Going Green on the Greens

I am not quite sure this invention is going to solve all of our landfill problems, but every little bit helps. A patent application published last week as US Pub. No. 20110111879 titled “Golf Club, Golf Club Head And Golf Club Grip Structures” and discloses an environmentally friendly golf club and golf grip.

I suspect Nike’s marketing department would come up with a nicer, more confidence inspiring, term than “regrind.” The application goes on to explain:

Ahh, waste product from shoe production recycled into golf products; I guess it is clear where the golf group fits in the corporate hierarchy! Kudos for at least thinking about the environment!

David Dawsey – Keeping an Eye on Golf Ball Technology

PS – click HERE to read about a biodegradable golf ball patent

Golf club, golf club head and/or golf club grip structures include portions formed of a recycled regrind material. For instance, a golf club head, such as a putter head, may include a ball striking surface at least partially formed of regrind. In some examples, the golf club grip, such as a putter grip, may be at least partially formed of the recycled regrind material. For example, the grip may have an interior grip portion formed of regrind to provide a firm, sturdy grip structure, and it may include an exterior portion wrapped around the interior grip portion and formed of a softer material. In other examples, portions of the exterior surface of the grip may be formed of regrind while other portions may be formed of a different material that may, in some examples, be softer than the regrind.

I suspect Nike’s marketing department would come up with a nicer, more confidence inspiring, term than “regrind.” The application goes on to explain:

[0009] Aspects of this invention relate to golf club, golf club head and golf club grip structures. In some examples, the golf club, golf club head and/or golf club grip may include a portion formed of a recycled regrind material. For instance, a golf club head may include a ball striking surface formed in a front face of the golf club head. In some examples, the ball striking surface (or at least a portion thereof) may be formed of a recycled regrind material.

[0010] Other aspects of this invention relate to golf club grips structures, such as putter grips. The putter grips may be formed of multiple materials, one such material being a recycled regrind material. In some arrangements, the putter may include an interior grip portion formed of a recycled regrind material and an exterior grip portion formed of a material having a lower Shore hardness value and thus having a softer feel than the interior grip portion. The exterior grip portion may form all, or substantially all, of the exterior grip surface contacted by a user during play.

.

.

.

[0039] As mentioned above, in some examples, the ball striking surface 106 may be formed of a material different from the remainder of the club head and/or may include an insert portion that may be formed of a material different from the remainder of the golf club head. For instance, the ball striking surface 106 may be formed of a material softer than the remainder of the golf club head 101 in order to provide a softer feel when using the putter and/or to provide a more true roll. In some arrangements, the ball striking surface 106 may be formed, at least in part, from a polymeric material including recycled materials, such as regrind. In some examples, the regrind may include additives used in the formation of the ball striking surface 106 that may include finely ground recycled materials. In some examples, the finely ground recycled materials may be recycled footwear materials that may be scraps, shavings, etc. generated during manufacture, defective or used articles of footwear, and the like. The additives may include leather, cotton, thermoplastics, synthetic and natural rubber, millable/partially cross-linked polyurethane, and synthetic fibers. The thermoplastics may include polyamides, polyesters and polyurethanes.

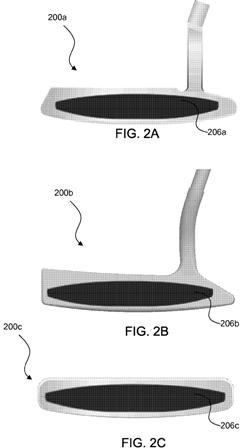

[0040] In some examples, the regrind additives may be ground to a desired particle size and added to raw material (such as new polymeric material) to form the ball striking surface 106. In other instances, the ball striking surface 106 may be formed entirely of regrind material. FIGS. 2A-2C illustrate some example golf club heads having ball striking surfaces formed at least in part from regrind materials. As shown, the golf club heads 200a-200c may vary in shape, size, configuration, etc. The ball striking surface 206a-206c may also vary in shape, size, configuration, etc. For instance, in some examples, the ball striking surface 206a-206c may comprise a majority of the front face of the golf club head 200a-200c.

Ahh, waste product from shoe production recycled into golf products; I guess it is clear where the golf group fits in the corporate hierarchy! Kudos for at least thinking about the environment!

David Dawsey – Keeping an Eye on Golf Ball Technology

PS – click HERE to read about a biodegradable golf ball patent

Comments