An Iron Invention for All the Forged-Iron Snobs

You know who you are. The guy at the club that has an index of 5, doesn’t post any scores over 85 although 75% of their scores are over 85, plays to an index of 20+, is always “working through” a swing change, and insists that he needs a forged iron because he likes to “work” the ball and can feel the difference in a cast head, or even the feel of a grain-flow forged head versus a form-forged head versus a traditional forged head. As annoying as this vanity-handicapping, swing-coach obsessed, flat-bill wearing, collar-popping group of golfers is, the golf industry needs them. They are the cash cows of golf consumers.

A recently published Acushnet patent application will have these players salivating, and for good reason, the invention sounds great (particularly for such highly skilled golfers). Unfortunately I suspect this may be one of those inventions that is a lot easier to explain on paper than it is to carry out in the factory.

The application (US Pub. No. 20130137532) describes the invention as:

The application goes on to explain:

Are you buying the statement “post manufacturing machining causes bad feel?” Not me, but it has the potential of being a pretty unique iron (if they can pull it off). Place your bets, will a co-forged Titleist iron make it to the market in the next 5 years?

Dave Dawsey - The IP Golf Guy

PS - I admit to playing forged irons but not because I can feel any difference, because the ladies love them (of course).

A recently published Acushnet patent application will have these players salivating, and for good reason, the invention sounds great (particularly for such highly skilled golfers). Unfortunately I suspect this may be one of those inventions that is a lot easier to explain on paper than it is to carry out in the factory.

The application (US Pub. No. 20130137532) describes the invention as:

A co-forged iron type golf club is disclosed. More specifically, the present invention discloses a co-forged iron type golf club with the body portion made out of a first material and at least one weight adjustment portion monolithically encased within the body portion of the co-forged iron type golf club head without the need for secondary attachment or machining operations. The present invention creates of an iron type golf club head from a pre-form billet that already contains two or more materials before the actual forging process resulting in a multi-material golf club head that doesn't require any post manufacturing operations such as machining, welding, swaging, gluing, and the like.

The application goes on to explain:

BACKGROUND OF THE INVENTION

[0002] Golf is hard! When your average golfer swings a golf club, he or she may have dramatic variations in his or her golf swing, resulting in numerous off-center hits, which result in diminished performance when compared to a direct center hit. However, in an attempt to make this very difficult game more enjoyable for the average golfer, golf club designers have came up with unique golf club designs that will mitigate the harsh realities of a less than perfect golf swing.

.

.

.

[0005] Although the initial attempts at increasing the forgiveness and playability of a golf club for an average golfer are admirable, it does not take advantage of the extreme forgiveness that can be achievable by utilizing different materials to form different portions of the golf club head. In one example, U.S. Pat. No. 5,885,170 to Takeda shows the advantage of using multi-materials to create more extreme adjustment of the mass properties. More specifically, U.S. Pat. No. 5,885,170 teaches a body having a face formed of one material while a hosel is formed from another material having different specific gravity from that of the head body. U.S. Pat. No. 6,434,811 to Helmstetter et al. shows another example of utilization of multiple materials to improve the performance of a golf club head by providing a golf club head with a weighting system that is incorporated after the entirety of the golf club head has been formed.

[0006] More recently, the improvements in incorporating multi-materials into a golf club head has matured significantly by incorporating numerous multiple materials of different characteristics by machining cavities into the golf club head. More specifically, U.S. Pat. No. 7,938,739 to Cole et al. discloses a golf club head with a cavity integral with the golf club head, wherein the cavity extends from the heel region to the toe region; extending along a lower portion of the back face of the golf club head; extends approximately parallel to the strike face; and is approximately symmetrical about a centerline that bisects the golf club head between the heel region and the toe region.

[0007] However, as multiple materials are introduced into the golf club after the body has been completed, the tolerances of the interfaces between the different materials could potentially cause undesirable side effects of altering the feel of the golf club head. U.S. Pat. No. 6,095,931 to Hettinger et al. identifies this specific undesirable side effect of sacrifice in the feel by the usage of multiple different components. U.S. Pat. No. 6,095,931 addresses this issue by providing an isolation layer between the golf club head and the main body portion that comprises the striking front section.

[0008] U.S. Pat. No. 7,828,674 to Kubota recognizes the severity of this problem by stating that hollow golf club heads having viscoelastic element feels light and hollow to the better golfer, hence they do not prefer such a golf club. U.S. Pat. No. 7,828,674 address the deficiencies of such a multi-material golf club by incorporating a block of magnesium to be embedded and or press-fitted into the recess formed in the metal only to be sealed with a metallic cover.

[0009] Despite all of the above attempts to improve the performance of a golf club head all while trying to minimize the sacrifice in feel of a golf club, all of the methodologies require a significant amount of post manufacturing operation that creates cavities and recesses in the club head for the secondary material to be incorporated. These type of secondary operations are not only expensive, but the ability to maintain a tight enough tolerance between the various components make is very difficult to maintain the solid feel generally associated with an unitarily formed golf club head.

[0010] Hence, it can be seen from above, despite all the development in creating a golf club head that's more forgiving without sacrificing the feel associated with a conventional club head, the current art is incapable of creating such a club without utilizing severe post manufacturing machining that causes bad feel.

.

.

.

[0023] FIG. 1 of the accompanying drawings shows a perspective view of a golf club head 100 in accordance with an exemplary embodiment of the present invention. The golf club head 100 shown in FIG. 1 may generally comprise of a body portion 102 and a hosel portion 104, with the body portion 102 having several individually identifiable components such as a topline portion 106, a sole portion 108, a heel portion 110, and a toe portion 112. The golf club head 100 in accordance with an exemplary embodiment of the present invention may generally be comprised of at least one weight adjustment portion that is encased within the body portion 102 of the golf club head 100. In a preferred embodiment, the weight adjustment portion may be monolithically encased within the body portion 102 to ensure that the weight adjustment portion is secured within the body portion 102 without departing form the scope and content of the present invention. Because the weight adjustment portion is monolithically encased within the body portion 102 of the golf club head 100, these weights are not visible in FIG. 1 of the accompanying drawings. However, these weight adjustment portions will be shown in more detail in later figures, when various different views are presented.

[0024] Before moving onto subsequent figures, it is worthwhile here to emphasize that the current golf club head 100 is created using a forging process and the weights are incorporated without any post finish machining operations. This is an important distinction to establish because the same result of a monolithically encasing a weight adjustment portion is extremely difficult to achieve using alternative manufacturing processes such as casting. "Monolithically encased", as referred to in the current patent application, may generally be defined as a having a specific internal component placed inside a separate external component without joints or seams in the finished product. With respect to the current invention, having weight adjustment portions "monolithically encased" within the body portion 102 of the golf club head 100 may generally refer to the ability to have weight adjustment portions placed inside the body portion 102 of the golf club head without joints or seams that are generally required by post manufacturing processes such as milling, welding, brazing, gluing, or swaging.

[0025] It should also be noted here that a weight that is "monolithically encased" within the current definition of the present invention could potentially have certain aspect of the internal weights exposed in the finish product to illustrate the existence of a weight adjustment portion without departing from the scope and content of the present invention. More specifically, "monolithically encased" refers to the methodology used to create the ultimate product as described above, and may not necessarily be limited to visually concealing the weight adjustment member.

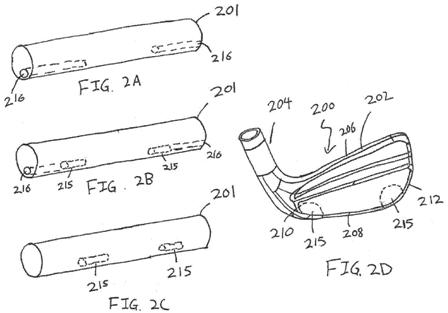

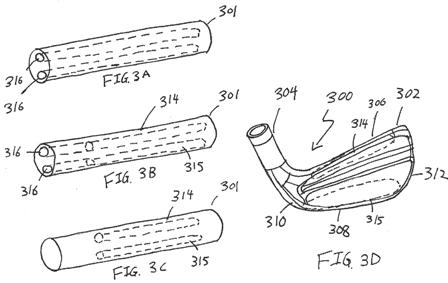

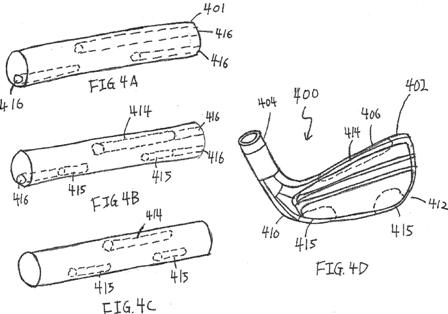

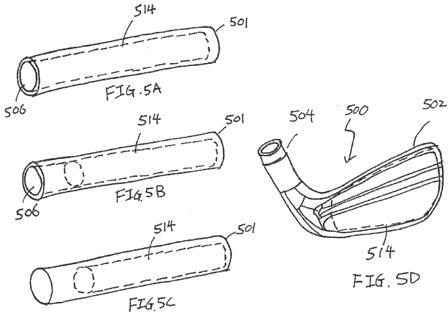

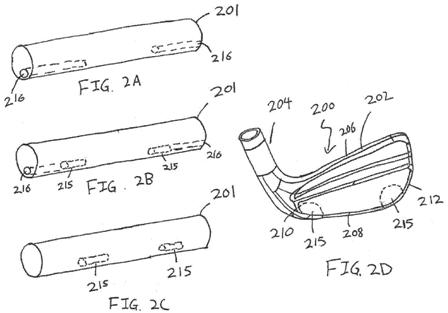

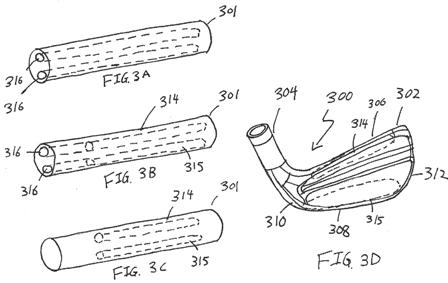

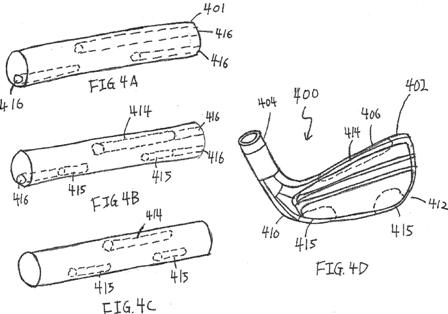

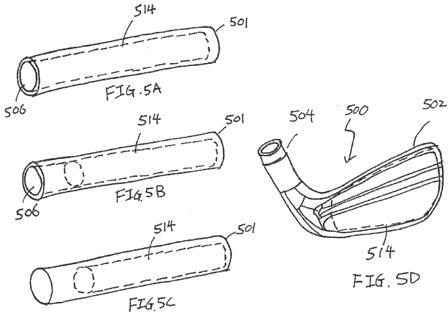

[0026] FIGS. 2A-2D illustrate the methodology used to create a co-forged golf club head 200 in accordance with an exemplary embodiment of the current invention. More specifically, FIGS. 2A-2D illustrate the steps involved in the forging of a golf club head from its rudimentary billet 201 shape into the final product of a golf club head 200.

[0027] FIG. 2A shows a pre-formed billet 201 in accordance with an exemplary embodiment of the present invention. As it can be seen from FIG. 2A, the pre-form billet 201 may generally begin as a cylindrical rod formed from a first material, as it is common with the forging of a golf club head 200. In order to create a weight adjustment portion 215 that can be monolithically encased within the body portion 202 of the golf club head 200, one or more cavities 216 are machined into the pre-form billet 201. In this current exemplary embodiment shown in FIG. 2A, two cavities 216 are machined into the terminal ends of the pre-form billet 201. The location and geometry of the cavities 216 within the pre-form billet 201 are important, as it correlates directly with the ultimate location of the weight adjustment portion 215 in the golf club head 200 after forging.

[0028] Moving onto FIG. 2B, it can be seen that once the cavities 216 are machined, the cavities 216 are partially filled with a second material that has a density different from the density of the first material in order to create the weight adjustment portion. 215. Similar to the discussion above, the location, size, and shape of the weight adjustment portion 215 is just as critical as the location, size, and shape of the cavities 216, as the weight adjustment portion 215 within the pre-form billet 201 correlates with the ultimate resting place of the weight adjustment portion 215 in the golf club head.

[0029] Finally, FIG. 2C shows the final phase of the pre-form billet 201 as the remaining volume of the cavities 216 are filled with the first material and sealed through traditional joining methods such as welding, brazing, and swaging. Sealing the cavities 216 allows the weight adjustment portion 215 to be monolithically encased within the body of the pre-form billet 201, which will allow the same weight adjustment portion 215 to be monolithically encased in the body 202 of the golf club head 200 after the forging process. After the cavities 216 are filled, the pre-form billet 201 is subjected to the normal forging process associated with the forging of a golf club head 200. Although the basic steps involved in forging a golf club head 200 are important to the understanding of the current invention, it involves a relatively archaic and established technique, which the present application will not dive into much detail. More information regarding the steps involved in the forging of a basic golf club head without monolithically encased weight adjustment portions can be found in U.S. Pat. No. 3,825,991 to Cornell, and U.S. Pat. No. 6,666,779 to Iwata et al., the disclosure of which are all incorporated by reference in its entirety.

[0030] Although the above discussion regarding the forging of a golf clubs incorporated by reference do a good job describing the actual forging process, it fails to address the additional concerns with the co-forging process of the current invention wherein two different materials are involved in this forging process. More specifically, because a weight adjustment portion 215 is made out of a second material that could be different from the first material used to create remainder of the pre-form billet 201, special care must be taken to ensure that the different materials can be forged together to form a golf club head 200. Hence, in order to select two cohesive materials that are capable of being co-forged together, the first material and the second material may generally have to have very specific material properties requirements with respect to their flow stress and their thermal expansion coefficient. Although it is most preferential for the two materials to have identical material properties yielding in consistency in forging, the usage of identical materials may not offer any weight adjustment benefits required for the basis of the current invention.

Are you buying the statement “post manufacturing machining causes bad feel?” Not me, but it has the potential of being a pretty unique iron (if they can pull it off). Place your bets, will a co-forged Titleist iron make it to the market in the next 5 years?

Dave Dawsey - The IP Golf Guy

PS - I admit to playing forged irons but not because I can feel any difference, because the ladies love them (of course).

Comments