Do Golfers Really Want to Customize Their Balls? Nike Golf Must Think So

The simple fact is that it is easy for a golfer to tweak the settings on a modern adjustable golf club, yet 90%+ of golfers will never change a setting. What does that tell us about the likely market for golf balls that have to be tweaked/assembled by a golfer in order to use the product?

I am usually all for unconventional thinking regarding golf inventions; after all, while they may seem crazy now, they could be a billion dollar product in 15 years. Heck, I hardly chuckled at the thought of making golf balls in my kitchen, using golf balls to fight green house gases, an inflatable golf ball, a playable floating golf ball, a ball with adjustable tackiness, or a smoking golf ball, but I have to draw the line somewhere and acknowledge that a recent Nike golf ball invention suggests that they have lost their grip on reality.

The invention is disclosed in a patent application that published this week as US Pub. No. 20130225332 titled "Customizable Golf Ball And Method Of Providing A Customizable Golf Ball," which describes the invention as:

Can you imagine spending the time to assemble this golf ball puzzle and then lose it on your first shot? I would go nuts.

I think the more accurate representation of a golfer assembling their custom golf ball is something like this:

Crazy stuff! It may be time for someone to shorten the leash on the crew in golf ball R&D.

David Dawsey – Keeping an Eye on Golf Ball Patent Applications

PS – Follow me on Twitter (@GolfPatents) to receive the latest golf patent updates

I am usually all for unconventional thinking regarding golf inventions; after all, while they may seem crazy now, they could be a billion dollar product in 15 years. Heck, I hardly chuckled at the thought of making golf balls in my kitchen, using golf balls to fight green house gases, an inflatable golf ball, a playable floating golf ball, a ball with adjustable tackiness, or a smoking golf ball, but I have to draw the line somewhere and acknowledge that a recent Nike golf ball invention suggests that they have lost their grip on reality.

The invention is disclosed in a patent application that published this week as US Pub. No. 20130225332 titled "Customizable Golf Ball And Method Of Providing A Customizable Golf Ball," which describes the invention as:

The present disclosure is directed to a golf ball and a method for providing a golf ball that is customizable by a golfer to achieve a golfer's desired playing characteristics. The customizable golf ball includes multiple layers of customizable thermoplastic or thermoset materials in varying hardness levels that may be assembled by the golfer to achieve a desired feel in play. After play, the customizable golf ball may be disassembled to again vary the playing characteristics of the ball by substituting layers of varying hardness levels, or to simply replace old or worn out parts.The application goes on to explain:

BACKGROUND

[0001] The present disclosure relates generally to a customizable golf ball and a method for providing a customizable golf ball to a golfer.

[0002] Golf is a sport that enjoys wide popularity around the world and is played by golfers of all ages, from young to old. To aid and improve their performance, golfers continually search for and adopt the best and newest equipment, including golf clubs, golf balls, apparel and training devices. To that end, there are many equipment choices available, including a number of different golf ball brands and types, each designed to exhibit certain characteristics in play. Golfers typically buy golf balls in a finished state, i.e. ready-to-use, and select a ball that is most suitable for a desired combination of performance characteristics or that is designed for their skill level.

.

.

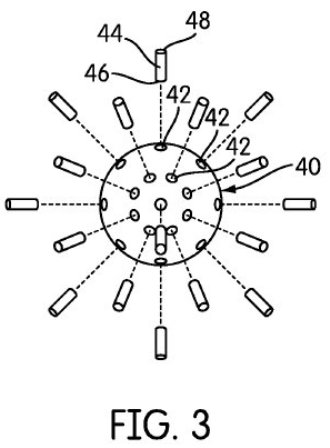

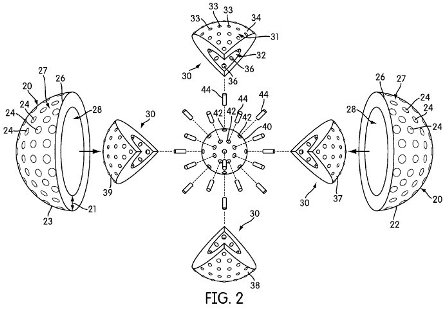

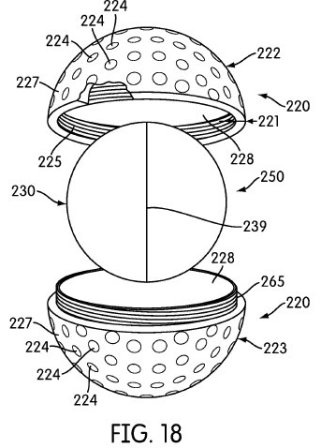

.[0038] As depicted in the exploded view of golf ball 10 in FIG. 2, an embodiment of customizable golf ball 10 exhibits a layered structure having (a) a cover 20 that forms an exterior portion of golf ball 10, (b) an optional intermediate layer or mantle shell 30 located under cover 20, and (c) an internal core 40 that forms an interior portion of ball 10. According to an embodiment set forth herein, golf ball 10 may also include a plurality of tenons 44 situated in apertures or core mortises 42 on core 40 as well as in mantle mortises 36 on an interior surface 32 of mantle shell 30. As discussed in more detail below, a golfer may customize golf ball 10 by selecting layers of varying materials and varying hardnesses to achieve desired performance or playing characteristics, such as feel, spin, velocity or trajectory.

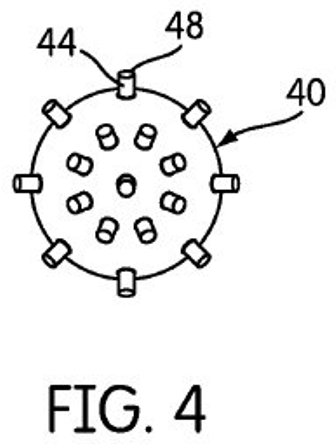

[0039] According to at least one embodiment, the internal core 40 may comprise a solid spherical structure with a plurality of core apertures 42 spaced evenly over the surface of core 40 for receiving a plurality of cylindrical tenons 44, as shown in FIGS. 3 and 4. Core apertures 42 may be sized and shaped to receive similarly sized and shaped tenons 44. Tenons 44 may be cylindrically shaped with a first end 46 placed in an aperture 42 on core 40 and a second end 48 placed in a similarly sized and shaped aperture 36 on an interior surface 32 of mantle shell 30, as further set forth below. Those skilled in the art will appreciate that the number of tenons 44 may be fewer or more than is depicted in FIGS. 3 and 4 and still achieve the desired effect, described below. Furthermore, those skilled in the art will readily appreciate that the tenon/mortise construction may also be achieved using a variety of different shapes, such as triangular-shaped tenons, rectangular-shaped tenons, pentagonal-shaped tenons, hexagonal-shaped tenons, or other kind of polygonal-shaped tenons, without altering the spirit and scope of the customizable golf ball set forth herein.

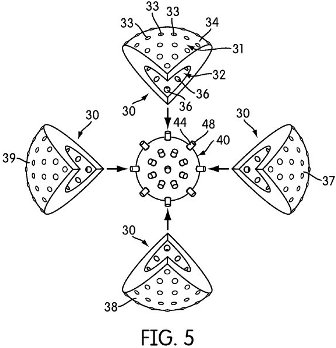

[0040] Referring to the embodiment of FIGS. 5 and 6, mantle shell 30 may be comprised of four quarter-sphere pieces, first quarter-sphere piece 34, second quarter-sphere piece 37, third quarter-sphere piece 38, and fourth quarter-sphere piece 39. FIG. 5 depicts an exploded view of how mantle shell 30 may be placed over core 40 and FIG. 6 depicts the two layers in place together. Mantle shell 30 may also comprise two half-sphere pieces as shown in the embodiments depicted in FIGS. 11-16, discussed below. Mantle shell 30 has an exterior surface 31 and an interior surface 32 that is sized and shaped to mate with internal core 40. In the embodiment depicted in FIGS. 5 and 6, interior surfaces 32 of first quarter-sphere piece 34, second quarter-sphere piece 37, third quarter-sphere piece 38, and fourth quarter-sphere fourth quarter-sphere piece 39 exhibit a plurality of spaced apart cylindrically-shaped mantle apertures 36 that are sized and shaped to receive cylindrically-shaped tenons 44 protruding from core 40. When fitted together as seen in FIG. 6, core 40, tenons 44 and mantle shell 30 together create a tenon and mortise construction, and first quarter-sphere piece 34, second quarter-sphere piece 37, third quarter-sphere piece 38, and fourth quarter-sphere piece 39 of mantle shell 30 fit together along seam line 12 and seam line 14.

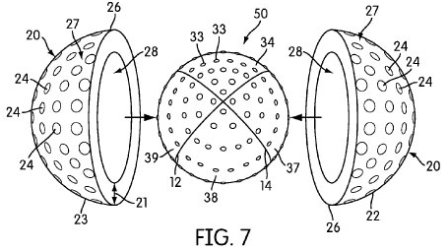

[0041] The exterior surface 31 of mantle shell 30 may also include provisions that can impact the ball's structure, according to aspects set forth herein. For example, the exterior surface 31 of mantle shell 30 may include small projections 33 to assist with positioning cover 20 over mantle shell 30. In the embodiment shown in FIGS. 5-7, projections 33 create small spherical protrusions on the exterior surface 31 of mantle shell 30. It should be understood that projections 33 may be sized and shaped in a variety of manners, or may be absent altogether, and still meet the spirit and scope of the present disclosure.[0042] After core 40 is covered by mantle shell 30 to form a complete inner ball 50 as in FIGS. 6 and 7, inner ball 50 may be covered by two dimpled cover shells 22 and 23. FIG. 7 depicts an exploded view of how cover 20 may be placed over inner ball 50 to create finished golf ball 10 (as seen in FIG. 1). Cover 20 has an exterior surface 27 separated from an interior surface 28 by a thickness 21 selected to allow the interior surface to mate with inner ball 50. In particular, thickness 21 may be decreased or increased based on the size of inner ball 50. In the embodiment depicted in FIGS. 5 and 6, interior surfaces 28 are smooth, and projections 33 on inner ball 50 may be pressed against interior surfaces 28; however, in other embodiments, interior surfaces 28 may have impressions that are sized and shaped to receive projections 33. When fitted together as seen in FIGS. 1 and 7, first cover piece 22 and second cover piece 23 come together at seam line 26. Referring to FIG. 7, seam line 26 of cover 20 may be offset from seam line 12 and seam line 14 of mantle shell 30 to increase durability across the layers of golf ball 10.

.

.

.

[0045] According to the present disclosure, the surface hardness level relationship between the layers of golf ball 10 may be dictated by the golfer assembling the customizable ball (assembly discussed in further detail below).

[0046] To achieve a variety of desired playing characteristics, a golfer may customize golf ball 10 by using materials of varying hardness levels for the multiple layers of golf ball 10. For example, tenons 44 may have the same or a different surface hardness level from that of core 40 and mantle shell 30. Likewise, projections 33 on mantle shell 30 may have the same or a different surface hardness level from that of mantle shell 30. In addition, the hardness level of core 40 tenons 44 and mantle shell 30 may each be higher or lower in relation to the hardness level of cover 20. As is known in the art, the variation in hardness levels among the multiple layers can create a different feel when the ball is hit. A golfer may customize the feel of golf ball 10 to his/her particular skill level or liking by using layers of varying hardness levels, varying thicknesses or varying materials throughout golf ball 10.

.

.

.

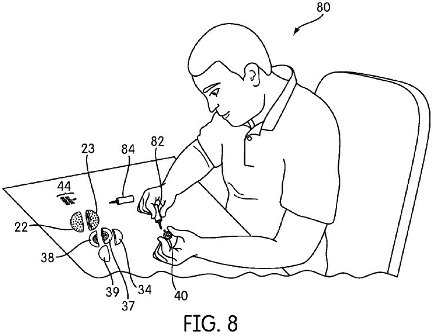

[0048] FIG. 8 depicts a golfer 80 in the beginning stages of assembling a customizable golf ball 10, i.e., joining a tenon 44 to core 40, according to at least one embodiment set forth herein. Also present in FIG. 8 are additional layers of golf ball 10 that have not yet been fully assembled, i.e., mantle shell first quarter-sphere piece 34, mantle shell second quarter-sphere piece 37, mantle shell third quarter-sphere piece 38, mantle shell fourth quarter-sphere piece 39, first cover piece 22, and second cover piece 23, as well as an adhesive 82 and solvent 84. According to aspects set forth herein, golfer 80 may join the multiple layers together using adhesive 82, such as a thermoplastic adhesive, or by other suitable method as is well-known in the art. This may include placing ends 46 of tenons 44 in core apertures 42 and joining by adhesive 82, as well as by placing mantle apertures 36 of mantle shell 30 over ends 48 of tenons 44 and joining by adhesive 82. After internal ball 50 is assembled by joining core 40, tenons 44 and mantle shell 30, golfer 80 may join first cover piece 22 and second cover piece 23 to form a cover 20 of golf ball 10 such that a seam line 26 is offset from seam line 12 and seam line 14 (or any other seam line created by a mantle shell layer). After cover 20 is secured, a golfer may also apply a top coating to the cover as is known in the art. After assembly, golf ball 10 may be ready for play by golfer 80 as shown in FIG. 9.

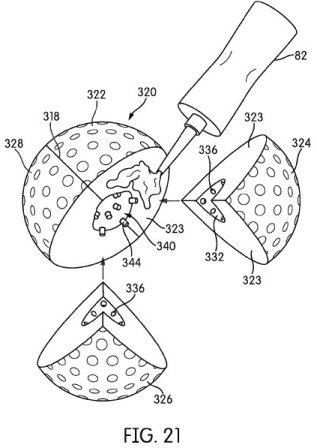

[0049] According to aspects set forth herein, customizable golf ball 10 may also be disassembled after play to replace existing layers with layers of a varying material or hardness layer to achieve a different feel, or simply to replace old or worn out parts or layers. FIG. 10 depicts golfer 80 beginning disassembly of golf ball 10 by applying a solvent 84 to seam 26 of cover 20 to remove cover 20 from inner ball 50. Solvent 84 may be any solvent suitable for reversing the adhesive properties of an adhesive used during assembly, as would be readily known to those of skill in the art. Examples of solvents include but are not limited to water, alcohols, and acid compounds such as vinegar. In addition, a golfer may reverse adhesive properties by other known means, such as exposure to heat or other types of radiation, such as microwaves.[0074] Similar to previously discussed embodiments, FIG. 21 depicts an exploded view of how cover 320 may be placed over core 340 to create finished golf ball 310 (as seen in FIG. 22). In particular, according to aspects set forth herein, a golfer may join the multiple layers together using an adhesive 82, such as a thermoplastic adhesive, or by other suitable method as is well-known in the art. This may include placing ends 346 of tenons 344 in core apertures 342 and joining by adhesive 82 to create an assembled core 340. After assembled core 340 is constructed, a golfer may place cover apertures 336 of each quarter-sphere of cover 330 over ends 348 of tenons 344, joining each quarter-sphere of cover 320 both to core 320 and an adjoining quarter-sphere. As may be seen in FIG. 21, adjoining flat surfaces 323 of seventh cover piece 322, eighth cover piece 324, ninth cover piece 326 and tenth cover piece 328 may be joined together and sealed with adhesive 82. After cover 320 is secured, a golfer may also apply a top coating to the cover as is known in the art (not shown).

Can you imagine spending the time to assemble this golf ball puzzle and then lose it on your first shot? I would go nuts.

I think the more accurate representation of a golfer assembling their custom golf ball is something like this:

Crazy stuff! It may be time for someone to shorten the leash on the crew in golf ball R&D.

David Dawsey – Keeping an Eye on Golf Ball Patent Applications

PS – Follow me on Twitter (@GolfPatents) to receive the latest golf patent updates

Comments