Ahh, Finally a Self-Cleaning Golf Club (by Nike)

This interesting Nike invention is disclosed in a patent application that was published today as US Pub. No. 20100261538 titled “Golf Club Having Hydrophobic And Hydrophilic Portions,” which describes the invention as:

A golf club or component thereof has a surface, wherein at least one area of the surface has a level of hydrophilicity which is less than the level of hydrophilicity in at least one surrounding portion, causing moisture to be preferentially attracted to the surrounding portion. In one aspect, the surface is a striking face and the surrounding portion is one or more grooves formed in the striking face. In another aspect, the surface is a grip and the surrounding portion is one or more channels formed in the grip. In some examples, hydrophobic or superhydrophobic surfaces on golf club components repel water and, in some instances, also offer self-cleaning functionality.

OK, that sound interesting, but keep reading to fully wrap your head around this.

[0004] The grooves on the face of a golf club can have a significant effect on ball flight. Different groove geometries can lead to differences in the amount of spin, velocity, and trajectory of the ball after impact with the face. The presence of dirt, grass, sand, and/or water on the club face can interfere with the intended impact between the ball and club face. Deeper and/or wider grooves can accommodate greater amounts of foreign matter, e.g., water, grass, etc. The grooves can keep foreign matter away from the face of the golf club and allow the face to interact more cleanly with the ball on impact. However, rules governing golf club design have limited the ability to systematically improve groove design.

SUMMARY

[0005] The following presents a general summary of aspects of the invention in order to provide a basic understanding of the invention and various features of it. This summary is not intended to limit the scope of the invention in any way, but it simply provides a general overview and context for the more detailed description that follows.

[0006] Aspects of this invention are directed to golf clubs or individual components thereof, such as golf club heads, grips, and the like. In one aspect, a golf club or component thereof has a surface wherein at least one area of the surface has a level of hydrophilicity which is less than the level of hydrophilicity in at least one surrounding portion. The higher level of hydrophilicity in the surrounding portion(s) causes moisture to be preferentially attracted to the surrounding portion(s), e.g., away from the surface. In one aspect, the surface is a striking face and the surrounding portion comprises one or more grooves in the striking face. In another aspect, the surface is a grip and the surrounding portion comprises one or more channels formed in or surrounding to the grip. In yet another aspect, the surface is a portion of a striking face, and the surrounding portion comprises multiple surrounding areas with varying levels of hydrophilicity.

.

.

.

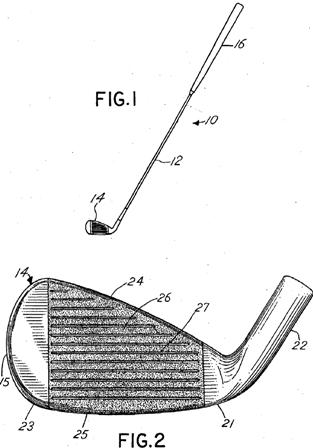

[0017] According to one aspect, one or more surfaces of the golf club 10 has a level of hydrophilicity which is less than the level of hydrophilicity in one or more surrounding portions. As a result, moisture is attracted to the surrounding portions, e.g., away from the surface of lower hydrophilicity. The surrounding portion or portions may be in grooves, channels, recessed portions, etc. interspersed with the surface. For example, in the golf club head shown in FIG. 2, the surface having a lower level of hydrophilicity may be the striking face 26, and the surrounding portions having a higher level of hydrophilicity may be the horizontal grooves 27 traversing the striking face 26. It should be understood that not all surrounding portions need have a relatively higher level of hydrophilicity, for example one or more surrounding portions may have a level of hydrophilicity which is the same as that of the surface.

..

.

[0019] As another example of surrounding portions being interspersed with a surface, the surface may have small pores that are capable of drawing moisture. The pores may be provided, for example, by using a metal foam having small open-celled porosity. The inside surfaces of the pores may be coated with a hydrophilic compound to promote a "wicking" action of moisture away from the surface. Open-celled metal foams, often constructed from aluminum, have a structure similar to open-celled polyurethane foams and have been used in aerospace and other industries.

[0020] Instead of being interspersed with the surface, the portion of greater hydrophilicity may be otherwise located in close proximity to the surface. As described herein, the surrounding portion of greater hydrophilicity is in sufficiently close proximity to enable moisture present on the surface to be attracted (at least to some extent) to the hydrophilic portion. For example, a portion of greater hydrophilicity may surround or partially surround the perimeter of the striking face 26 in the golf club head shown in FIG. 2. Although the portion of greater hydrophilicity is illustrated in the drawings in grooves or recessed areas, it should be understood that the invention is not so limited. The portion(s) of greater hydrophilicity may be coplanar or otherwise coextensive with the surface of lower hydrophilicity, or in some cases may project from the surface. As another example, portion(s) of greater hydrophilicity may be on inside surface(s) of a head cover. This way, moisture present on the club head or portion(s) thereof may be drawn toward the portion(s) of greater hydrophilicity on the inside surface(s) of the head cover to facilitate drying of the club head.

[0021] While the hydrophilic surface has been described above in conjunction with a striking face 26 of a golf club 10, it should be understood that one or more portions of relatively high hydrophilicity may be provided in one or more other regions of a golf club where it may be desirable to preferentially attract moisture away from a surface. For example, as in the embodiment shown in FIG. 3, the grip member 16 may be provided with a plurality of fine grooves 18 that have a greater level of hydrophilicity than that of the outer surface of the grip member 16. This way, moisture is attracted into the fine grooves 18 and away from the outer surface of the grip member 16, making it less likely that the grip member 16 will slip in a golfer's hands. Instead of providing grooves 18, a hydrophilic portion may be provided in the form of a band or bands surrounding the shaft 12 and/or grip member 16. As another example, the lower leading edge of a golf club face may have a hydrophobic portion. This may be particularly beneficial for clubs, such as wedges, that are more likely to be used for ball striking in rough, wet grass conditions. It also may be beneficial to have a strongly hydrophobic surface on the striking face of a putter to draw moisture away, thereby helping to improve putting accuracy. As yet another example, the upper surface of a driver or fairway metal type club may have a hydrophobic surface for repelling moisture for aesthetic purposes.

[0022] A variety of techniques may be used to create different levels of hydrophilicity between the surface and the surrounding portion(s), so that moisture is preferentially attracted to the surrounding portion(s) of higher hydrophilicity. In one aspect, materials having different levels of hydrophilicity may be used to construct the surface and the surrounding portion(s). For example, the striking face 26 may be constructed of metal or other conventional materials, and the inside surfaces of the grooves 27 may be coated with a material, such as a metal or polymer which has a greater level of hydrophilicity than that of the striking face 26. Alternatively or additionally, the striking face 26 may be constructed from or coated with a hydrophobic material, rendering the grooves 27 more hydrophilic than the striking face 26. Polymers such as polypropylene and co-polyesters generally have a low surface-attractive force for water. Other non-limiting examples of hydrophobic materials include waxes, fluorinated polymers such as polytetrafluoroethylene, and the like. Hydrophobic and superhydrophobic coatings are commercially available, non-limiting examples of which include DURALON (.theta.=118.degree., available from Cotec) and Fluorothane WX 2100 (.theta.>150.degree.) and Fluorothane GE (.theta.>115.degree., both available from Cytonix).

Amazing! How do they come up with these ideas?

David Dawsey – The IP Golf Guy

PS – click HERE to read more posts about inventions and irons

Comments