What Does it Take to Put the Meanest Grooves on a Club Face?

A ceramic face of course. This week Callaway had a patent issue directed to a ceramic club face. Interestingly, it originates from another application filed with a nonpublication request, which I have written about in the past here and here, leading one to believe that they did not want the competition knowing about this research project until a patent actually issued. This seems to be a trend.

The patent issued as USPN 8,105,180 titled “Iron-Type Golf Club Head with Groove Profile in Ceramic Face,” which describes the invention as:

The patent explains:

So, “micro-edges” may be the buzz word of the future!

Dave Dawsey - The Golf Invention Attorney

The patent issued as USPN 8,105,180 titled “Iron-Type Golf Club Head with Groove Profile in Ceramic Face,” which describes the invention as:

The present invention provides a method of manufacture and design such that very small detail features can be produced within the groove profile on an iron or wedge. The advantage in being able to do this is that spin will be enhanced for a variety of shot types and conditions when striking a golf ball with cover composed of a urethane-based material.

The patent explains:

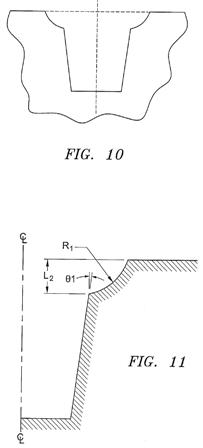

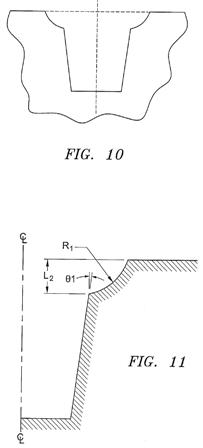

Scoreline designs generally have a cross-section geometry that includes two edges, two side walls and a bottom. The side walls are at a predetermined angle from a vertical line. Usually, each wall has more than one section and those sections are straight or curved. Alternatively, the scoreline design is a "V" shape, in which case there is no bottom other than a vertex or fillet radius.

Iron-type golf clubs having scorelines with sharp edges and relatively vertical side walls are advantageous to golfers since such sharp edged grooves allow golfers to induce higher levels of spin on a ball struck with such an iron-type golf club having sharp edged grooves. Iron-type golf clubs without sharp edged grooves or essentially vertical side walls will induce less spin when impacting a golf ball, especially higher-lofted (40 degrees +) golf clubs.

Backspin is the primary mechanism by which a golfer can control a golf ball upon landing after being struck. Backspin is especially important for short shots where proximity to the hole is of greater consequence to the golfer. High lofted clubs (50 degrees to 75 degrees) have grooves designs which are meant to interact with the surface of a golf ball at impact and remove debris from the contacting surface in order to increase friction and thereby impart more spin on the ball.

Existing materials and processes are not amenable to precision control of groove profile. Forging, casting and machining of metals all have practical limitations with regard to the feature size that can be accurately and consistently replicated in mass production. Features on the order of 0.001 inch or less within the groove (as opposed to on the land on the land between grooves) are not suitable for existing methods of manufacture using conventional materials such as stainless steel, carbon steel, titanium, aluminum and the like.

The Rules of Golf as interpreted by the United States Golf Association ("USGA") have constrained the types of scoreline patterns that may be used on golf clubs.

BRIEF SUMMARY OF THE INVENTION

The present invention seeks to accomplish a method of manufacture and design such that very small detail features can be produced within the groove profile on an iron or wedge. The advantage in being able to do this is that spin will be enhanced for a variety of shot types and conditions when striking a golf ball with cover composed of a urethane-based material.

The present invention consists of small features on the outermost edge of a groove. The features are formed in a ceramic material, most preferentially made via injection molding using a fine particulate ceramic formulation to enhance replication of fine details. The small features consist of micro-edges which will increase engagement with the ball during impact, causing increased spin on the ball. The features are precision machined in a negative tool surface and the ceramic material is formed against the tool surface.

An object of the present invention is a novel groove profile in a ceramic face insert intended to enhance backspin.

One aspect of the present invention is an iron-type golf club head having a body having a face insert composed of a ceramic material and a plurality of grooves located on the face insert having micro-edges.

So, “micro-edges” may be the buzz word of the future!

Dave Dawsey - The Golf Invention Attorney

Comments