple pattern the manufacturer chooses.

[0058] The different dimple patterns may provide a visible method for the golfer to discern which cover layer portion of the finished golf ball the golfer is hitting with a golf club. The dimple pattern may be different enough that the golfer can readily discern which side of the ball the golfer is hitting. Further, the dimple pattern difference may also provide a tactile method for the golfer to discern which cover layer portion of the finished golf ball the golfer is hitting with a golf club. The golfer may be able to feel with their fingers the different dimple patterns to determine the cover layer portion the golfer would like to hit. Again, the dimple pattern difference may be different enough for the golfer to readily discern the different cover layer portions visually, tactilely, or both.

[0059] In addition to each method of marking the different cover layer portions, any combination of the above marking methods may be used. For example, in some embodiments, the cover layer portions may have different stamps and different dimple patterns denoting each cover layer portion. In other embodiments, the cover layer may have two different dimple patterns and the different colors marking each cover layer portion. In further embodiments, the cover layer may have different colors and different stamps marking each cover layer portion. In still other embodiments, the cover layer may have all three methods, different stamps, different colors and different dimple patterns, for marking the cover layer portions.

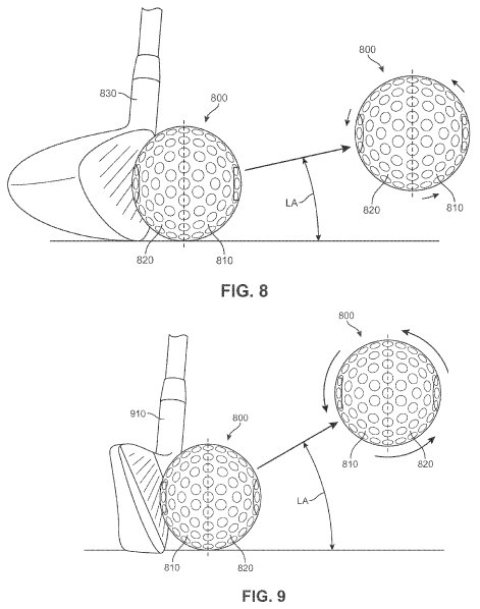

[0060] As stated above, a golfer may choose one face of the golf ball over the other when hitting the golf ball with a golf club. For example, as illustrated in FIG. 8, a golfer may choose to strike the harder face of the golf ball. In some embodiments, as illustrated in FIG. 6, the circular mark on the golf ball indicates the harder of the cover layer portions. FIG. 8 shows a driver or wood striking the golf ball of FIG. 6.

[0061] In FIG. 8, golf club 830 strikes golf ball 800 on cover layer portion 820. When struck with this type of club on the harder cover layer portion, the launch angle of the ball is lower, when compared to being struck with a short iron or wedge. In addition, striking golf ball 800 with a wood or long-iron on harder cover layer portion 820 produces less spin on the golf ball, as indicated by the short arrows rotating about golf ball 800.

[0062] A finished golf ball is typically tested to determine a wide variety of play characteristics. For example, a golf ball may be struck with one or more golf clubs in a test facility. During testing, characteristics, such as initial velocity, launch angle and the back pin of the golf ball are measured.

[0063] In some instances, a finished golf balls may be hit in an indoor range with a driver swung at a particular head speed, for example, between about 125 mile per hour and about 140 miles per hour (mph). When struck with a driver at those speeds, a typical golf ball exhibits a backspin of between about 2400 and about 3200 revolutions per minute (RPMs). In addition to a lower backspin, a finished golf ball may have an initial velocity of about 136 to about 142 mph. The launch angle of the golf ball may be between about 8.degree. and about 12.degree..

[0064] The golf ball of the present disclosure may exhibit similar characteristics when struck with a wood or long-iron on the harder face of the cover layer. The golf ball may have an initial velocity between about 136 to about 142 mph, a launch angle between about 8.degree. and about 12.degree., and a backspin rate of between about 2400 and about 3200 rpms.

[0065] In contrast to FIG. 8, FIG. 9 illustrates short iron or wedge 910 striking golf ball 800 on softer cover layer portion 810. In comparison to being struck with a wood on larder cover layer portion 820, when struck with a short iron or wedge on the softer cover layer portion, golf ball 800 has a higher launch angle and is subject to greater backspin.

Would you play such a ball?

David Dawsey – Keeping an Eye on Golf Ball Inventions

PS – Follow me on Twitter @GolfPatents to receive the latest golf patent updates

Comments