Cool Golf Grip Patents Don’t Come Along Everyday, So Check This Out!

This week Eaton Corp., parent company of Golf Pride, was issued a rather interesting golf grip patent. The patent is USPN 7458902 titled “Changeable Golf Grip.” I know…. I also said “what is a CHANGEABLE golf grip?”

Before we dive into the invention, a bit of background is in order:

OK, so the idea sounds smart, but how is it implemented? Well, the patent explains…

Interesting concept, but I am not sure I like the part about “a modified (reduced length) golf club shaft.”

Dave Dawsey - Keeping an Eye on Golf Grip Patents

Before we dive into the invention, a bit of background is in order:

Originally, golf club grips consisted primarily of a leather wrap around a handle. Later, molded rubber slip-on grips became available and are still in wide use today. A recent variation on the molded rubber grip is the concept of using a rubber sleeve or underlisting on the handle with a leather or synthetic leather wrap spirally wrapped around the underlisting, or alternatively a single panel cover over the underlisting. Grips are made today from a wide variety in construction and combinations of materials.

There still exists a need for an improved changeable grip that imparts or receives shock or force to or from a shock imparting implement. A changeable grip provides greater flexibility in selecting a specific grip for a given application or for use under a wide variety of conditions. It allows the user to select exactly the type of grip needed under the given conditions for the desired application. It is also desirable for the grip to be constructed in a manner that provides a firm grasp with little or no slippage and with good resistance to torque as well as exhibiting good shock absorbing qualities.

A changeable grip further allows for a wide variety of enhancing features to the grip such as the addition of a vibration damper for example, or added weights for swing weight control, or even still multiple types of gripping surfaces with interchangeable sleeves of combinations of various materials. Swing weight control, handle stiffness, flex control, shock absorption are just some of the important factors in improving the impact from the implement. The concept of tailoring a grip to provide the user with multiple options minimizes the need for multiple grips and multiple implements.

Thus, it is desirable to have a changeable grip that allows the user to select the right fit and feel for the handle or shaft of a shock imparting implement or tool to meet the needs of the user in a given application.

OK, so the idea sounds smart, but how is it implemented? Well, the patent explains…

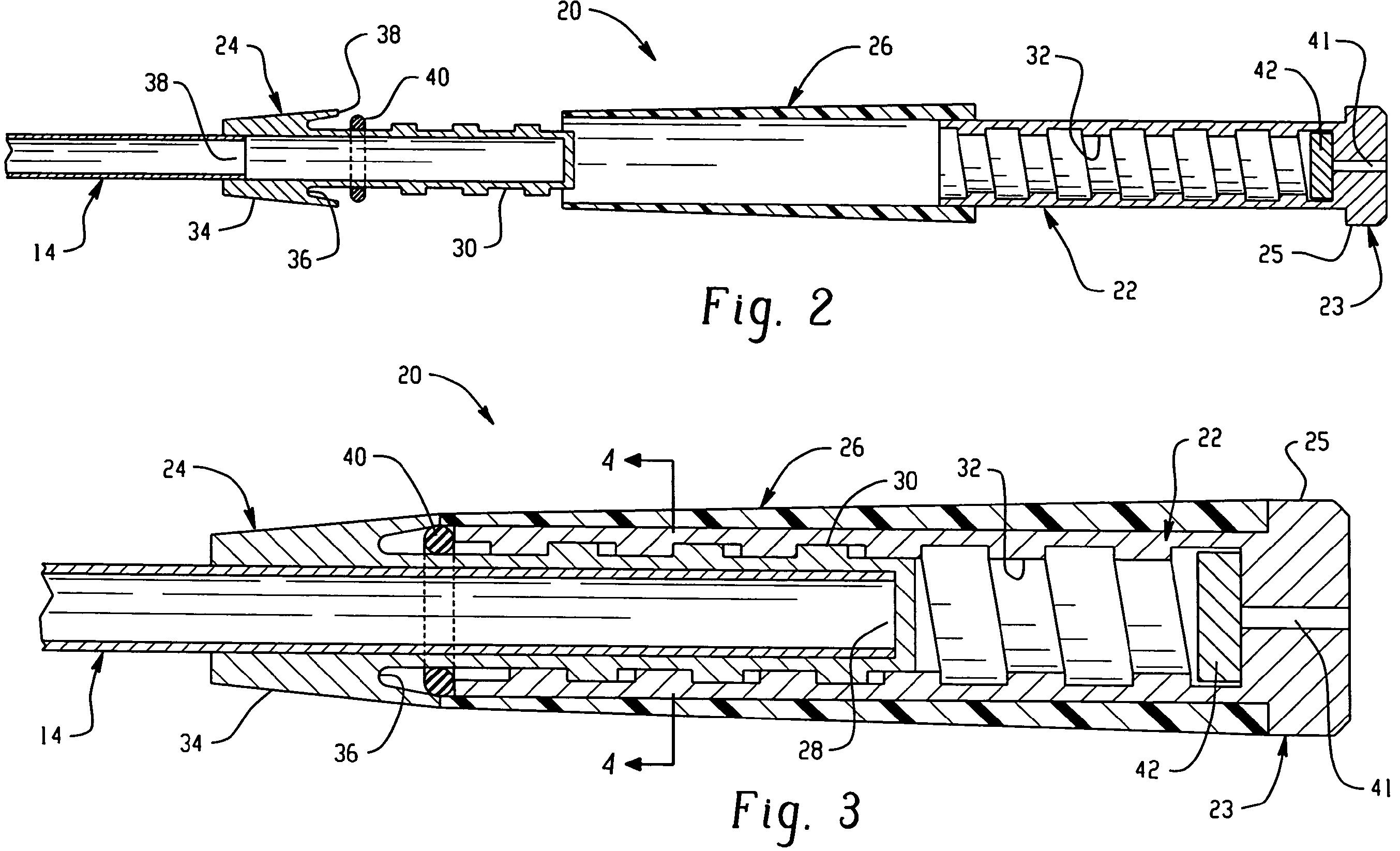

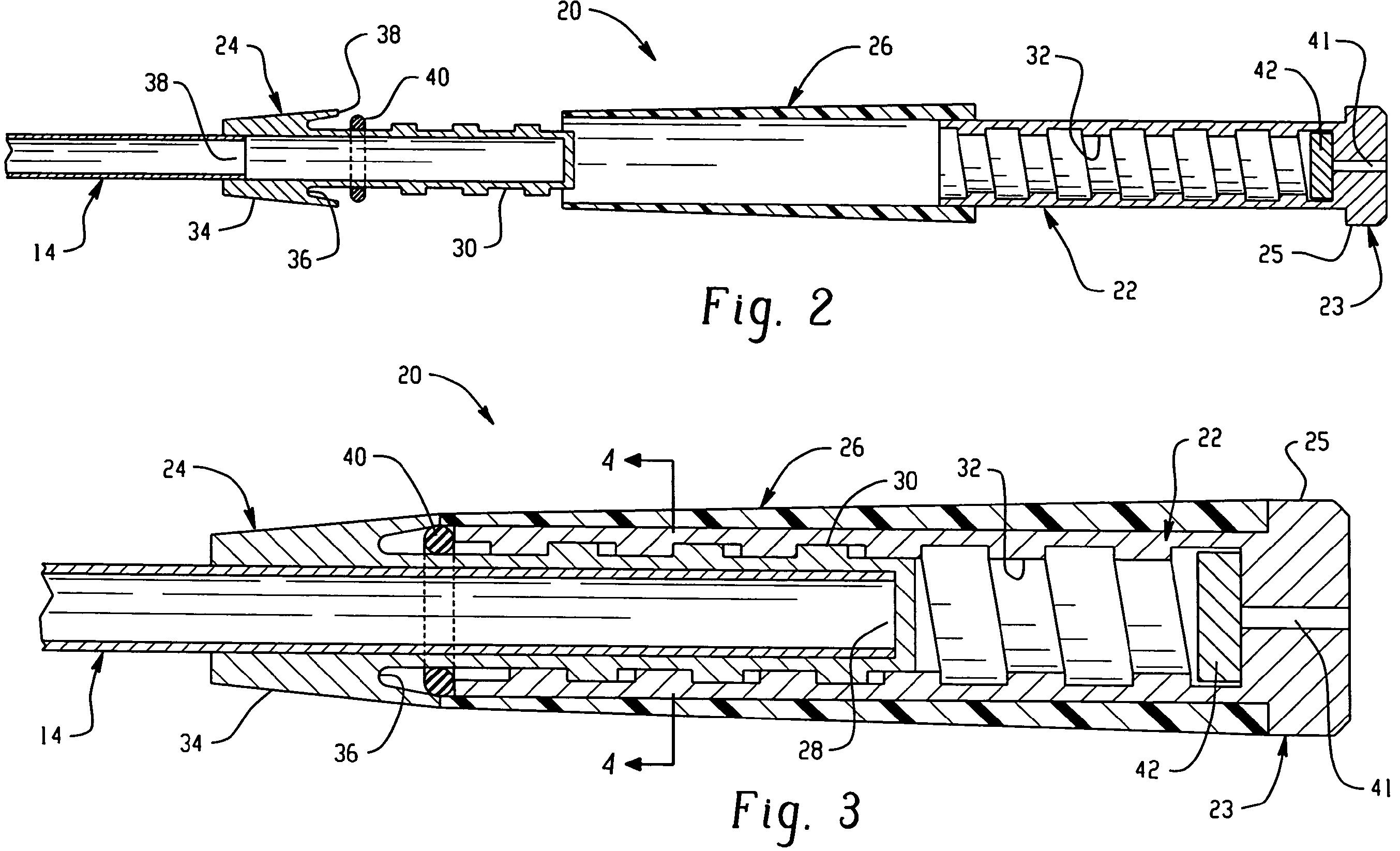

Referring to FIG. 2, there is shown a sectional view of a partially disassembled changeable grip generally designated 20 according to the present disclosure. The changeable grip 20 basically comprises three parts or elements: a body 22, a ferrule element 24, and a sleeve 26. The body 22 is threadably attached to the ferrule element 24 which is mounted on the golf club shaft 14. A sleeve 26 covers the body 22. As will be explained in greater detail later herein with respect to each of these three parts, there are a wide variety of options and enhancing features that these three parts provide the user.

The ferrule element 24 is securely attached to the upper end 28 of a modified (reduced length) golf club shaft 14. An upper end 30 of the ferrule element 24 has a male threaded portion constructed to threadably receive a female threaded inner surface 32 of the body 22. The threaded portions 30, 32 of the ferrule element 24 and body 22 preferably are square threads but any conventional threading of these components are suitable as long as they function to secure the body 22 to the ferrule element 24. Ferrule element 24 has a tapered lower end 34 that tapers in the direction of the golf club head. An annular groove 36 in a top edge 38 of the lower end 34 of the ferrule element is particularly suited for a lock washer 40 to maintain the secure attachment of the body 22 to the ferrule element 24. Lock washer 40 may be made of any suitable material and/or shape for this purpose including but not limited to being made of an elastomeric or metal material. The ferrule element 24 and the body 22 of grip 20 are made from a metal like stainless steel or titanium, or a metal alloy, or a composite material like a carbon fiber, graphite fiber, or metal matrix composite. Any similar lightweight high strength material is well suited for this purpose.

Interesting concept, but I am not sure I like the part about “a modified (reduced length) golf club shaft.”

Dave Dawsey - Keeping an Eye on Golf Grip Patents

PS – check out other golf grip patent related posts here

Comments