What's Next in Adjustability? Perhaps Adjustable Grooves by Nike Golf

A golf club head which may include a golf club head body, a ball striking face and a piezoelectric member in the golf club head, wherein the piezoelectric member is configured to be selectively adjusted by an input provided through a controller operably connected to the piezoelectric member. Further, the piezoelectric member may be capable of having a first configuration to provide the golf club head body with a first attribute and may also be capable of having a second configuration to provide the body with a second attribute in response to the input provided by the controller. Further, the second attribute may be different from the first attribute.

It goes on to explain:

SUMMARY OF THE INVENTION

[0006] Aspects of the disclosure may relate to a golf club head including a golf club head body, a ball striking face and a piezoelectric member in the golf club head, wherein the piezoelectric member is configured to be selectively adjusted by an input provided through a controller operably connected to the piezoelectric member. Further, the piezoelectric member may be capable of having a first configuration to provide the golf club head body with a first attribute and may also be capable of having a second configuration to provide the body with a second attribute in response to the input provided by the controller. Further, the second attribute may be different from the first attribute.

[0007] Further, aspects of the disclosure may relate to a golf club which may include a golf club head with a golf club head body, a ball striking face and a piezoelectric member in the golf club head body. Further, the golf club may include a shaft configured to be engaged with the golf club head and a controller operably connected to the piezoelectric member. Additionally, the controller may be configured to allow the user to selectively adjust a configuration of the piezoelectric member by providing an input through the controller. Also, the piezoelectric member may be capable of having a first configuration to provide the golf club head body with a first attribute and may also be capable of having a second configuration to provide the body with a second attribute in response to the input provided by the controller, the second attribute being different from the first attribute.

.

.

.

I. General Description of Example Golf Club Heads, Golf Clubs, and Methods in Accordance with this Invention

[0029] Aspects of this disclosure relate to iron-type golf club heads. Iron-type golf club heads according to at least some example aspects of this disclosure may include: (a) an iron-type golf club head body; (b) a ball striking face; and (c) at least one piezoelectric element in the iron-type golf club head body. According to aspects of this disclosure, the one or more piezoelectric elements in the iron-type golf club head may be configured to selectively adjust attributes, characteristics or properties of the iron-type golf club head. For example, according to aspects of the disclosure, the size, shape, positioning, etc. of the one or more piezoelectric elements in the iron-type golf club head may be configured to selectively control various attributes of the iron-type golf club head, including the configuration of the grooves in the iron-type golf club head (e.g., the depth, volume, shape, angle, etc. of the grooves), the stiffness or dampening ability of the iron-type golf club head, the loft of the golf club head iron-type golf club head, etc..

.

.

[0042] According to aspects of the disclosure, the golf club head 102 may include at least one piezoelectric member 120 associated therewith. A piezoelectric member may include an element with piezoelectric properties. It is noted that an element with piezoelectric properties may generate an electrical voltage when a mechanical strain or stress is applied. Further, conversely, the element with piezoelectric properties may deform mechanically when an electric field is applied. For example, according to aspects of the disclosure, an electric field may be applied to the piezoelectric member 120 which causes a change in the configuration (e.g., the size or dimensions) of the piezoelectric member 120. For example, the size of the piezoelectric member 120 may increase (e.g., "grow") or decrease ("shrink") when an electric field is applied. Further, the size of the piezoelectric member 120 may tend to return to their original shape when the electric field is removed. Further, the amount the piezoelectric member 120 deforms (e.g., the amount the piezoelectric member 120 increases or decreases in size) during the time the electric field is applied may be dependent upon the strength of the electric field. For example, according to aspects of the disclosure, the piezoelectric member 120 may deform by a first amount (e.g., increase or decrease by a first size) if a first voltage is applied and may deform by a second, larger amount (e.g., increase or decrease by a second, larger size) if a second larger voltage is applied.

[0043] Therefore, according to aspects of the disclosure, one or more piezoelectric members 120 may be used in a the golf club head 102 to control and selectively alter various attributes, characteristics or properties of the iron-type golf club head. For example, according to aspects of the disclosure, one or more piezoelectric members 120 may be incorporated into the golf club heads 102 and an electric field may be applied to the one or more piezoelectric members 120 to selectively alter various attributes, characteristics or properties of the iron-type golf club head. It is noted that according to aspects of the disclosure, attributes may include mechanical or physical properties of the golf club head. For example, the attributes may include the configuration of the grooves in the iron-type golf club head (e.g., the depth, volume, shape, angle, etc., of the grooves); the internal stress, stiffness or hardness behind the ball striking face of the golf club head; the loft angle of the golf club head; etc. Further, it is noted that attributes may affect the trajectory of the golf ball after impact with the golf club head (e.g., by affecting how the golf ball leaves off the ball striking face of the golf club head). For example, the attributes may affect the trajectory of the golf ball after impact with the golf club head by affecting the backspin of the golf ball, the lofted flight of the golf ball, etc.

[0044] According to aspects of the disclosure any element with piezoelectric properties may be used as the piezoelectric member 120. For example, according to aspects of the disclosure, polymers having piezoelectric properties may be used as the piezoelectric member 120. By way of example, polyvinylidine diflouride (PVDF) is an element with piezoelectric properties that may be used as the piezoelectric member 120 in accordance with aspects of the disclosure.

[0045] According to aspects of the disclosure, and as seen in FIG. 3, the golf club head 100 may include a controller 122 for activating the piezoelectric member 120 associated with the golf club head 120. For example, as shown in FIG. 3, the shaft 107 may be configured to support the controller 122. According to aspects of the disclosure, the controller 122 may be operably connected to the piezoelectric member 120. For example, the controller 122 may include wires which transmit the electric field (e.g., via an electric current) from a power source (e.g., a battery) to the piezoelectric member 120. Other various types of conductors can also be used.

[0046] According to aspects of the disclosure, the controller 122 may include a switch, a knob, or dial, 124 which may be configured to rotate to control the electric field applied to the piezoelectric material 120. For example, the knob 124 may be configured to be rotated from a first (e.g., "off") position, wherein no electric field is generated, to a second (e.g., "on") position, wherein an electric field is generated and applied to the piezoelectric material 120. According to aspects of the disclosure, upon the electric field being generated and applied to the piezoelectric material 120, the size of the piezoelectric member 120 may be increased or decreased as discussed above. Conversely, when the knob 124 is rotated back to the off position and the electric field is removed, then as discussed above, the size of the piezoelectric member 120 may decrease or increase back to its original size.

[0047] Further, according to aspects of the disclosure, the controller 122 may be configured to vary the strength of the electric field (e.g., the amount of voltage) applied to the piezoelectric material 120. For example, according to aspects of the disclosure, the knob 124 may be configured to rotate between various positions, which, in turn, increase or decrease the strength of the electric field. For example, one position to which the knob 124 may be rotated may correspond to a voltage of 1.5V, a second position to which the knob 124 may be rotated may correspond to a voltage of 3.0V, etc. In this way, the golfer may selectively adjust the size of the piezoelectric material 120 and, thereby, selectively alter and control various attributes, characteristics or properties of the iron-type golf club head. It is noted that the above voltages are merely illustrative and other voltages may be applied as desired.

[0048] As seen in FIG. 3, the shaft 106 may include a compartment configured to receive a battery or other power source. Further, according to aspects of the disclosure, the controller 122 may be configured to be connected to the one or more power source (e.g., through one or more of leads connected to the battery or power source) in order to apply the electric field to the piezoelectric material 120. According to aspects of the disclosure, a portion of the shaft 106 (e.g., the handle 107) may be removeably engaged with the remainder of the shaft 106 (e.g., through threads or other mechanical connectors) in order to allow access to the battery or power supply (e.g., to insert or replace the battery or power supply).

[0049] According to aspects of the disclosure, the piezoelectric member 120 may be activated by the hand or grip of the golfer when the golfer grips the golf club 100. For example, according to aspects of the disclosure, the golf club 100 may include a button or switch (e.g., a button or switch positioned at or near the handle 107) that is depressed or otherwise activated (e.g., a switch activated by pressure) when the golf grips the golf club 100. By activating the button, the electric field may be applied to the piezoelectric member 120 (e.g., through wires running through the shaft 106) to deform the piezoelectric member 120 (e.g., to increase or decrease the size of the piezoelectric member 120). For example, when the button is depressed, a circuit may be completed through which the electric field may be applied to the piezoelectric member 120. Further, it is noted that according to such an embodiment of the golf club 100, the knob 124 may be incorporated to modify the voltage applied to the piezoelectric member 120 as described above.

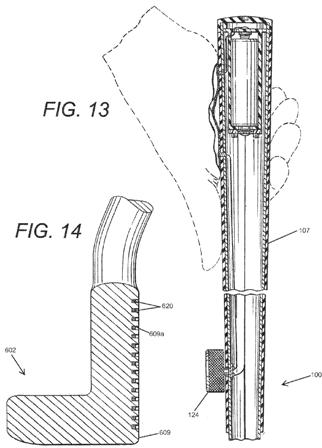

[0050] Alternatively, the golfer may wear a glove which could include an external power source or other structure designed to complete a circuit to activate the piezoelectric member. FIG. 13 shows a cross-sectional view of the golf club 100 in which an illustrative embodiment such a controller 122 is configured. As seen in FIG. 13, according to aspects of the disclosure, the golf club 100 may include exposed portions (e.g., a switch, electrical lead, etc. positioned at or near the handle 107). The glove may include a material that will serve to complete a circuit that activates the piezoelectric member 120. For example, the glove may include a conducting material positioned on the exterior of the palm of the glove. Thereby, when the golfer grips the handle, the conducting material engages the exposed leads and completes the circuit through which the electric field may be applied to the piezoelectric member 120. Conversely, the golfer releases the handle, the circuit is opened and, consequently, the electric field may be removed from the piezoelectric member 120.

[0051] According to particular aspects of the disclosure, the glove may contain the power source (e.g., a battery) instead of (or in addition to) the golf club 100. For example, the glove may contain a battery through which the electric field may be applied to the piezoelectric member 120 when the golfer grips of the handle and the conducting material engages the exposed leads and completes the circuit. According to aspects of the disclosure, the battery may be in contact with the leads in order to complete the circuit and apply the electric field to the piezoelectric member 120. Alternatively, the battery may contact wires or other conducting material positioned on the exterior of the glove, which in turn contacts the leads in order to complete the circuit and apply the electric field to the piezoelectric member 120.

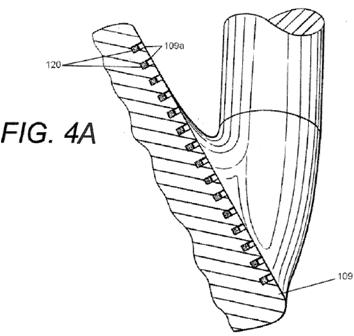

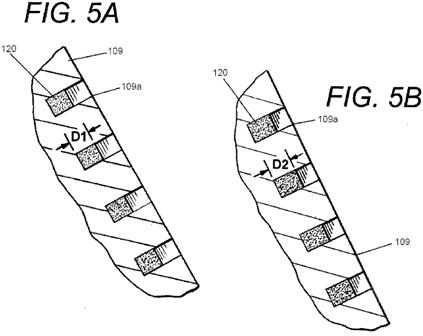

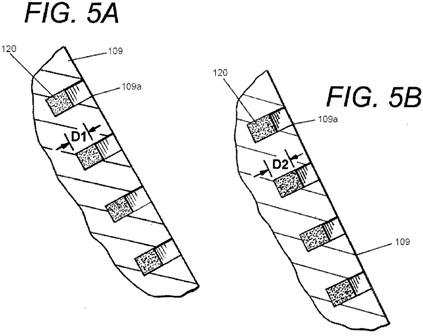

[0052] FIGS. 4A, 4B, 4C, 5A and 5B show various views of the illustrative embodiment of the golf club head 102 according to aspects of the disclosure. According to aspects of the disclosure and as illustrated in the embodiment shown in FIGS. 1, 3, 4A, 4B, 4C, 5A and 5B, piezoelectric material may be configured within the golf club head 102 to control the depth of the grooves 109a of the golf club head 102. Hence, as will be discussed below, according to aspects of the disclosure, the piezoelectric member 120 may be used to selectively control and adjust the depth of the grooves of the golf club head 102 and, thereby, the amount of backspin imparted to the golf ball by the golf club head 102 and also the launch angle and ball speed.

[0053] Specifically, FIG. 4A is a partial cross-sectional view of the golf club head body taken along lines 4-4 shown in FIG. 1. FIG. 4B is a partial cross-sectional view of the golf club head body. FIG. 4C is a partial cross-sectional view of the golf club head body according to another embodiment of the disclosure. FIG. 5A is a partial enlarged cross-sectional view of the golf club head body shown in FIG. 4, and showing a piezoelectric member in a first position. FIG. 5B is another partial enlarged cross-sectional view of the golf club head body shown in FIG. 5A, and showing the piezoelectric member in a second position.

[0054] In order to describe the features of the illustrative golf club head 102, a figure of a conventional golf club head is provided for reference at FIG. 2. FIG. 2 is a partial cross-sectional view of a conventional golf club head body 1000. As seen in FIG. 2, the conventional golf club head has grooves which extend in a horizontal direction (i.e., a heel to toe direction) across the golf club head body.

[0055] In contrast to the conventional golf club head shown in FIG. 2, the illustrative golf club head 102 shown in FIG. 4A, may include one or more piezoelectric members 120. For example, as seen in FIG. 4A, the piezoelectric members 120 may be positioned to extend through the grooves 109a in the ball striking face 109 of the golf club head 102. For example, the piezoelectric members 120 may be configured as strips which extend substantially or entirely through the length of grooves 109a (e.g., a heel to toe direction) in the ball striking face 109 of the golf club head 102. It is noted that the piezoelectric members 120 may have other configurations as well. For example, the piezoelectric members 120 may be connected by a continuous plane of piezoelectric material parallel to the ball striking face 109 (e.g., a face plate). For example, the continuous plane of piezoelectric material may be positioned at the rear of the piezoelectric members 120 so as to connect the piezoelectric members 120. The continuous plane of piezoelectric material may extend throughout some, or all, of the golf club head 102 at a position behind ball striking face 109.

[0056] As described above, according to aspects of the disclosure, the electric field may be applied to the piezoelectric member 120 through wires running through the shaft 106 to deform the piezoelectric member 120. FIGS. 3 and 13 show such illustrative embodiments. Further, FIG. 4B is an illustrative embodiment of such a structure according to aspects of the disclosure. As seen in cross-sectional view shown in FIG. 4B, each of the piezoelectric member 120 may be connected to a lead or wire 140 through which the electric field may be applied to the piezoelectric member 120. The lead or wire 140 may be connected to the battery in the handle 107, such as shown in FIG. 3. For example, each lead or wire 140 may be a branch of the wire that runs along the shaft of the golf club 100 as seen in FIG. 3. It is understood that the lead or wire 140 may be employed in various alternative configurations that will allow a suitable electrical field to be applied to the piezoelectric member. It is further understood that the lead or wire 140 can take various conductive member configurations as necessary to impart the electrical field. It is noted that for clarity purposes, leads or wires 140 connected to piezoelectric member 120 may not be shown in various other cross-sectional views throughout the application.

[0057] It is noted that the piezoelectric members may be engaged with the golf club head 102 by any viable means, such as: adhesives, cements, welding, soldering, etc. Alternatively, the piezoelectric members may be formed integrally with the golf club head 102. According to aspects of the disclosure piezoelectric members may be injected into the golf club head 102. For example, the piezoelectric material may be injected into cavities in the golf club head 102 that are configured to receive such piezoelectric material. Further, according to aspects of the disclosure the golf club head 102 and the piezoelectric members may be configured so that the engagement between the golf club head 102 and the piezoelectric members retains the piezoelectric members within the golf club head 102. For example, FIG. 4C is an illustrative embodiment of such a structure according to aspects of the disclosure. As seen in FIG. 4C, each of the piezoelectric member 120 may be configured with a dovetail shape. Further, the golf club head 102 may include a corresponding cavity configured to engage with the dovetail shape of the piezoelectric member 120. Thereby, such engagement between the golf club head 102 and the piezoelectric members 120 retains the piezoelectric members within the golf club head 102. It is noted that other structures of the piezoelectric material and cavities may be used as well (e.g., other shapes for retaining the piezoelectric material within the golf club head 102).

[0058] FIG. 5A illustrates the piezoelectric members 120 in the golf club head 102 in a first position (e.g., an original state) when no electric field has been applied to the piezoelectric members 120. As seen FIG. 5A, the piezoelectric members 120 have a first size which includes a depth of D1. In contrast, FIG. 5B illustrates the piezoelectric members 120 in the golf club head 102 in a second position (e.g., a deformed state) when an electric field has been applied to the piezoelectric members 120. As seen FIG. 5B, the piezoelectric members 120 have a second size which includes a depth of D2 which is greater than D1. Hence, the volume of the grooves 109a of the golf club head is reduced. Therefore, it is understood, that according to aspects of the disclosure, the volume of the grooves 109a of the golf club head 102 may be controlled (e.g., increased and deceased) by manipulating the piezoelectric members 120 positioned in the grooves 109a in the ball striking face 109 of the golf club head 102 (e.g., by applying an electric field to the piezoelectric members 120).

..

.

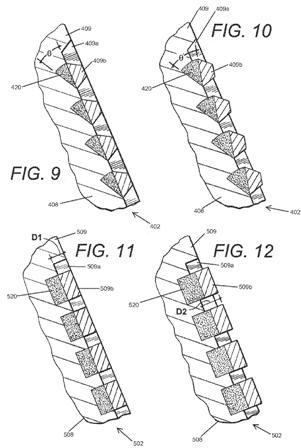

[0078] It is noted that several features of the embodiment shown in FIGS. 9 and 10 are similar to the embodiments described above and, therefore, for the sake of brevity will not be elaborated on in detail here. However, it is noted that according to aspects of the disclosure and as illustrated in the embodiment shown in FIGS. 9 and 10, the piezoelectric members 420 may be configured within the golf club head 402 to selectively control and adjust the angle of the grooves 409a of the golf club head 402. Hence, as will be discussed below, according to aspects of the disclosure, the piezoelectric members 402 may be used to selectively control and adjust the amount of spin the golf club head 402 imparts to the golf ball during a golf shot.

[0079] As seen in the illustrative embodiment shown in FIGS. 9 and 10, according to aspects of the disclosure, the piezoelectric members 420 may be configured to be positioned behind the individual slat 409b in the ball striking face 409 which at least in part defines the grooves 409a of the ball striking face 409 of the golf club head 409. For example, as seen in FIGS. 9 and 10, the piezoelectric members 420 may be configured to extend substantially or entirely behind each individual slat 409b in the ball striking face 409 of the golf club head 402. Further, as seen in FIGS. 9 and 10, according to aspects of the disclosure, piezoelectric members 420 may be configured such that the depth, or thickness, of the piezoelectric member 420 may vary with the height of the piezoelectric member 420. For example, as seen in FIGS. 9 and 10, the thickness of the piezoelectric members 420 is greater at the upper portion of each of the piezoelectric members 420 than the lower portion of each of the piezoelectric member 420. For example, the upper portion of the piezoelectric members 420 may each have a thickness in the range of 1.0-1.4 mm and the lower portion of each of the piezoelectric member 320 may have a thickness in the range of 0.5-0.7 mm. Further, as will be discussed below, the piezoelectric member 420 may include an angled configuration.

[0083] According to aspects of the disclosure, piezoelectric material may be incorporated into a golf club head still in other ways to selectively control or adjust other attributes of the golf club head. For example, according to aspects of the disclosure piezoelectric material may be configured within the golf club head to control the depth or thickness of the slats in the ball striking face of the golf club head. For example, FIGS. 11-12 illustrate an alternative embodiment of a golf club head body according to aspects of the disclosure. Specifically, FIG. 11 shows a cross-sectional view of an illustrative embodiment of the golf club head 502 according to aspects of the disclosure wherein piezoelectric members 520 are in a first position. FIG. 12 shows a cross-sectional view of the illustrative embodiment of the golf club head 502 according to aspects of the disclosure wherein piezoelectric members 520 are in a second position.

..

.

[0090] As mentioned above, while the disclosure has been described primarily in terms of use in an iron-type golf club head (including iron type-hybrid golf club heads), those skilled in the art will appreciate that aspects and features of this disclosure are not limited to use with iron-type golf club heads. For example, if desired, putter-type and/or wood-type body members may be substituted for the iron-type club head body members illustrated in FIGS. 1 and 3-12, and the same or similar features and/or structures could be included in a putter or wood structure without departing from this disclosure. For example, FIG. 14 illustrates an embodiment according to aspects of the disclosure in which a putter-type golf club head 602 is configured with a plurality of piezoelectric members 620 engaged with grooves of in the ball striking face 609 of the putter-type golf club head 602. In this way the volume of the grooves 609a can be adjusted in a manner similar to that described above with regard to the embodiment shown in FIGS. 1 and 3, 4, 5A and 5B. Hence, it is understood that any of the various features described above may be incorporated into various types of golf club heads and golf club structures including iron-type, wood-type, hybrid-type, putter-type, etc., golf club heads and golf club structures.

What do you think, will we ever see irons with piezoelectric adjustable grooves?

Comments