The Week of Karsten Solheim - Day 3 - The Lone Golf Ball Patent

Over the past few days we have examined Karsten Solheim’s non-golf related patents, as well as his golf tool related patents; well, there is one other unusual invention and patent that most people would not typically associate with Karsten and the PING brand.... a golf ball patent.

Karsten’s one and only golf ball patent is USPN 4653758, which is appropriately titled “golf ball” and issued in 1987. The patent explains:

It seems that this man of many talents also knew a thing or two about aerodynamics and golf ball manufacturing. Stay tuned, posts later this week will cover Karsten Solheim’s inventions directed to grips, woods, irons, and, of course, putters.

Dave Dawsey - Monitoring the Golf Ball IP

Karsten’s one and only golf ball patent is USPN 4653758, which is appropriately titled “golf ball” and issued in 1987. The patent explains:

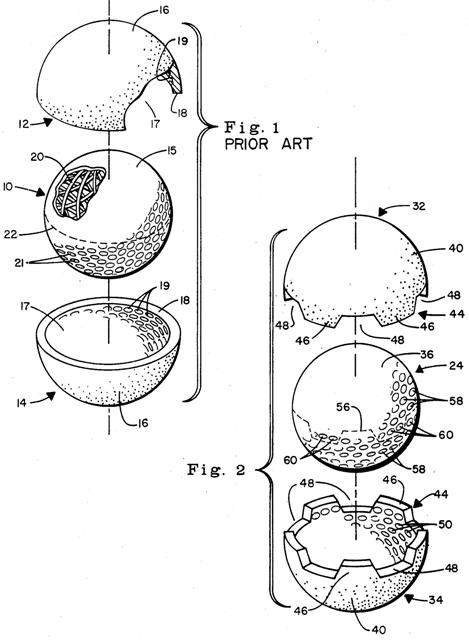

The usual golf ball manufacturing techniques includes the winding of an elastomeric band about a spherical elastomeric core to form the body of the golf ball. Another technique being employed by some manufacturers is to form a one-piece spherical body of a suitable elastomeric material. In either case, the golf ball body is moldingly encapsulated in a cover of synthetic resin, or plastic, such as the material known in the art as Surlyn which is a registered trademark of the Dupont Co.

The cover molding operation is accomplished by using a pair of hemispherical molds each of which has an array of protrusions machined or otherwise provided in its cavity, and those protrusions form the dimple pattern on the periphery of the golf ball during the cover molding operation. A pair of hemispherical cover blanks, of the above mentioned synthetic resin material, are placed in a diametrically opposed position on the golf ball body, and the body with the cover blanks thereon are placed in the hemispherical molds, and then subjected to a molding operation. The combination of heat and pressure applied during the molding operation results in the cover blanks being fused to the golf ball body and to each other to form a unitary one-piece cover structure which encapsulates the golf ball body. In addition, the cover blanks are simultaneously molded into conformity with the interior configuration of the hemispherical molds which results in the formation of the dimple pattern on the periphery of the golf ball cover.

As in all molding operations, when the golf ball is removed from the hemispherical molds subsequent to the molding operation, it will have molding flash, and possibly other projecting surface imperfections thereon. The molding flash will be located at the fused circular junction of the cover blanks and the parting line of the hemispherical molds. The molding flash will therefore be on a great circle of the spherical golf ball, and that great circle is sometimes referred to in the golf ball art as the "equator" of the golf ball.

The molding flash and possible other projecting surface imperfections, needs to be removed and this is normally accomplished by a grinding operation. Due to the need for grinding, the molding operation must be accomplished in such a manner that the molding flash is located solely on the surface of the golf ball and does not extend into any of the dimples. In other words, a grinding operation cannot reach into the dimples of the golf ball to remove the molding flash without ruining the golf ball cover.

Therefore, the prior art hemispherical molds are fabricated so that the protrusions formed therein are set back from the circular rims, or mouths of their cavities. This results in the equator of a molded golf ball being devoid of dimples and the molding flash being located solely on the smooth surface provided at the equator of the golf ball.

In addition to facilitating the grinding-off of molding flash, the protrusions formed in the cavities of the hemispherical molds are set back from the circular mouths of the molds to facilitate removal of the molds from the molded golf ball after completion of the molding operation. If projections were formed at the circular mouths of the molds, they would extend into dimples formed at the equator of the golf ball, and pulling the molds off of the golf ball in directions perpendicular to the plane of the equator would be difficult, if not impossible.

As is well known, the dimple pattern of a golf ball is a critical factor insofar as the flight characteristics of the ball are concerned. The dimples determine the lift and flight stability of the golf ball. When a golf ball is struck properly, it will spin about a horizontal axis and the air friction and air currents produced by the dimples of the spinning ball will act on the ball and thus determine the lift and flight stability thereof.

In order for a golf ball to achieve optimum flight stability, its dimples must be disposed symmetrically relative to a plane that is perpendicular to its horizontal axis of rotation. Any deviation from such symmetry will result in unequal air friction and air currents acting on the ball thus causing it to deviate from the intended flight path.

In that prior art golf balls are manufactured with a smooth surface along a great circle, or equator of the ball, the only possible symmetrical arrangement of the dimple patterns that can be provided on these balls is relative to the equator. In other words, the dimple arrays on the hemispherical portions on opposite sides of the equator can be symmetrically arranged with respect to each other. If such symmetry is achieved during manufacturing of a prior art golf ball, the dimple arrays will, of course, be symmetrical relative to the equator and possibly relative to a great circle which is perpendicular to the equator. The dimple pattern cannot possible be symmetrical relative to any other great circle on the spherical surface of the prior art golf balls in that the smooth surface of the equator will interrupt and thus destroy the symmetry.

Therefore, there are only two ways that a spinning golf ball of this prior art type of golf ball can possibly achieve optimum flight stability. The first condition wherein optimum flight stability could possibly be achieved is when the equator lies in the plane which is perpendicular to the horizontal axis of rotation, with the second being when the equator is oriented so that the horizontal axis of rotation passes diametrically through the equator.

Therefore, since the prior art golf balls are manufactured with a smooth surface equator, they are limited as to the symmetry of their dimple patterns and as a result, a very low percentage of golf ball flights will achieve optimum flight stability. In addition, in that the prior art golf balls are made by fusing the two hemispherical cover blanks along a great circle, that circular fused junction is a weak spot in the cover of such golf balls.

Therefore, a need exists for a new and improved golf ball, with a method and molds for making same, which overcome some of the problems and shortcomings of the prior art.

SUMMARY OF THE INVENTION

In accordance with the present invention, a new and improved golf ball is disclosed which is fabricated by a new method that includes the use of especially configured molds so that the golf ball is formed without a smooth surface lying on a great circle, or equator, as is the case in prior art golf balls. By eliminating the need for a smooth surface equator, the dimple pattern on the golf ball of the present invention need not be interrupted by the equator and therefore can be arranged so as to be symmetrical with respect to a plurality of different great circles of the golf ball and thereby significantly increase the chances of achieving flight stability of the ball.

The golf ball of the present invention is fabricated in the same basic manner as the hereinbefore described prior art technique. The golf ball body, either a one piece or a two piece structure, is placed in the above mentioned special molds with a pair of hemispherical cover blanks positioned on diametrically opposed sides of the golf ball body. Under the influence of the relatively high temperatures and pressures applied during the molding operation, the two cover blanks are fused into a unitary one-piece cover which conforms to the interior configuration of the molds and is encapsulatingly fused to the golf ball body.

The fused junction of the cover blanks of the prior art golf ball is, as hereinbefore described, of circular configuration which lies on a great circle of the golf ball. The fused junction of the golf ball of the present invention circumscribes the golf ball but is of a wave form configuration as opposed to circular. In other words, the fused wave form junction is alternately disposed on one side of a great circle and the other and thus repeatedly crosses but never extends on that great circle.

To achieve the wave form fused junction of the golf ball of the present invention, the generally hemispherical molds are formed with matching wave form mouths or rims which surround the openings of the cavities thereof. The wave form mouths, or rims, of the molds may be of substantially square wave, undulatory or equivalent form to provide an endless alternating series of land areas and recessed areas. When used to moldingly form the cover of the golf ball, the molds are aligningly positioned so that the land areas of one mold are nestingly disposed in the recessed areas of the other mold.

In that the fused junction of the golf ball of the present invention is of wave form configuration, a considerably larger extent of the fused surfaces of the cover blanks is provided which increases the strength of the fused junction in comparison to the circular junction of the prior art.

The special molds are further provided with protrusions in the cavities thereof which form the dimples on the golf ball cover during the molding operation. Due to the wave form configuration being formed on the mouths of the molds, protrusions may be provided on the inwardly facing surfaces of the land areas, and those protrusions result in dimples being formed in the fused junction area of the golf ball of the present invention where the prior art golf balls are devoid of dimples.

Since the dimples formed in the fused junction area of the golf ball are formed by protrusions located on the inner surfaces of the lands of the molds, the molds can be removed from a molded golf ball due to the land areas being radially deflected during removal.

In that the smooth surface equator of the prior art has been eliminated in the manner discussed above, the dimple pattern on the golf ball of the present invention can be arranged in an uninterrupted manner which heretofore could not be accomplished. As a result of this, the golf ball of this invention can be provided with virtually any dimple pattern,

For example, dimple pattern of the golf ball of the present invention may be arranged so that the dimples subdivide the spherical surface of the ball into a geodesic spherical configuration derived from a geometric solid known as a regular polygon, with the regular polygon being a regular dodechedron, a regular icosahedron or the like. To more fully appreciate the advantages of such dimple patterns, the following explanation is presented. A regular icosahedron is a solid whose surface is made up of twenty equilateral triangles. Therefore, a geodesic sphere derived from such a solid has its surface subdivided into twenty equilateral spherical triangles. The dimple pattern of this example is arranged on the surface of the golf ball so as to define the twenty equilateral spherical triangles and provide an identical number and array of dimples within the included area of each of those triangles. With the dimple pattern arranged in this manner, the dimple pattern is perfectly symmetrical with respect to fifteen different great circles of the spherical golf ball, and is very close, but not quite perfectly symmetrical, with respect to an additional multiplicity of great circles.

Therefore, the golf ball of the present invention with a dimple pattern arranged in that manner will significantly increase the chances of achieving flight stability in comparison to prior art golf balls. And, in addition, significantly reduces deviation of a golf ball from the intended flight path when none of the fifteen different great circles of perfect symmetry happens to lie in a plane that is perpendicular to the horizontal axis of rotation of a spinning golf ball.

It seems that this man of many talents also knew a thing or two about aerodynamics and golf ball manufacturing. Stay tuned, posts later this week will cover Karsten Solheim’s inventions directed to grips, woods, irons, and, of course, putters.

Dave Dawsey - Monitoring the Golf Ball IP

Comments