How Long Before Every Pro Golfer Has Their Own Golf Ball Dimple Profile?

I wonder if it is just a matter of time before each pro golfer has their own custom dimple pattern and/or profile; similar to how they all have their preferred wedge grinds. Why am I thinking about such nonsense? Simple, because a Nike patent application that published this week leads me to believe that the concept may not be outside the realm of possibility.

The patent application published as US Pub. No. 20130221577 titled “System And Method For Making Golf Balls,” which describes the invention as:

The application explains:

David Dawsey – Keeping an Eye on Golf Ball Inventions

PS – Follow me on Twitter (@GolfPatents) to receive the latest golf patent updates

The patent application published as US Pub. No. 20130221577 titled “System And Method For Making Golf Balls,” which describes the invention as:

A system and method for making golf balls is disclosed. The system may include laser cutting dimples into a golf ball cover layer. Laser cutting may also be used to add texture to the surface of a golf ball. Laser cutting dimples may provide flexibility in quickly creating different shapes, sizes, and patterns of dimples. Thus, during golf ball testing, a certain pattern of dimples may be made, tested, and then quickly adjusted. For example, the dimples may be adjusted by cutting away more cover material to make the dimples larger, deeper, and/or in a different shape. After further testing, the golf ball dimples may be adjusted again multiple times.

The application explains:

BACKGROUNDNot exactly the artistic personal touch of grinding a player's wedge, but pretty darn cool. I wonder how long each ball would take, not to mention the final cost of a ball with laser cut dimples.

[0001] The present invention relates generally to a system and method for making a golf ball. In particular, the system and method relates to making golf ball dimples.

[0002] The game of golf is an increasingly popular sport at both amateur and professional levels. A wide range of technologies related to the manufacture and design of golf balls are known in the art. For instance, a method of manufacturing golf balls involves forming dimples on the balls by placing the balls into hemispherical molds having protrusions corresponding to dimples, injecting cover material inside the molds, and applying heat and pressure to the ball. This method applies a coating and forms dimples on the surface of the golf ball. While this method works well, it requires a mold to be made. Accordingly, making prototypes of golf balls with different dimple patterns can be time consuming. It would be advantageous to be able to make dimples on the surface of a golf ball without using a mold. It would also be advantageous to be able to adjust existing dimples on golf balls.

SUMMARY

[0003] A system and method for making golf balls is disclosed. The system may include laser cutting dimples into a golf ball cover layer. Laser cutting may also be used to add texture to the surface of a golf ball. Laser cutting dimples may provide flexibility in quickly creating different shapes, sizes, and patterns of dimples. Thus, during golf ball testing, a certain pattern of dimples may be made, tested, and then quickly adjusted. For example, the dimples may be adjusted by cutting away more cover material to make the dimples larger, deeper, and/or in a different shape. After further testing, the golf ball dimples may be adjusted again multiple times.

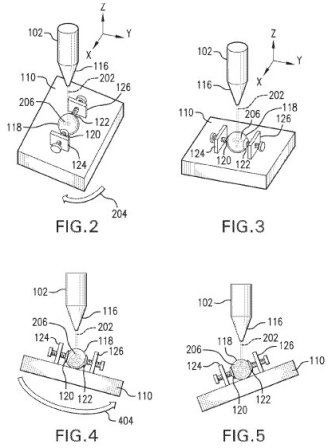

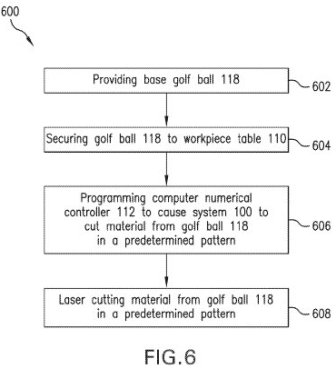

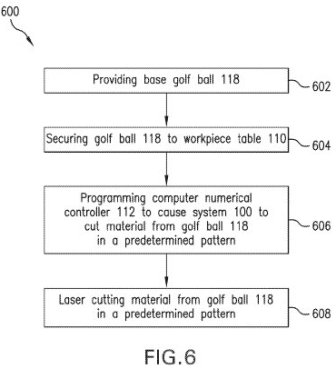

[0004] In one aspect the disclosure provides a method of making a multi-layered article. The method may include providing a base article and laser cutting material from an outer layer of the base article in a predetermined pattern. Laser cutting material from the outer layer may include not cutting material from any other layers of the article. The base article may include a base golf ball. The predetermined pattern may include one of a dimple pattern and a textured pattern. Laser cutting material from the surface of the base multi-layered article may include securing the multi-layered article to a workpiece holder. Laser cutting material from the outer layer of the base golf ball may include programming a computer numerical controller to cause a laser cutting system to remove material from the outer layer of the golf ball. Laser cutting material from the outer layer of the base golf ball may include programming a computer numerical controller to move the base golf ball relative to a laser head as the laser head cuts material from the outer layer of the base golf ball. Laser cutting material from the outer layer of the base golf ball may include programming a computer numerical controller to move the laser head relative to the base golf ball as the laser head cuts material from the outer layer of the base golf ball. Laser cutting material from the outer layer of the base golf ball may include moving the base golf ball relative to a laser head as the laser head cuts material from the outer surface of the base golf ball. Laser cutting material from the outer surface of the base golf ball may include moving a laser head relative to the base golf ball as the laser head cuts material from the outer surface of the base golf ball.

[0005] In another aspect, the disclosure provides a method of making a golf ball. The method may include forming a golf ball core, forming a golf ball cover surrounding the golf ball core, and laser cutting material from the golf ball cover in a predetermined pattern. Forming a golf ball cover surrounding the golf ball core may include placing the golf ball core between at least two mold chambers, pressing the at least two mold chambers together, and injecting a golf ball cover material into the mold chambers. The predetermined pattern may include a dimple pattern. The predetermined pattern may include a textured pattern. Laser cutting material from the surface of the base golf ball may include programming a computer numerical controller to move the base golf ball relative to a laser head as the laser head cuts material from the surface of the base golf ball.

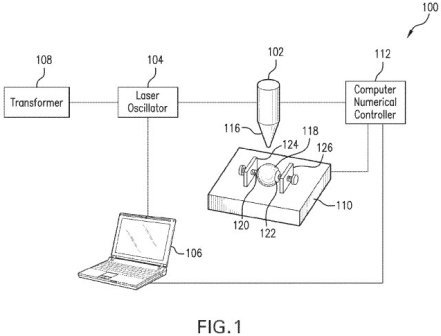

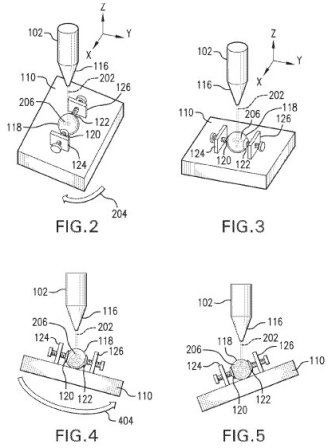

[0006] In another aspect, the disclosure provides a system for making a golf ball. The system may include a laser head configured to emit a laser beam and to move in at least one direction, a workpiece holder configured to hold and move a golf ball in at least one direction, and a computer numerical controller configured to control movement between the laser head and the workpiece. The laser head may be configured to move in three axial directions. The workpiece holder may be configured to pivot in at least two directions. The workpiece holder may include a workpiece table having a holding portion configured to hold a golf ball. The laser head may include a yttrium lithium fluoride laser head. The system may include a user interface configured to enable a user to control the laser head.

.

.

.[0042] FIGS. 7 and 8 demonstrate the results of laser cutting a plate made of polymide, a common golf ball cover material. FIG. 7 is an image of polymide plate after material has been removed by laser cutting and a detailed view of the microtexturizing resulting from laser cutting. FIG. 8 is a detailed view of the laser cut area of the polymide plate. The plate is 0.124 mm and the divot left from laser cutting material from the plate has a depth of 35 microns (0.035 mm). The range of error is about 1 micron (0.001 mm). The plate was laser cut with a Spectra-Physics Navigator II YHP40 laser system made by Spectra-Physics, a Newport Corporation brand. The laser system has a wavelength of 355 nm and a frequency of 20 kHz. 100 passes were made with the laser to cut away the material. Similar techniques may be used to remove material from the cover of a golf ball to texturize the surface of the golf ball and/or create dimples on the cover of the golf ball.

[0043] The disclosed system and method may have many applications. For example, the disclosed system and method may be used during research and development to test different types of aerodynamic patterns. During testing of different types of aerodynamic patterns, the system and method may be used to add or modify dimples to a pre-made golf ball. During testing of different types of aerodynamic patterns, the system and method may be used to add or modify dimples to a testing golf ball. For example, testing golf balls may include those described in U.S. patent application Ser. No. 12/958,843, entitled Systems and Methods for Evaluating a Golf Ball Design, applied for by Fitchett and filed on Dec. 2, 2010, the disclosure of which is hereby incorporated by reference in its entirety.

[0044] In some applications, the system and method may be used during manufacture. For example, in some applications, a certain product may be produced by using the disclosed system and method. In some applications, the system and method may be used to finish a golf ball with a customized dimple pattern selected by the customer. In some applications, the system and method may be used by a retailer for ball fitting analysis. For example, the system and method may be used for the ball fitting analysis method disclosed in U.S. Patent Application Publication Number 2011/0009215, entitled Method and System for Golf Ball Fitting Analysis, applied for by Ichikawa and published on Jan. 13, 2011, the disclosure of which is hereby incorporated by reference in its entirety.

David Dawsey – Keeping an Eye on Golf Ball Inventions

PS – Follow me on Twitter (@GolfPatents) to receive the latest golf patent updates

Comments