Golf Shoes with Retractable Spikes

It has been a while since I have covered an interesting golf shoe invention. Fortunately that changes this week with the publication of a patent application directed to a golf shoe with retractable spikes. The application published as US Pub. No. 20110047830 titled “Extendable Spikes for Shoes,” which describes the invention as:

The application explains:

Interesting concept but I am not sure anything will bring back a conventional spike construction.

David Dawsey – Watching Shoe Inventions

PS – click here to check out another interesting golf shoe invention

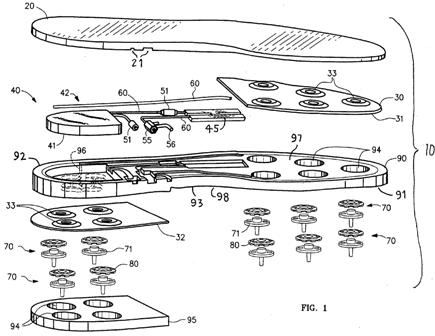

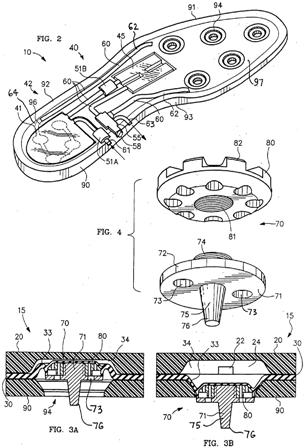

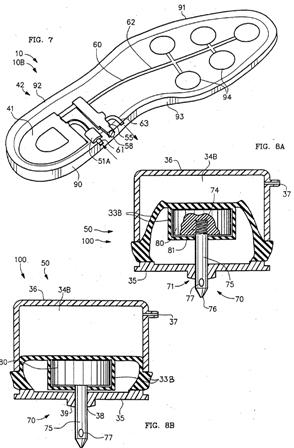

Golf shoe sole 10 having extendable spikes 71 activated by compressed air from a pump 42 located inside sole of shoe. Pump 42 is operated by weight of wearer's heel on a bladder 41 located in heel of sole and check valves 51 maintain pressure in pneumatic system. Pushbutton switch 58 selects movement of spikes 71 between retracted and extended modes.

The application explains:

[0003] Shoes with spikes or cleats are often worn for sports that require good foot traction. For example, golf players use spiked shoes for safer and more stable walking and standing on wet grass and slopes. Other conditions where shoes with retractable spikes are desirable include walking or climbing on ice or snow.

[0004] Historically, golf shoes had small metal spikes attached to the soles, such as by a threaded connection in the sole. Such spikes were durable and provided good traction, but damaged the grass of golf courses and scratched or gouged interior floors. Golf players were typically required to remove their spiked shoes before entering offices or clubhouses associated with golf courses. Most golf courses have now even banned or restricted use of metal spikes altogether.

[0005] Another type of golf spike that is less damaging to grass and floors is a blunt spike of hard plastic, which may be single- or multi-pronged. Most golf courses allow these plastic spikes to be used both on grassy fairways and on most interior surfaces.

[0006] Plastic spikes have four main disadvantages. First, they can still damage the finely groomed grass of the greens, and even leave a slight indentation.

[0007] Second, on some surfaces, plastic spikes are more slippery than most conventional shoes. For example, on a smooth or wet floor or exterior walking surface, plastic spikes can cause the wearer to slip and fall.

[0008] Third, plastic spikes are not as durable as metal ones. Although the grass of the actual golf course does not wear out plastic spikes too quickly, walking on concrete sidewalks and parking lots, for example, does shorten the life of plastic spikes greatly.

[0009] Fourth, plastic spikes collect grass and mud that reduces their ability to provide good traction with the ground.

[0010] Attempts have been made to provide non-damaging shoes for golf by including mechanisms to extend the spikes only when needed. Such mechanisms include cleats that are cranked by hand or moved by one or more levers. These retracting spikes have been found to have certain disadvantages of their own. For example, the mechanism may be prone to becoming jammed by mud or rust. The mechanism may be so difficult to operate that it is necessary to sit down to safely extend or retract the spikes. The inevitable mud and grass that creep into the moving parts cause wear and corrosion, shortening the useful life of the mechanism. Mechanical mechanisms add to the weight of the shoe and make the sole less flexible. Thus, despite attempts to create better shoes, golf players still have considerable inconvenience associated with their footwear.

[0011] There is a great need for shoes that provide traction when needed but that do not have the disadvantages of conventional golf spikes. There is further a need for spikes that do not damage golf greens or other fine-textured grass. There is a need for a golf shoe that can be worn on the course, in the clubhouse or other buildings, and for walking on sidewalks and across parking lots without excessive wear. There is a need for a durable spiked shoe that is safe to walk in on all surfaces.

[0012] In the case of retracting spikes, there is a need for a shoe that is easy enough to operate that it does not interrupt the game unduly or require the user to sit. Such a shoe would preferably be self-contained and not require the wearer to carry auxiliary equipment or replace expendable parts.

SUMMARY OF THE INVENTION

[0013] The present invention is a sole assembly for a shoe for golf or other sports, with plastic or metal spikes that may be easily extended when needed and retracted when not needed. The spikes are activated by pneumatic pressure that is generated by the wearer's own walking action. The selection mechanism for extending or retracting the spikes is a switch that can be operated with a single click.

[0014] The sole assembly includes an integral pump that selectively compresses air, powered by the wearer's weight. The compressed air expands plenum chambers that exert downward force on spike assemblies. Air pressure is maintained by check valves. The spikes protrude from apertures in the outsole then retract when air pressure is released. Mud and grass are scraped from the spikes as they retract.

[0015] Plenum chambers are embedded between midsole and outsole. Each spike is attached to a rigid ferrule, which moves like a piston inside the complementarily-shaped chamber. The ferrule is connected to, or embedded within, a flexible plenum membrane. The chamber walls support the plenum membrane such that over-distortion of the material does not occur, thereby prevent cracking of the rubber from stress.

[0016] The plenum membranes are biased in an upward position. When air pressure is released by actuating the switch, membranes, ferrules, and attached spikes retract into the sole.

[0017] All components of the sole assembly, including valves, may be constructed from synthetic polymeric materials to avoid corrosion and any need for external lubrication. The pump device consists of a compressible bladder and an optional pressure reservoir, both made of resilient rubber. They are designed to flex with the sole assembly and not create discomfort to the wearer. All materials are selected for durability and reliability of the sole assembly.

Interesting concept but I am not sure anything will bring back a conventional spike construction.

David Dawsey – Watching Shoe Inventions

PS – click here to check out another interesting golf shoe invention

Comments