Get Ready to Scratch Your Head and Say “Why Didn’t I Think of That”

Acushnet had an interesting patent issue today for, of all things, a golf shaft. Yes, golfers don’t normally associate the Acushnet name with golf shaft design or manufacturing, but this seems to be the case of a good idea that could not just be swept under the rug, even if it was a little outside of their core strengths. The patent is USPN 7,955,187 titled “Swingweight Adjusted Golf Club Shaft,” which describes the invention as:

The patent goes on to explain:

Did it make you scratch your head? If you can't get enough of the technical details, click the link to read the full PDF of USPN 7,955,187.

Dave Dawsey - Monitoring Golf Shaft Inventions

An improved golf club shaft and corresponding golf club is disclosed. More specifically, a golf club shaft that is capable of minimizing or eliminating swingweight variations within a golf club despite being cut down to various different lengths to accommodate the length and heads of a set of irons is disclosed. The shaft may have an internal wall profile of variable thickness to adjust for various weight and center of gravity variations of a golf club shaft as it is being cut down in length.

The patent goes on to explain:

FIELD OF THE INVENTION

The present invention relates to an improved golf club shaft. More particularly, the present invention relates to a golf club shaft for a set of clubs wherein the internal wall thicknesses of the shafts are shaped in a way that allows the golf club shafts to be cut down to an individually desirable length while minimizing or eliminating the undesirable change in the swingweight within the set of clubs.

BACKGROUND OF THE INVENTION

Golf club shafts have always been an important component of every golf club. Although many would argue that finding a correct golf club head makes the most significant impact on an individual's golf swing, finding the correct golf club shaft to go with the correct golf club head is also just as important. Currently in the art, conventional golf club shafts have been made out of various materials such as steel, metal alloy, or composites that change the various characteristics of the golf club shaft. These materials, although provide significant differences in swing characteristics of a golf club in and of themselves, are incapable of addressing the weight consistency issue within a set of golf clubs. With the development, understanding, and focus on the weight consistency issue of the golf club, it has become known that the consistency of a weight and feel of a golf club depends on more than just the weight of the shaft alone. The weight of the golf club and the way it feels when being swung are generally dependent on two factors; the actual weight of the golf club and the moment of the club around an arbitrary location; which has been called the "swingweight" of a golf club. Understanding swingweight and maintaining the same swingweight is extremely beneficial and desirable to a golfer in order to find a set of golf clubs that feels natural to the individual no matter which club is chosen.

The concept of swingweight is a well known concept within the golfing industry. Swingweight can be generically simplified as the weight relationship of a golf club about a fixed fulcrum point. More specifically, the swingweight is the measurement of a golf club's moment about the fixed fulcrum, generally placed at an arbitrary location fourteen inches away from the butt end of the grip. The swingweight is important to a golf swing because it affects how heavy the club feels during the swing regardless of its actual weight. Golf club sets that are put together without any conscious effort on maintaining the swingweight often have a major flaw in that each club feels and performs differently due to swingweight variations. This swingweight variation described above could be as little as one swingweight, but in severe situations, such variation could result in as much as four swingweights. Major differences in swingweight can significantly affect the feel of a golf club, and is often an undesirable effect. Hence, it can be seen from above that there is a need for a set of golf clubs that maintains a consistent swingweight through the various clubs.

The need for consistent swingweight is particularly prevalent within a set of irons, as they often come in a set of multiple clubs and they are expected to perform consistently within the set. In order to address the swingweight issue within a set of irons, a prevalent approach within the golf industry has been using constant weight shafts. A constant weight shaft aims to maintain the swingweight of each individual shaft within an iron set regardless of the length of the shaft. This constant weight shaft approach is generally achieved by independently manufacturing each shaft to their individual weight, length, and swingweight specifications. As a result of the individualized complicated manufacturing process, all of the shafts within a set of irons will have the same weight and swingweight regardless of the length of the shaft. This individualized and independent manufacturing process takes in consideration the weight of each of the club head, the weight of each of the grip and grip tape, the length of the shaft, and the weight of the shaft to achieve a consistent swingweight. This approach of individually manufacturing each shaft within a set of irons, although effective in maintaining swingweight, can be slow, burdensome, and expensive to manufacture.

In order to minimize production costs while still achieving constant swingweight, it is also common in the golf club industry to adapt a descending weight shaft approach as an alternative to the constant weight shaft approach. The descending weight shaft approach ignores any attempt to maintain individual shaft weight and swingweight across the set of irons. Thus, as the length of the shaft get shorter and shorter, the weight and swingweight of each shaft begin to differ across the set of clubs. Ultimately, as each individual shaft is cut down to their appropriate length, their weights are reduced by the amount of weight lost from the length reduction. In order to address the issue of the difference in swingweight, the descending weight shaft approach adjusts and modifies the weight of other components of a golf club such as the head or the grip. Because no attempt is made to adjust the weights and swingweights of the shaft themselves, all the shafts within a set of irons can be manufactured together utilizing the same manufacturing specifications, reducing the manufacturing costs. The descending weight shaft approach, although effective in reducing manufacturing costs, is ineffective in adjusting the swingweight of the individual shafts, and relies on adjustments of other components of the golf club that requires added design complexity of one or more of the other components and additional steps at the assembly stage. This additional design complexity and the additional manual assembly step can often be undesirable as it increases production cost of a golf club.

Hence, it can be seen that there is a need in the field for a golf club shaft that is capable of minimizing or eliminating the variations in the swingweight of a golf club by focusing on the shaft itself without the expensive manufacturing expenses associated with independently manufacturing each golf club shaft or expensive adjustment weights associated with final adjustments in other components or the finished product. More specifically, there is a need for a golf club shaft that can be uniformly manufactured and cut down to the desirable length to match the various length of an iron set all while minimizing or even eliminating the variations in the swingweight of the golf club shaft.

BRIEF SUMMARY OF THE INVENTION

In one aspect of the present invention is a plurality of golf clubs comprising of a first golf club containing a first shaft, and a second golf club containing a second shaft; wherein the second shaft is formed by cutting down the length of the first shaft; and wherein an internal wall profile within the first shaft allows the second golf club to have a total moment about a second fulcrum to be similar to a total moment about a first fulcrum of the first golf club.

In another aspect of the present invention is a golf club comprising of a grip connected to a first end of the golf club, a head connected to a second end of the golf club, and a shaft interposed between the head and the grip containing an internal wall profile; wherein the internal wall profile causes a moment of the shaft about a fulcrum to change from 10 gram*inchs to 50 gram*inchs for each half inch reduction in the shaft length.

In a further aspect of the present invention is a method of minimizing a swingweight variation within a plurality of golf clubs comprising of reducing the length of a first shaft by a half inch to produce a second shaft, and adjusting an internal wall profile of the first shaft; wherein the second shaft has a second shaft moment about a fulcrum that varies 10 gram*inchs to 50 gram*inchs when compared to a first moment about a fulcrum of the first shaft.

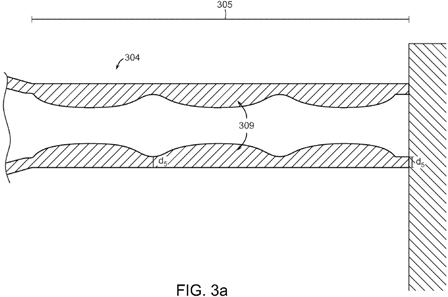

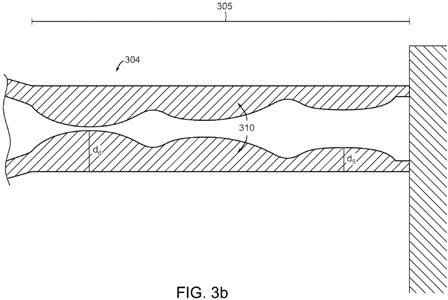

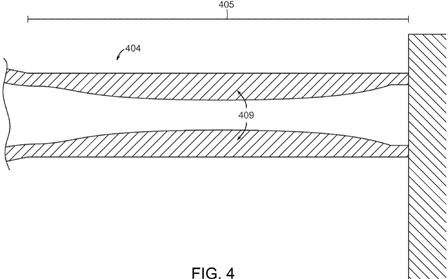

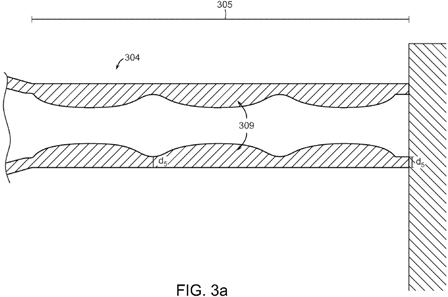

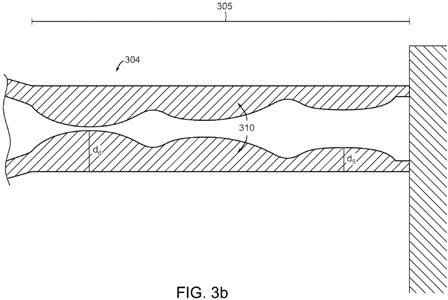

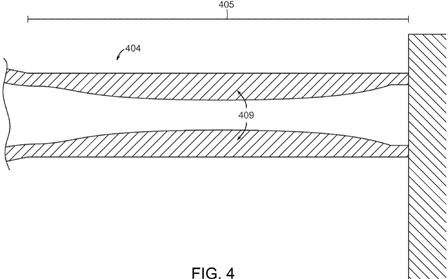

Moving on to FIG. 3a, which shows an enlarged crossed-sectional view of the parallel tip section 305 of a shaft 304 in accordance with one embodiment of the present invention. The internal wall profile may be in a sinusoidal shape across the entire range of the parallel tip section 305 to adjust for the change in the moment created by the shortening of the shaft as well as the change in head weight variation. However, the sinusoidal shape of the internal wall profile 309 could only partially extend across the range of the parallel tip section 305 without departing from the scope of the present invention. Because the ultimate swingweight variation of the golf club needed may not be a truly linear function with respect to the reduction in shaft length and the change in head weight, the internal wall profile 309 of the parallel tip section 305 may fluctuate in a sinusoidal wave shape to correspond with the swingweight variation of a golf club.

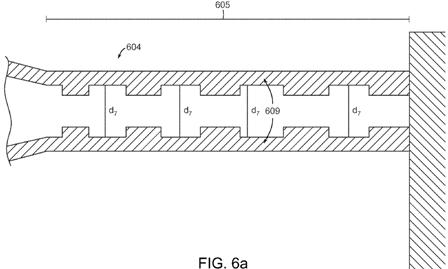

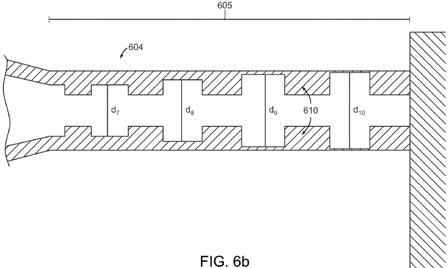

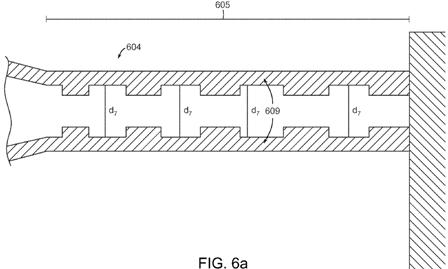

FIG. 6a shows a further alternative embodiment of the present invention wherein the parallel tip section 605 of shaft 600 has a cross-section that shows an internal wall profile 609 that is stair-stepped. Internal wall profile 609, as shown in the current alternative embodiment is in a stair-stepped shape to assist with the removal of additional weight within the internal walls of the shaft in a method that preserves a semi-parallel internal wall profile 609. In this alternative embodiment, the different arrangement and set up of golf club head, length, and shaft may require an even further different internal wall profile 609 in accordance with FIG. 6a to achieve the constant swingweight across the entire set of irons.

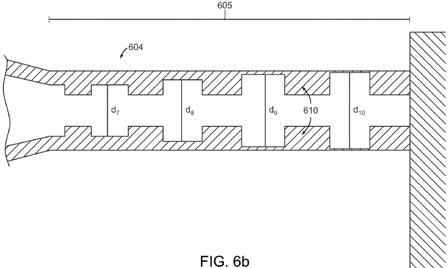

Here, in the current alternative embodiment shown in FIG. 6a, the stair stepped internal wall profile 609 may have squared edges, however, stair stepped internal wall profile 609 may have rounded edges, circular edges, or any other edge shape capable of adjusting the weight of shaft 600 to compensate for the swingweight variation all without departing from the scope of the present invention. It should be noted that each of the stair-stepped teeth in FIG. 6a all have the same thickness d.sub.7; however, each of the teeth may have a also different thickness ranging increasing from d.sub.7, d.sub.8, d.sub.9, and d.sub.10 towards the tip of the shaft as shown in FIG. 6b without departing from the scope and content of the present invention. It should be noted that although in this exemplary embodiment shown in FIG. 6b d.sub.10 may be thicker than d.sub.7, the d.sub.7 could be thicker than d.sub.10, causing an increasing internal wall thickness towards the tip of the shaft also without departing from the scope and content of the present invention.

Did it make you scratch your head? If you can't get enough of the technical details, click the link to read the full PDF of USPN 7,955,187.

Dave Dawsey - Monitoring Golf Shaft Inventions

Comments