Need Something Ridiculously Simple to Sound Incredibly Advanced? Hire a Patent Attorney

Familiar with the TaylorMade Targa Tour Glove and its “patent pending micro-perforated leather construction to increase airflow throughout the hand and allow for 360 degree ventilation?” Nice looking glove, right. Check out the link, and these figures:

A patent application recently published directed to this perforated glove construction. The application published as US Pub. No. 20090313742 titled “Golf Glove Having Perforations,” which explains the breakthrough as:

For crying out loud, it’s a golf glove with needle holes throughout! Yes, funny ha-ha; but seriously, I truly believe that creating a well drafted patent application on a simple invention in a unique manner so that it has a shot at patentability is one of the most difficult documents to create. Unfortunately, no one will believe that statement unless they have actually done it. Oh well, such is life.

Dave Dawsey - Keeping an Eye on Golf Glove Inventions

PS – Click HERE to read about Acushnet’s patent application directed to an acupuncture golf glove.

PPS – Check out other golf glove related posts HERE

A patent application recently published directed to this perforated glove construction. The application published as US Pub. No. 20090313742 titled “Golf Glove Having Perforations,” which explains the breakthrough as:

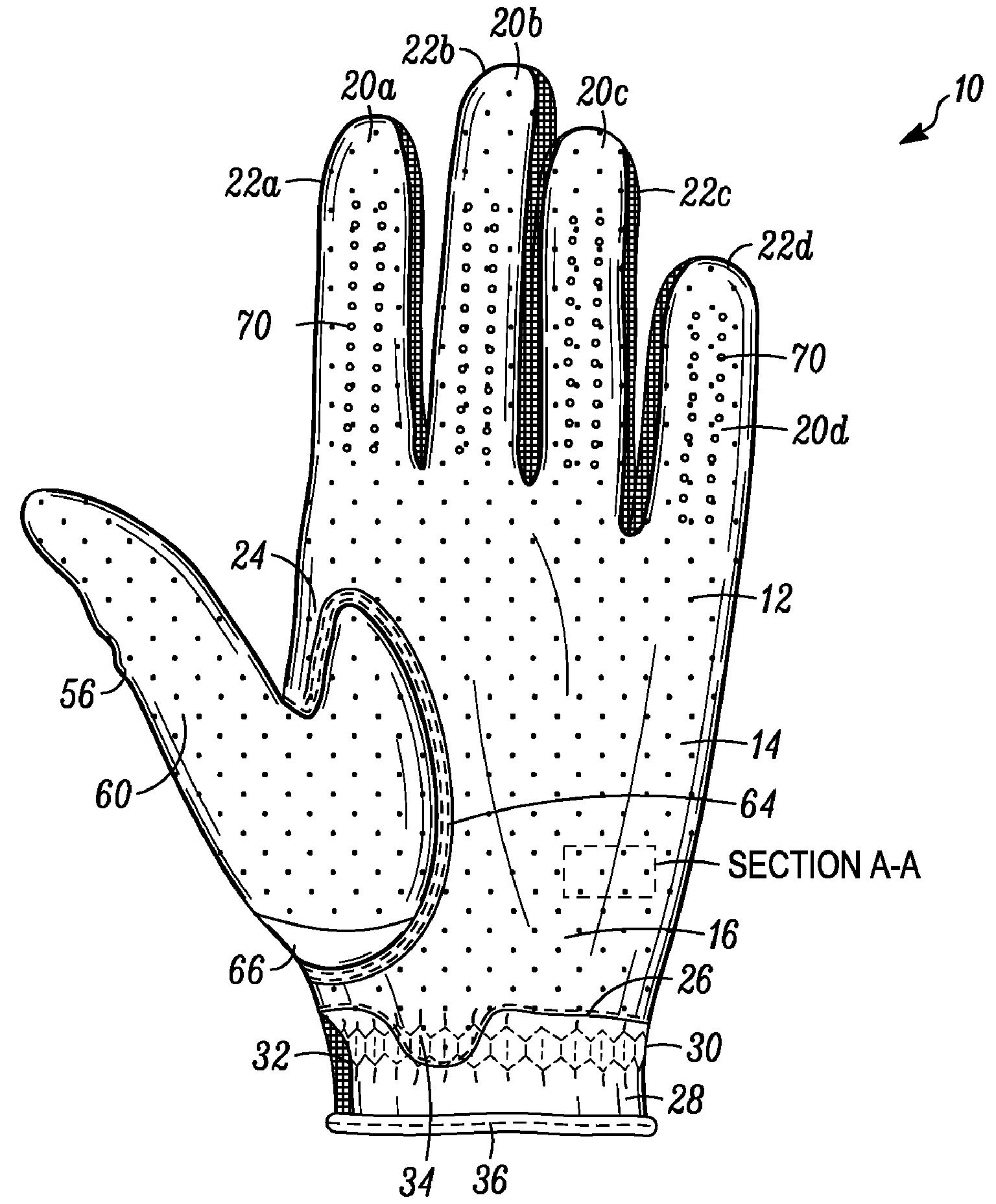

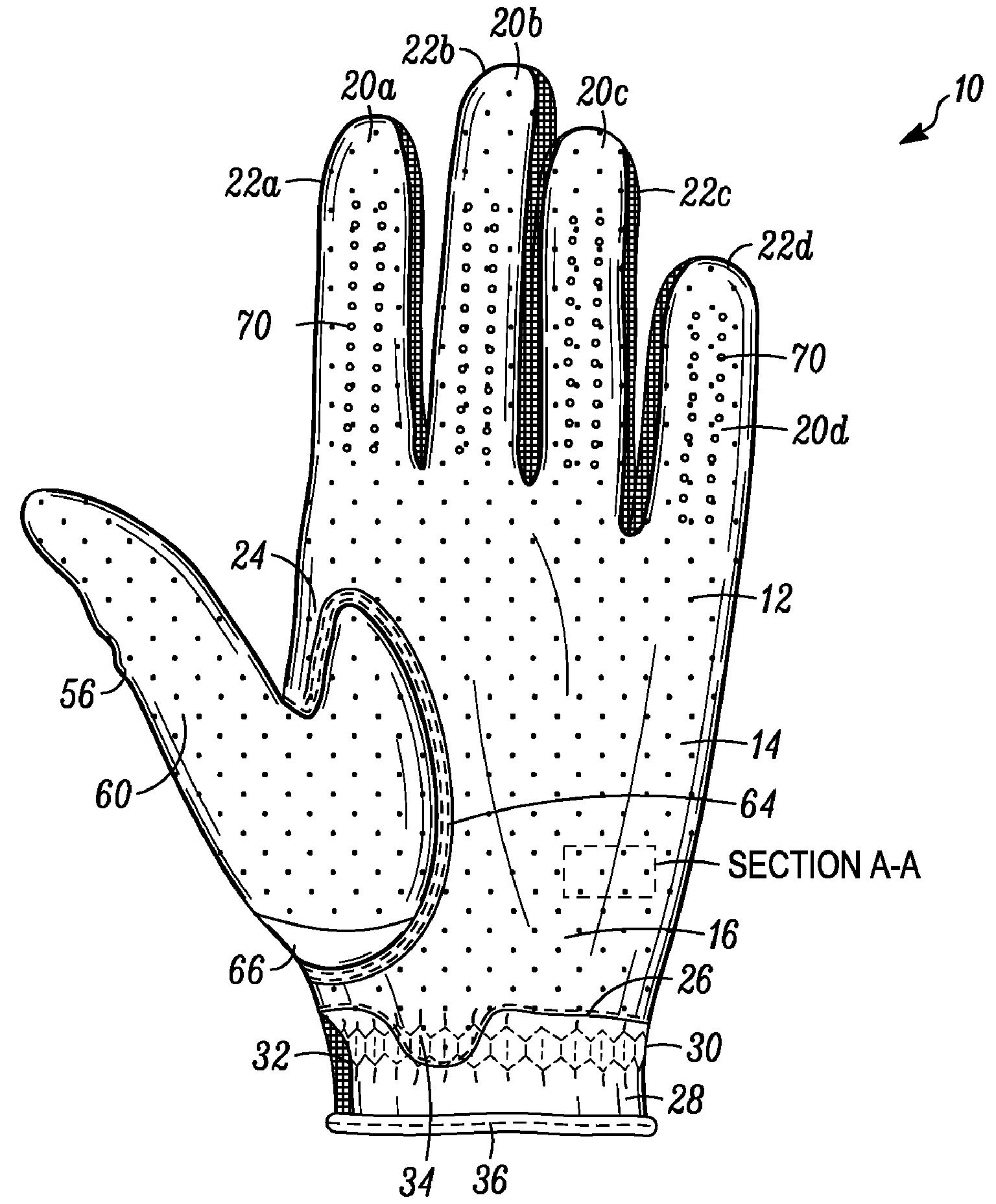

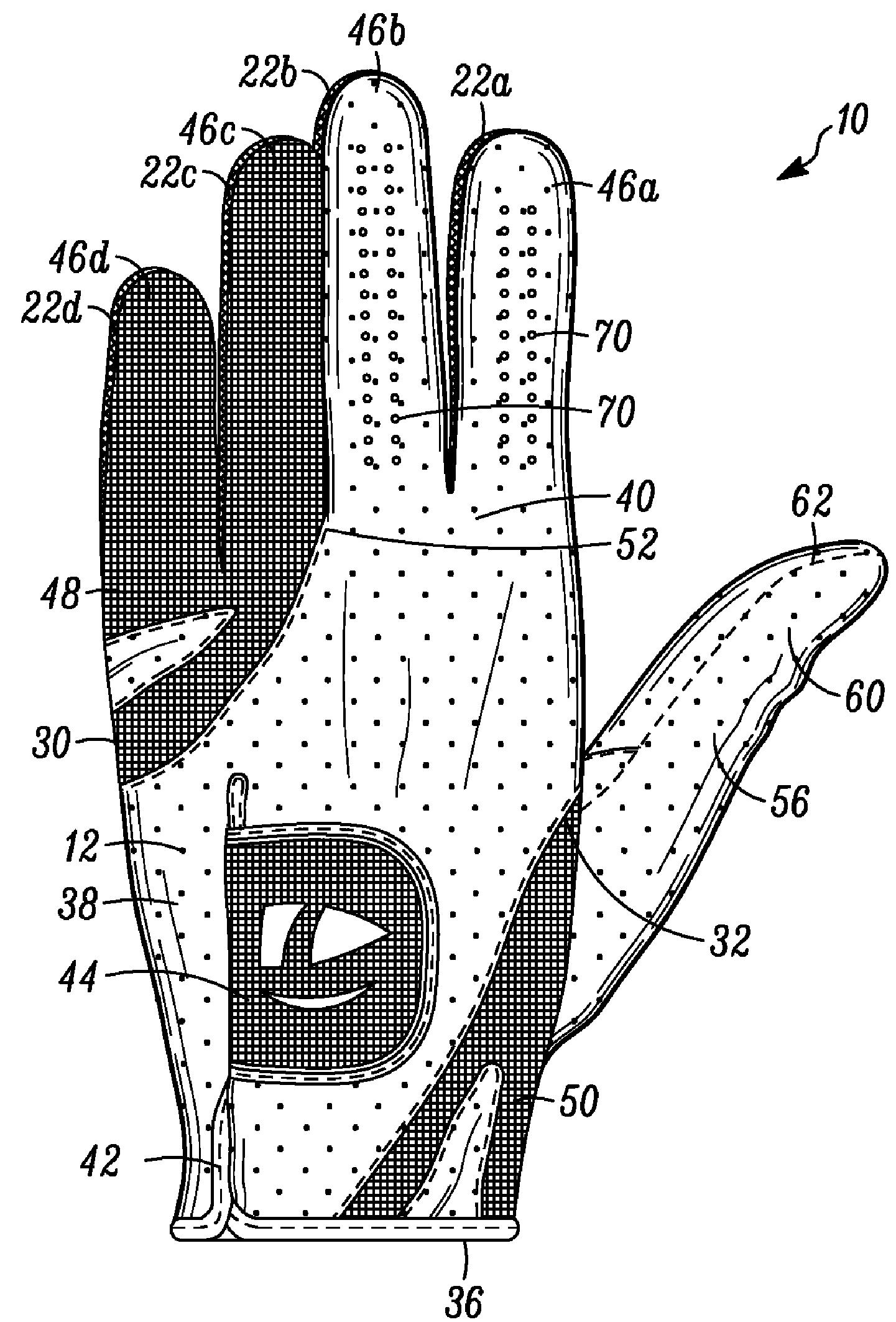

[0019] Referring now to the drawings, and particularly to FIG. 1, there is shown a golf glove 10. The glove includes sections made of elastic material and inelastic material, strategically positioned about the glove to enhance fit and performance. Sections of the inelastic material define a plurality of perforations 12 spaced substantially throughout the glove. The perforations enhance dissipation of heat and moisture out of the glove. In addition, the spacing and alignment of the perforations facilities the glove's durability, so that tears do not spread unduly.

[0020] With reference now to FIG. 1, a palmar side 14 of the glove 10 is shown, having a palmar section 16 defining a palm region 18 and palmar sides (20a, 20b, 20c, 20d) of the finger portions (22a, 22b, 22c, 22d). The palmer section is formed of inelastic material having perforations 12, as discussed above. The palmar section includes a thumb extension 24 disposed along a thumb web region. The palmer section is attached along its proximal end 26 to a wrist section 28 formed of padded elastic material. The wrist section has a width of about 8 mm, extending from an ulnar stitch line 30 to a radial side stitch line 32.

[0021] The palmer section 16 includes a proximal extension 34. The proximal extension is strategically positioned enhance durability and aid the user in applying the glove. The proximal extension is positioned adjacent to the thumb pad and is directed to a wrist edge 36 of the glove. In use, the user can grasp the glove with his second hand at the proximal extension as he inserts his hand in the glove.

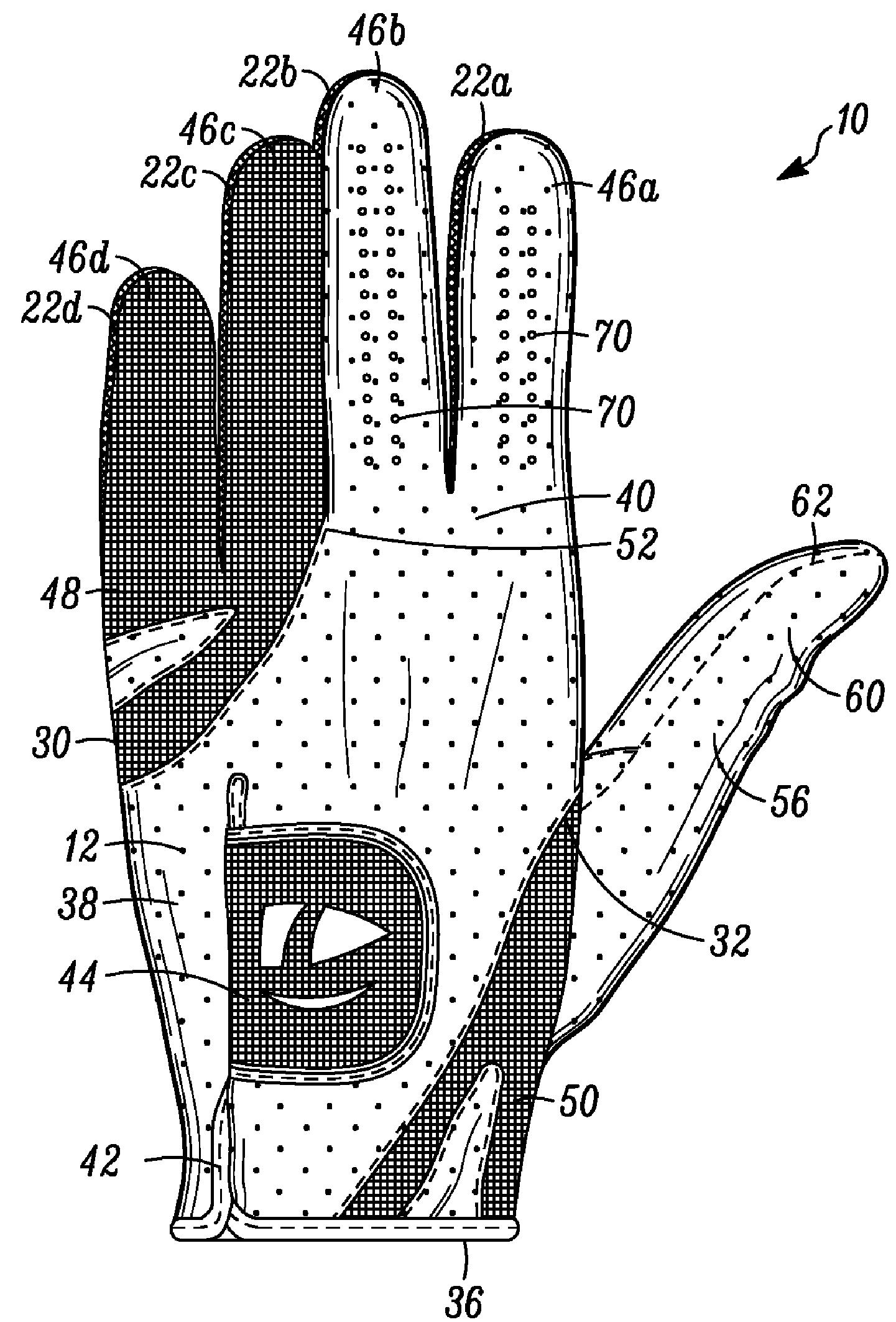

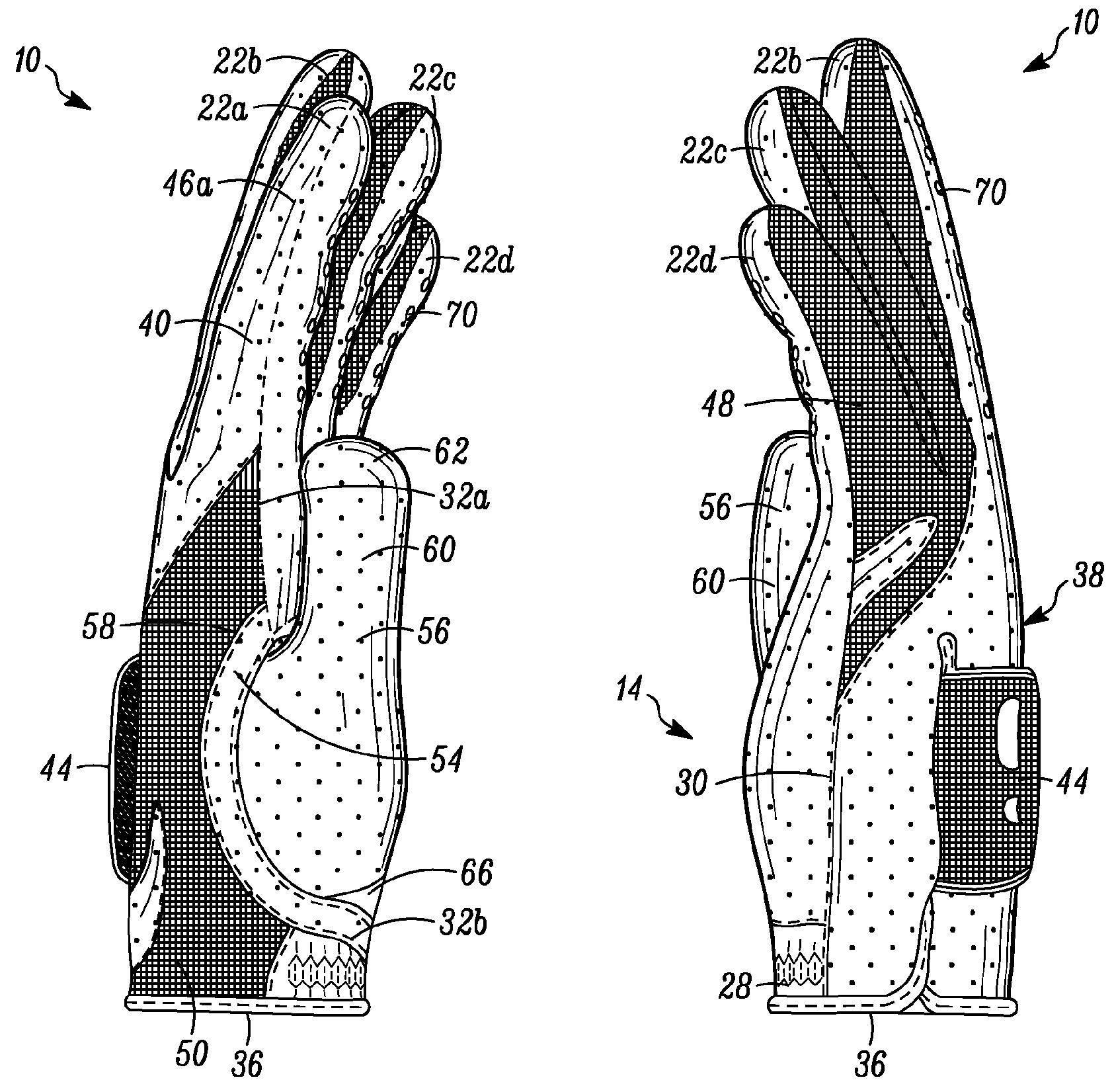

[0022] With reference to FIG. 2, a dorsal side 38 of the glove is shown, having a dorsal section 40 and defining a slit 42. The slit extends from the wrist edge towards the knuckle region of the glove to aid the user in applying the glove. The dorsal side further includes a strap 44 that fastens across the slit to secure the glove in place when worn. In the exemplary embodiment, hook and loop material is used, however, other fastening approaches can be used, as is known in the art.

[0023] The dorsal section 40 formed of inelastic material (e.g., leather, synthetic leather and other inelastic materials known in the art) having perforations 12, as discussed above. The dorsal section covers a substantial portion of the dorsal side of the hand, including the dorsal sides (46a, 46b) of the index and middle finger portions (22a, 22b).

[0024] The dorsal side 38 further includes two sections of elastic material, an ulnar section 48, and a radial section 50. The ulnar section 48 covers the dorsal sides of the little finger and the ring finger portions (46c, 46d). The ulnar 48 section is coupled to the dorsal section 40 by an arcuate stitch line 52 that extends from a web region between the middle finger section 22b and the ring finger section 22c to the ulnar side stitch line 30. The radial section 50 extends from a wrist end 36 of the glove generally towards the index finger section 22a. More particularly, the radial section terminates along the radial side edge 32 below the index finger section.

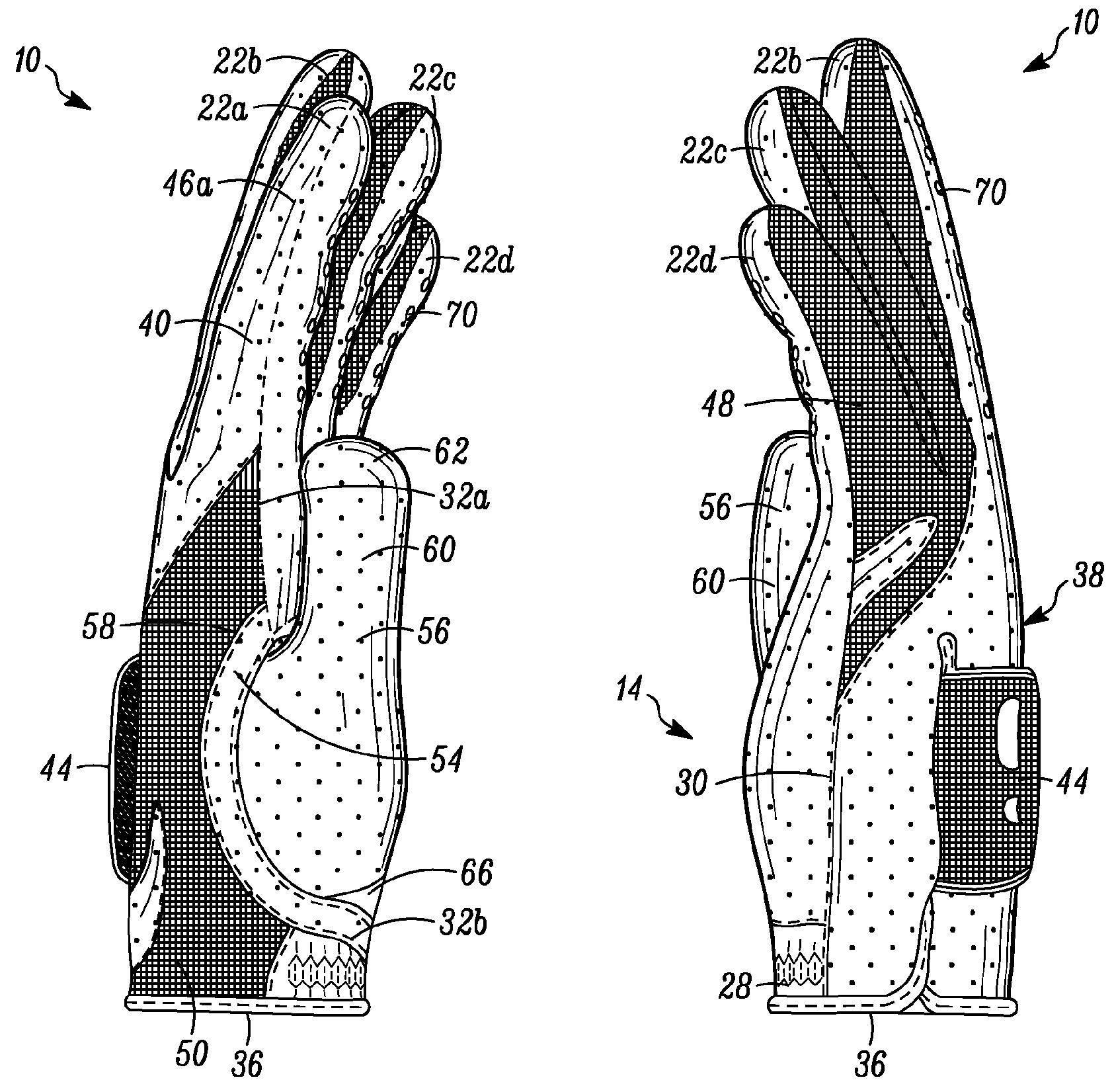

[0025] With reference to FIG. 3, the dorsal side 38 further includes a radial-edge section 54 of inelastic material disposed between the radial section 50 and a thumb portion 56 of the glove. The radial-edge section has an arcuate shape as it circumscribes the base of the thumb, providing stable support thereto. In the exemplary embodiment, the radial-edge portion extends from (a) a web region 58 of the glove between the index finger and the thumb of the user to (b) the radial side edge 32b proximal of the thumb.

[0026] As best seen in FIGS. 3-5, the palmar side 14 and the dorsal side 38 are attached to each other along the ulnar side stitch line 30 and the radial side stitch lines 32a, b. The ulnar side stitch line extend substantially the entire length of the glove 10 from the wrist edge 36 to the tip of the little finger portion 22d. The radial side stitch line 32a extends along the index finger portion 22a. The radial stitch line 32b disposed in the wrist portion between the wrist end 36 and the thumb portion 56.

[0027] The thumb portion 56 includes a section 60 is primarily formed of a single piece of inelastic material, e.g., leather or simulated leather. A stitch line 62 extends across the distal end of the thumb and proximally down a side of the thumb. The thumb section 58 is attached to the palmar section 16 via a stitch line 64. The thumb section includes a plurality of perforations 12, as discussed above.

[0028] The thumb portion 56 further includes a thumb base portion 66 is attached to a proximal end of the thumb section between the thumb section and the remaining dorsal side of the glove. The thumb base portion is formed of elastic material, such as Lycra material or Spandex material available from E. I. du Pont de Nemours and Company, or other material having elastic properties. In the exemplary embodiment, the thumb base portion is attached to the thumb section along stitch line 68.

[0029] The palmar side (20a-d) of the four fingers and the dorsal side (44a, b) of the index and middle fingers both define finger perforations 70. The finger perforations are disposed distal of the knuckle region of the glove. In the exemplary embodiment, the finger perforations are about 2.5 mm in diameter. In other embodiments, finger perforations can be excluded.

[0030] In an exemplary method of manufacture, the perforations are formed on the inelastic material (e.g., leather, synthetic leather and other inelastic materials known in the art) prior to assembly of the glove and can be formed on the inelastic material prior to cutting sections for use in the glove. The inelastic material is passed between a first roller having a plurality of needles and a support structure. In the exemplary embodiment, the needles are pointed, closed end needles. Thus, the needles tend not to remove much of the inelastic material; rather, they tend to cause punctures in the materials. In other embodiments, the needles include an open bore, which tend to remove prescribed amounts of material.

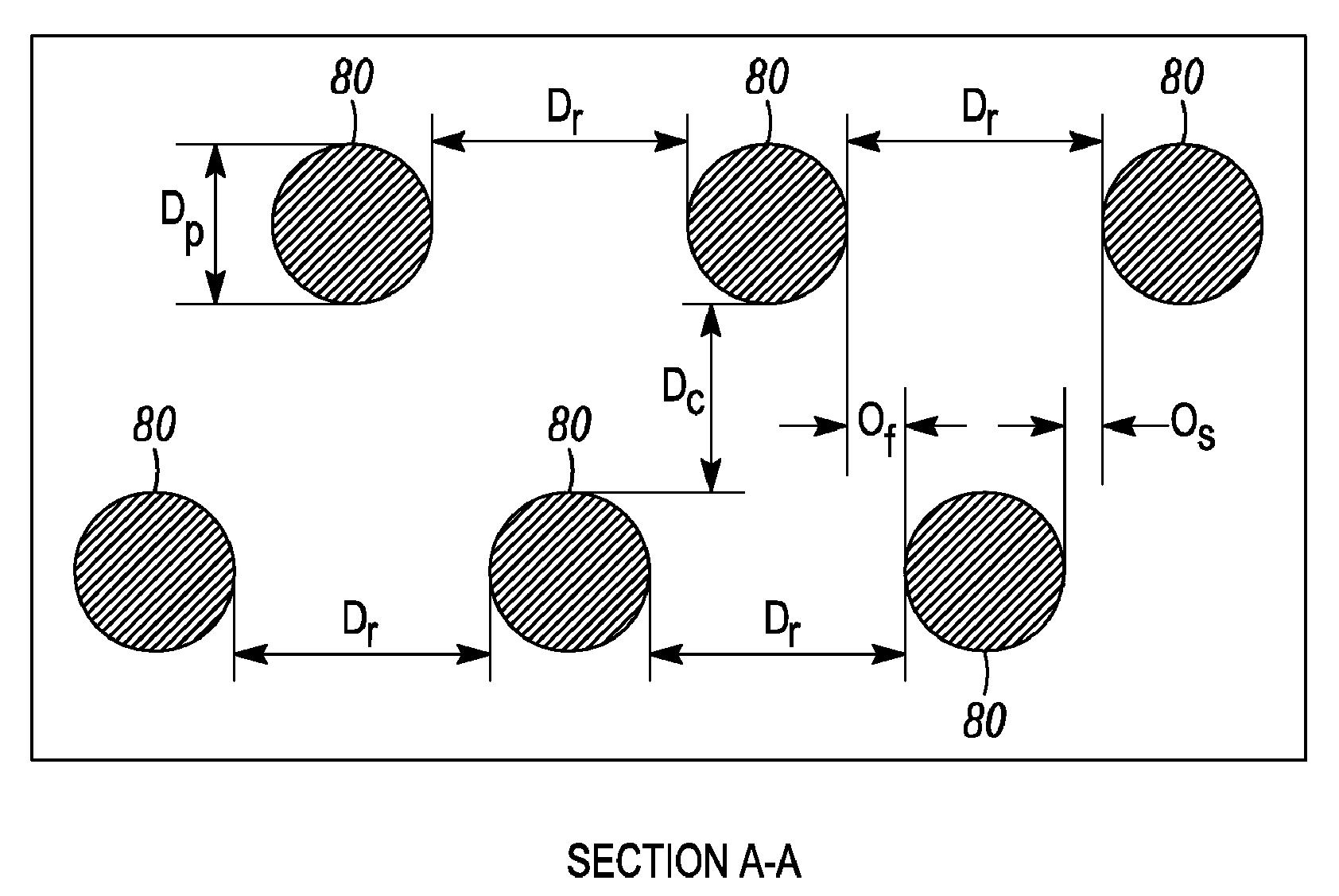

[0031] With reference now to FIG. 7, the needles 80 are spaced to form perforations in a manner to facilitate comfort and durability. The spacing and alignment of the perforations facilities the glove's durability, so that tears do not spread unduly. The needles are less than about 2 mm in diameter and are preferably between about 1.5 mm and 0.4 mm, and more preferably between about 1.3 mm and 0.8 mm. In the exemplary embodiment, the needles have a diameter (Dp) of about 1.06 mm. The resulting perforations facilitate comfort of the glove, as opposed to larger perforations, which would be distracting and inhibit feel of the club grip in the user's hand.

[0032] In exemplary embodiment, the needles 80 are vertically and horizontally aligned, with a slight offset. Within each row, each needle is preferably spaced apart between about 3 mm and 8 mm from adjacent needles and, in the exemplary embodiment, the spacing (Dr) is about 4.8 mm. The spacing between each row is preferably between about 2 mm and 6 mm and, in the exemplary embodiment, the spacing (Dc) is about 3.5 mm. In addition, the needles are slightly offset with respect to adjacent rows, including a first distance (Of) of about 2 mm as measured between a needle in an adjacent row and a second distance (Os) as measured from a second side of a needle.

[0033] In other embodiments, the size and spacing of the perforations can vary. For example, other patterns for the perforations can be used and varying spacing between the perforation in different regions of the glove. In addition, the perforations can have differing diameters and need not be uniform. In the exemplary embodiment, the support structure is configured as a second roller closely spaced from the first roller.

[0034] It should be appreciated from the foregoing that the present invention provides a golf glove having sections made of elastic material and inelastic material, strategically positioned about the glove to enhance fit and performance. Sections of the inelastic material define a plurality of perforations having a diameter of less than about 2 mm spaced substantially throughout both a palmar side and a dorsal side of the glove. The perforations enhance dissipation of heat and moisture out of the glove.

For crying out loud, it’s a golf glove with needle holes throughout! Yes, funny ha-ha; but seriously, I truly believe that creating a well drafted patent application on a simple invention in a unique manner so that it has a shot at patentability is one of the most difficult documents to create. Unfortunately, no one will believe that statement unless they have actually done it. Oh well, such is life.

Dave Dawsey - Keeping an Eye on Golf Glove Inventions

PS – Click HERE to read about Acushnet’s patent application directed to an acupuncture golf glove.

PPS – Check out other golf glove related posts HERE

Comments