Will Callaway Move Away from Their HEX Aerodynamics Technology?

Most golfers can look at a pile of unlabeled golf balls and easily identify the Callaway balls because of their unique HEX aerodynamic technology; but in the future will we be seeing more traditional circular dimples on Callaway balls? One could be led to that conclusion after reading a Callaway golf ball patent that issued this week as USPN 7547259 titled “Aerodynamic Pattern for a Golf Ball.”

Here is an interesting bit of history from the patent:

The patent describes the invention as:

Interesting looking dimple pattern!

The patent goes on to explain:

Cool stuff.

Dave Dawsey - Tracking Golf Ball Inventions

PS – click here for other golf ball posts

Here is an interesting bit of history from the patent:

Golfers realized perhaps as early as the 1800's that golf balls with indented surfaces flew better than those with smooth surfaces. Hand-hammered gutta-percha golf balls could be purchased at least by the 1860's, and golf balls with brambles (bumps rather than dents) were in style from the late 1860's to 1908. In 1908, an Englishman, William Taylor, received a British patent for a golf ball with indentations (dimples) that flew better and more accurately than golf balls with brambles. A.G. Spalding & Bros., purchased the U.S. rights to the patent (embodied possibly in U.S. Pat. No. 1,286,834 issued in 1918) and introduced the GLORY ball featuring the TAYLOR dimples. Until the 1970s, the GLORY ball, and most other golf balls with dimples had 336 dimples of the same size using the same pattern, the ATTI pattern. The ATTI pattern was an octahedron pattern, split into eight concentric straight line rows, which was named after the main producer of molds for golf balls.

The only innovation related to the surface of a golf ball during this sixty year period came from Albert Penfold who invented a mesh-pattern golf ball for Dunlop. This pattern was invented in 1912 and was accepted until the 1930's. A combination of a mesh pattern and dimples is disclosed in Young, U.S. Pat. No. 2,002,726, for a Golf Ball, which issued in 1935.

The traditional golf ball, as readily accepted by the consuming public, is spherical with a plurality of dimples, with each dimple having a circular cross-section. Many golf balls have been disclosed that break with this tradition, however, for the most part these non-traditional golf balls have been commercially unsuccessful.

Most of these non-traditional golf balls still attempt to adhere to the Rules Of Golf as set forth by the United States Golf Association ("USGA") and The Royal and Ancient Golf Club of Saint Andrews ("R&A"). As set forth in Appendix III of the Rules of Golf, the weight of the ball shall not be greater than 1.620 ounces avoirdupois (45.93 gm), the diameter of the ball shall be not less than 1.680 inches (42.67 mm) which is satisfied if, under its own weight, a ball falls through a 1.680 inches diameter ring gauge in fewer than 25 out of 100 randomly selected positions, the test being carried out at a temperature of 23+-1 degrees C., and the ball must not be designed, manufactured or intentionally modified to have properties which differ from those of a spherically symmetrical ball.

The patent describes the invention as:

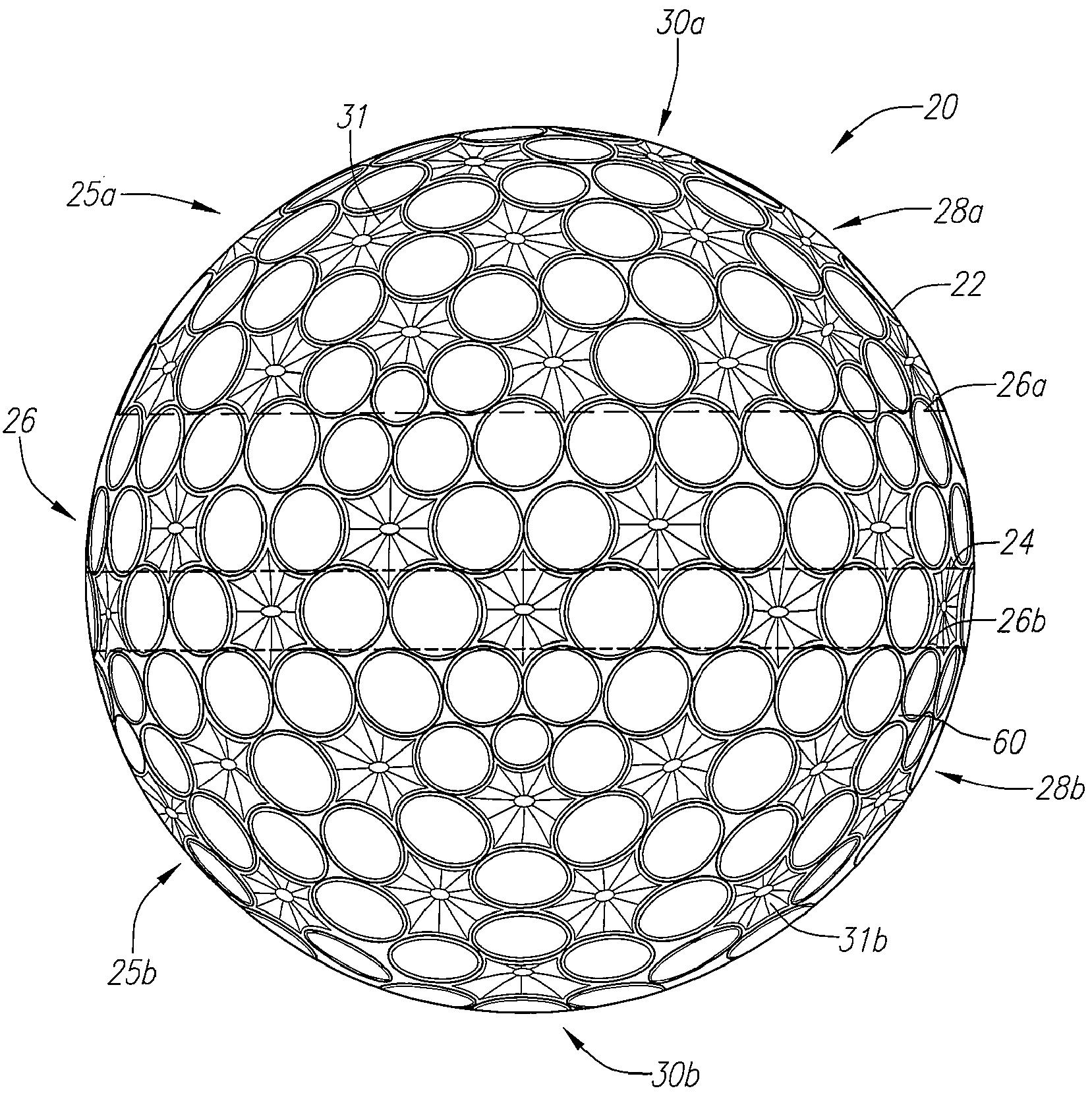

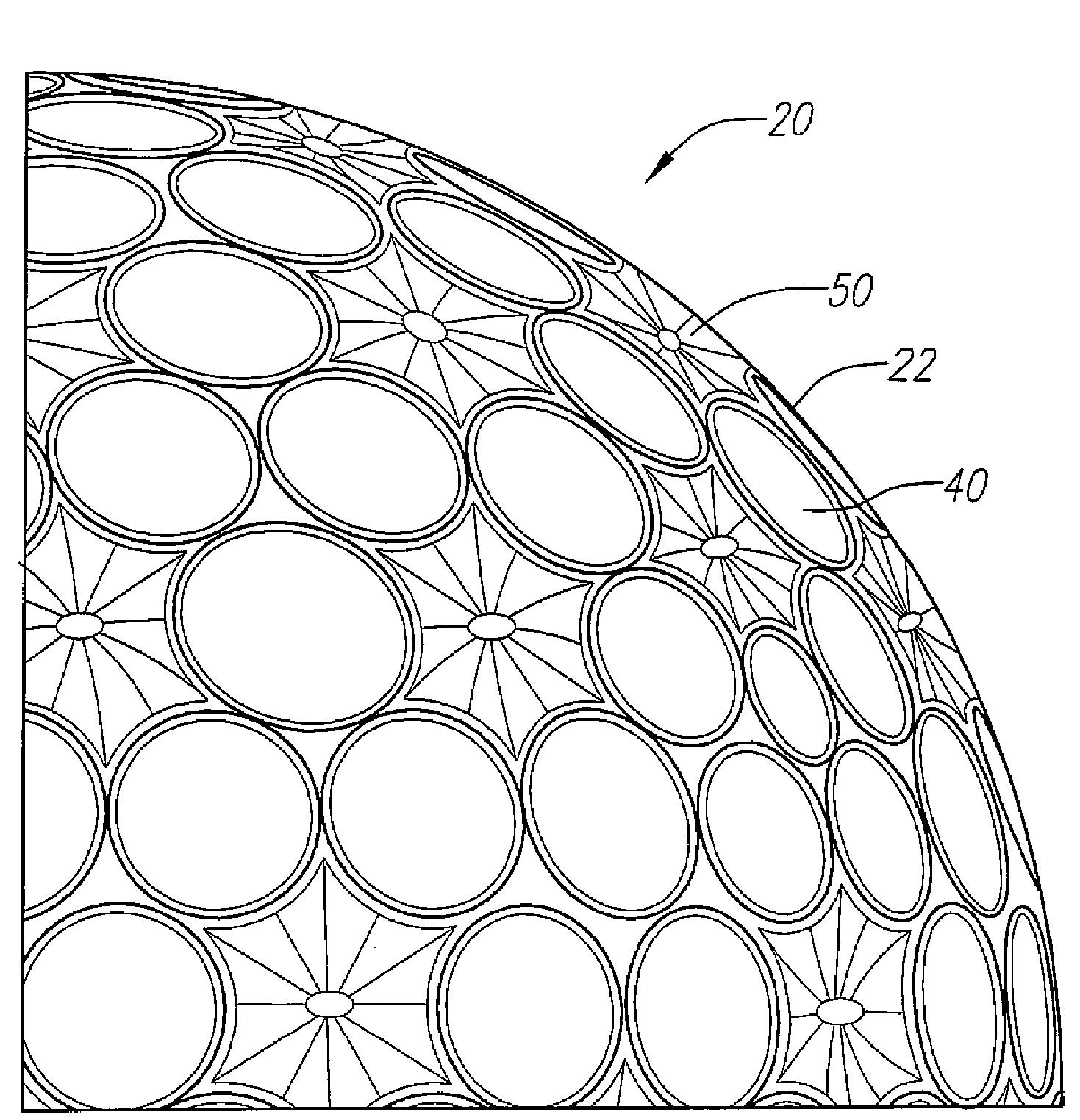

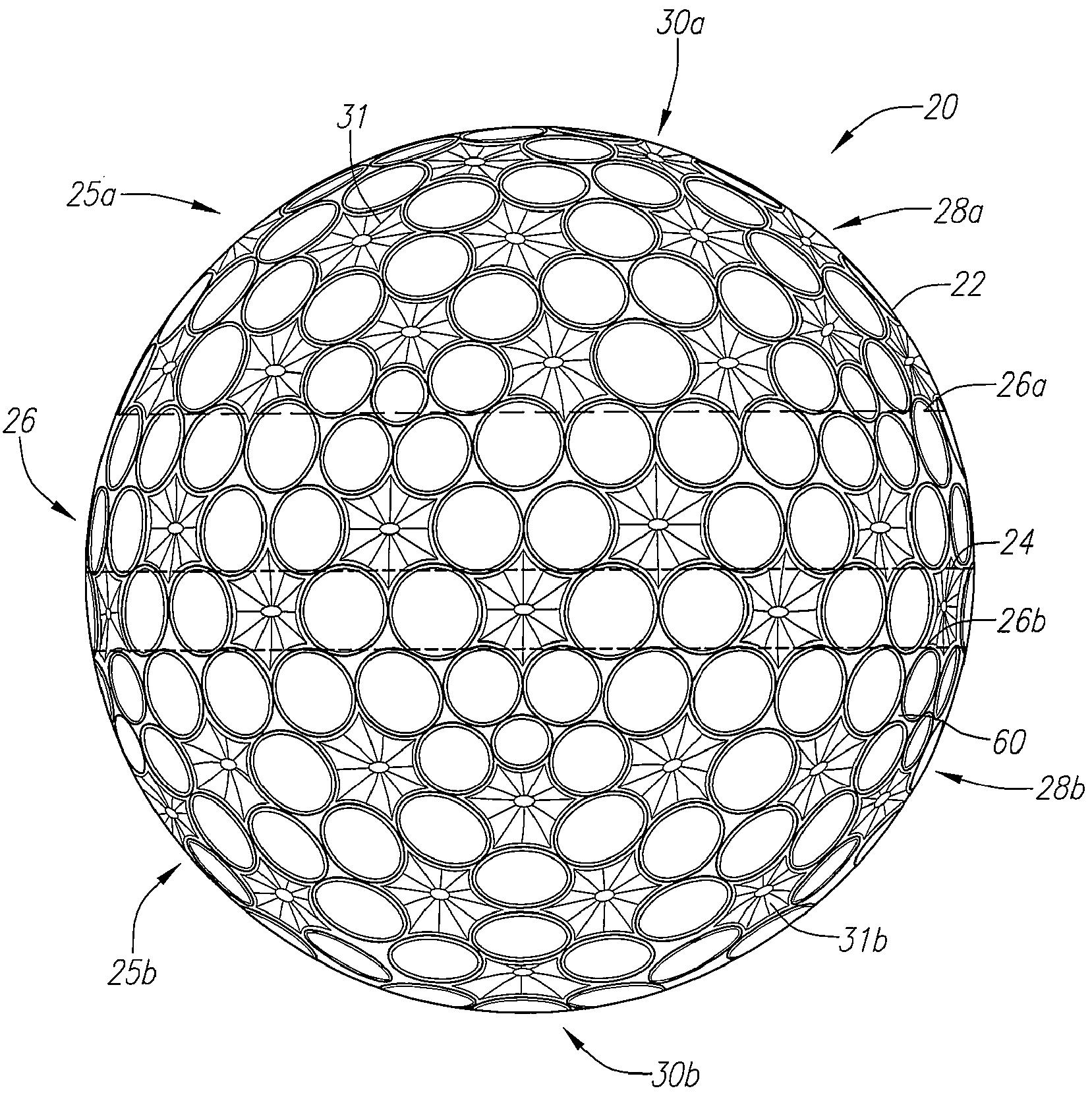

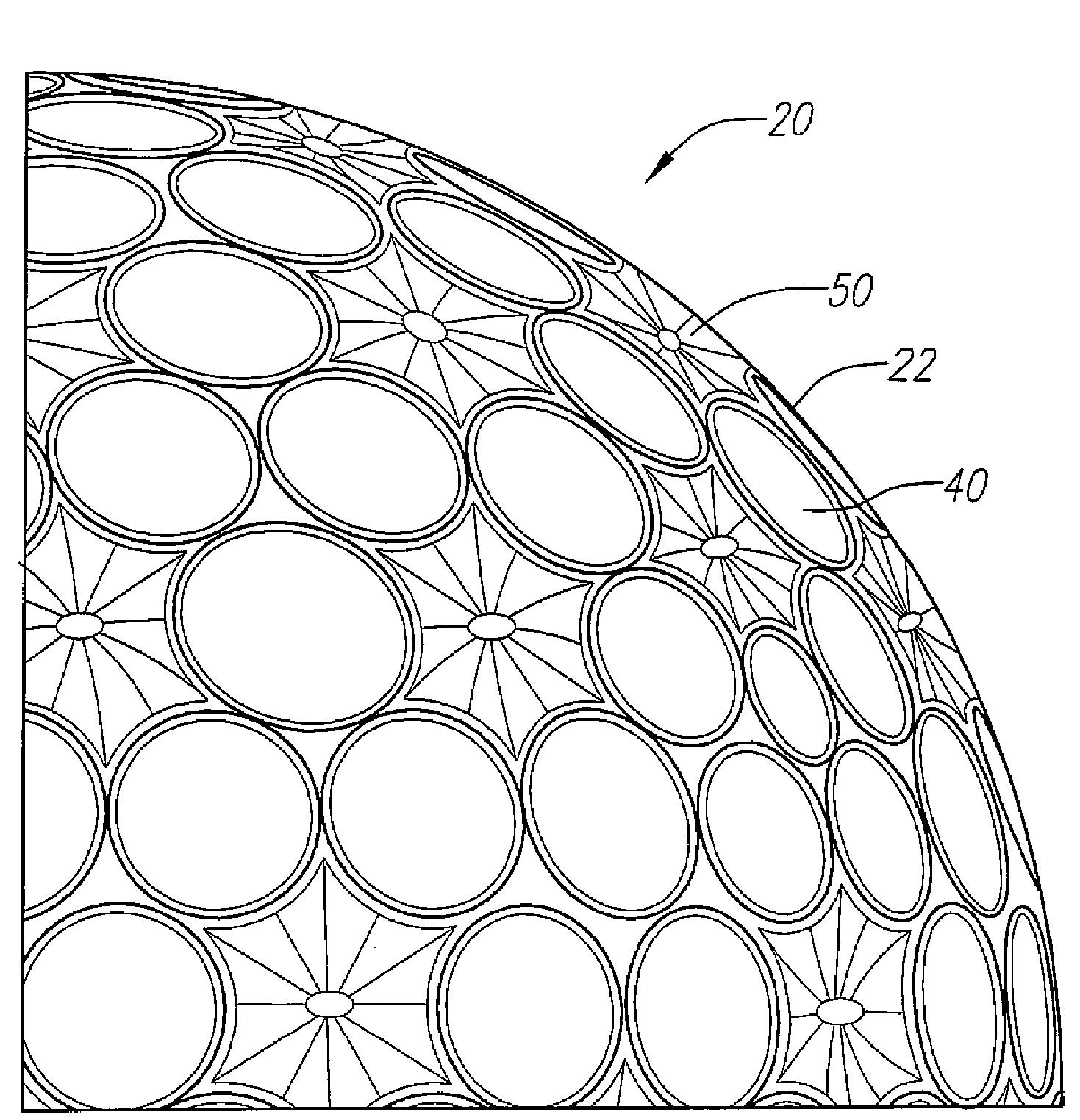

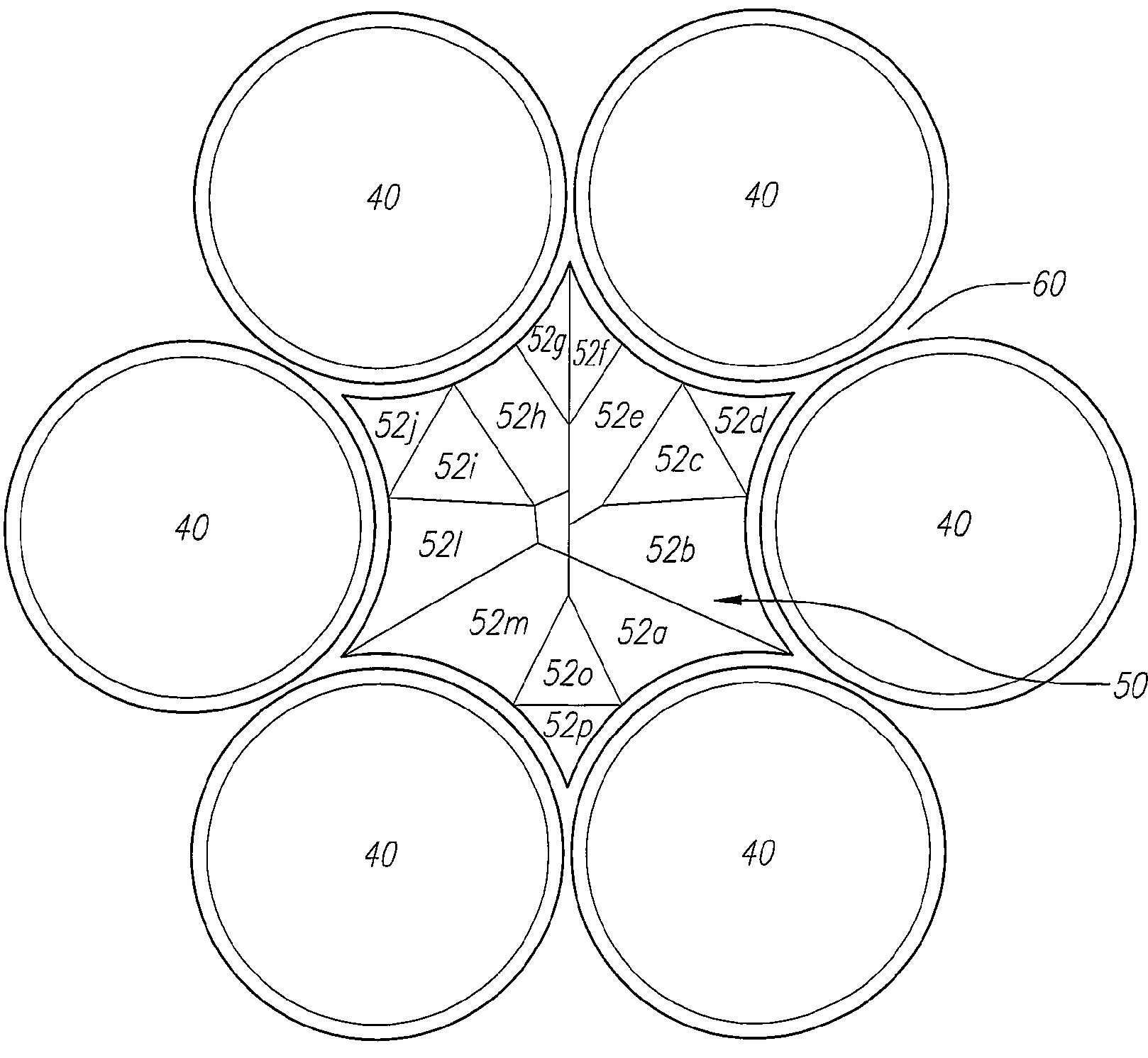

A golf ball having traditional dimples and a tubular lattice structure is disclosed herein. The golf ball has dimples and a plurality of lattice members that form multi-faceted polygons. Each of the plurality of lattice members has an apex and the golf ball of the present invention conforms with the 1.68 inches requirement for USGA-approved golf balls. The interconnected lattice members form a plurality of polygons, preferably hexagons and pentagons. Each of the lattice members preferably has a continuous contour.

Preferably, the golf ball 20 comprises between 50 to 250 multi-faceted polygons 50 and 200 to 300 dimples 40. More preferably, the golf ball 20 comprises 60 to 100 multi-faceted polygons 50 and 220 to 260 dimples 40.

In a preferred embodiment, the multi-faceted polygons 50 and dimples 40 cover 70% to 90% of the surface area of the surface 22 of the golf ball 20. More preferably, the multi-faceted polygons 50 and dimples 40 cover 78% to 85% of the surface area of the surface 22 of the golf ball 20. In a preferred embodiment, the land area 60 covers 10% to 30% of the surface 22 of the golf ball 20. Most preferably, the land area 60 covers 15% to 22% of the surface 22 of the golf ball 20. Preferably the land area 60 ranges from 1.60 square inches to 2.00 square inches, more preferably from 1.70 square inches to 1.80 square inches, and most preferably 1.784 square inches.

In a preferred embodiment, the golf ball 20 has six sets of dimples 40 that each has a different diameter varying from 0.160 inch to 0.190 inch. The pole dimples 42, which are included in the plurality of dimples 40, preferably has the smallest diameter.

As shown in FIG. 3, each multi-faceted polygon preferably has more than ten facets 52. In a preferred embodiment, each multi-faceted polygon 50 has sixteen facets 52a-52p. Preferably each multi-faceted polygon 50 is surrounded by six dimples 40.

Preferably, each multi-faceted polygon 50 has a depth ranging from 0.004 inch to 0.01 inch. Preferably, each multi-faceted polygon 50 has an entry angle of approximately 14 degrees and an entry radius of approximately 0.025 inch.

Cool stuff.

Dave Dawsey - Tracking Golf Ball Inventions

PS – click here for other golf ball posts

Comments