Have Enough Fiber in Your Diet? How About in Your Golf Ball?

Is it the next ProV? I doubt it, but Acushnet did have an interesting golf ball patent application publish this week. The application published as US Pub. No. 20080254913 titled “Golf Ball With A Translucent Layer Comprising Composite Material,” which includes the following description:

OK, a golf ball with a composite layer that includes fibrous material (which may be ferromagnetic)! Pretty cool.

The application goes on to explain:

Next time you take a violent swing at one of those innocent white balls, think of the amount of R&D that goes into producing a commercially successful golf ball!

Dave Dawsey - Tracking Golf Ball Patents

PS – click here for other golf ball posts

A golf ball having at least a core and a composite layer comprising a fibrous material and a matrix material is disclosed. The fibrous material may comprise a polymer, glass or metal. The matrix material preferably comprises a translucent polymer. In one embodiment of the present invention, the fibrous material comprises a ferromagnetic material and the golf ball is subjected to induction heating to improve adhesion between adjacent ball layers. The golf ball may additionally comprise a translucent cover layer surrounding the composite layer or an intermediate layer disposed between the composite layer and the core.

OK, a golf ball with a composite layer that includes fibrous material (which may be ferromagnetic)! Pretty cool.

The application goes on to explain:

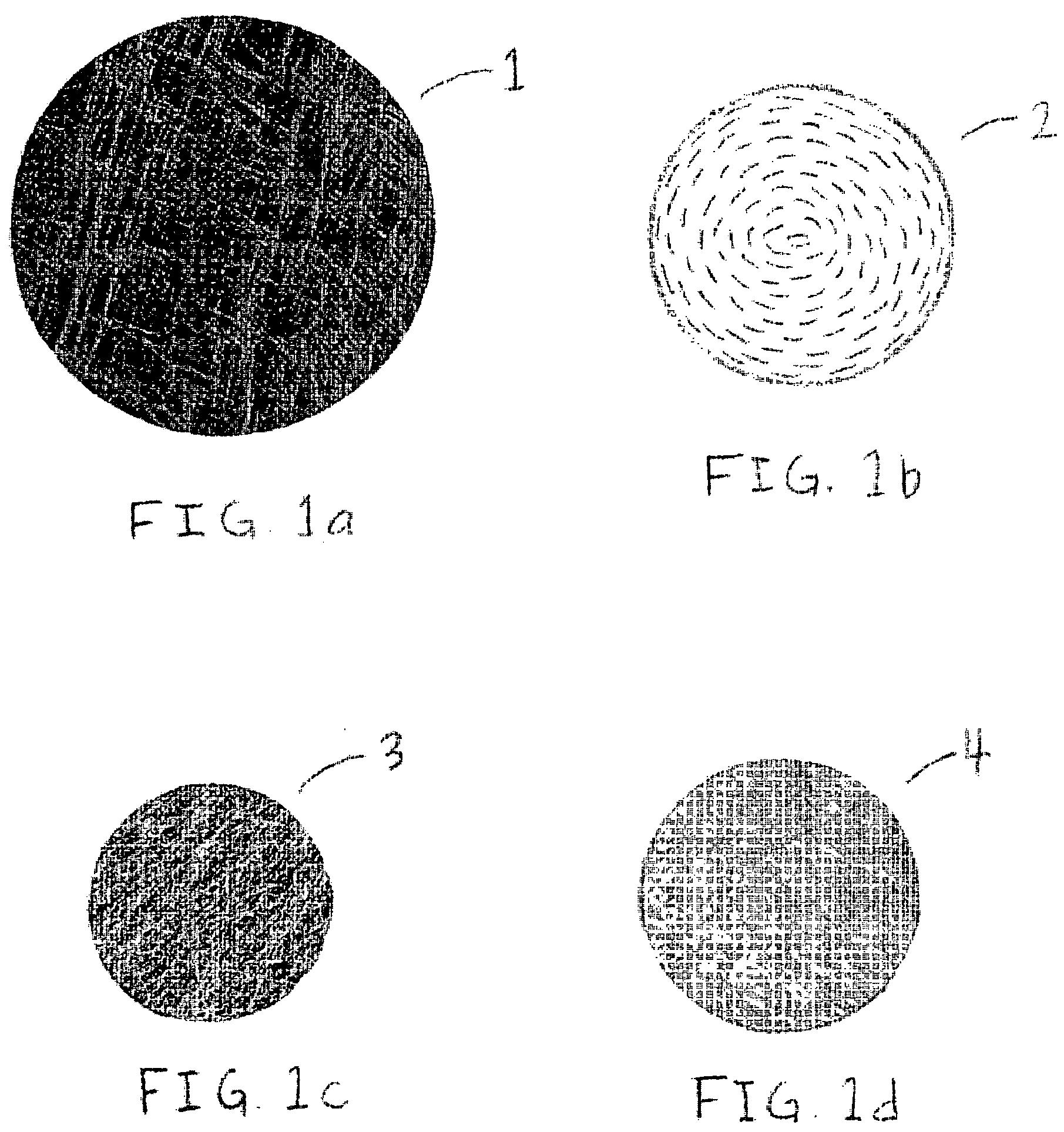

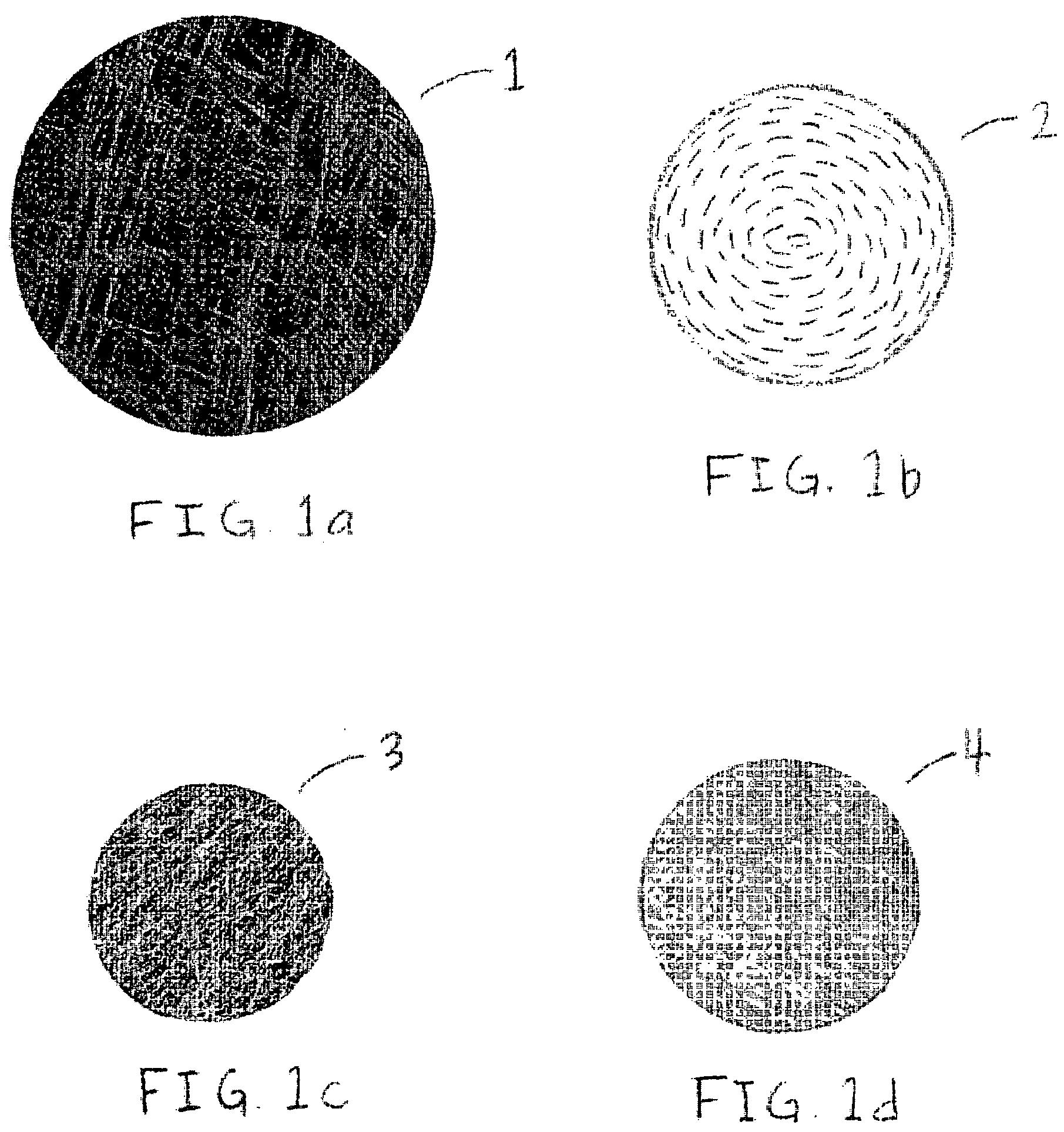

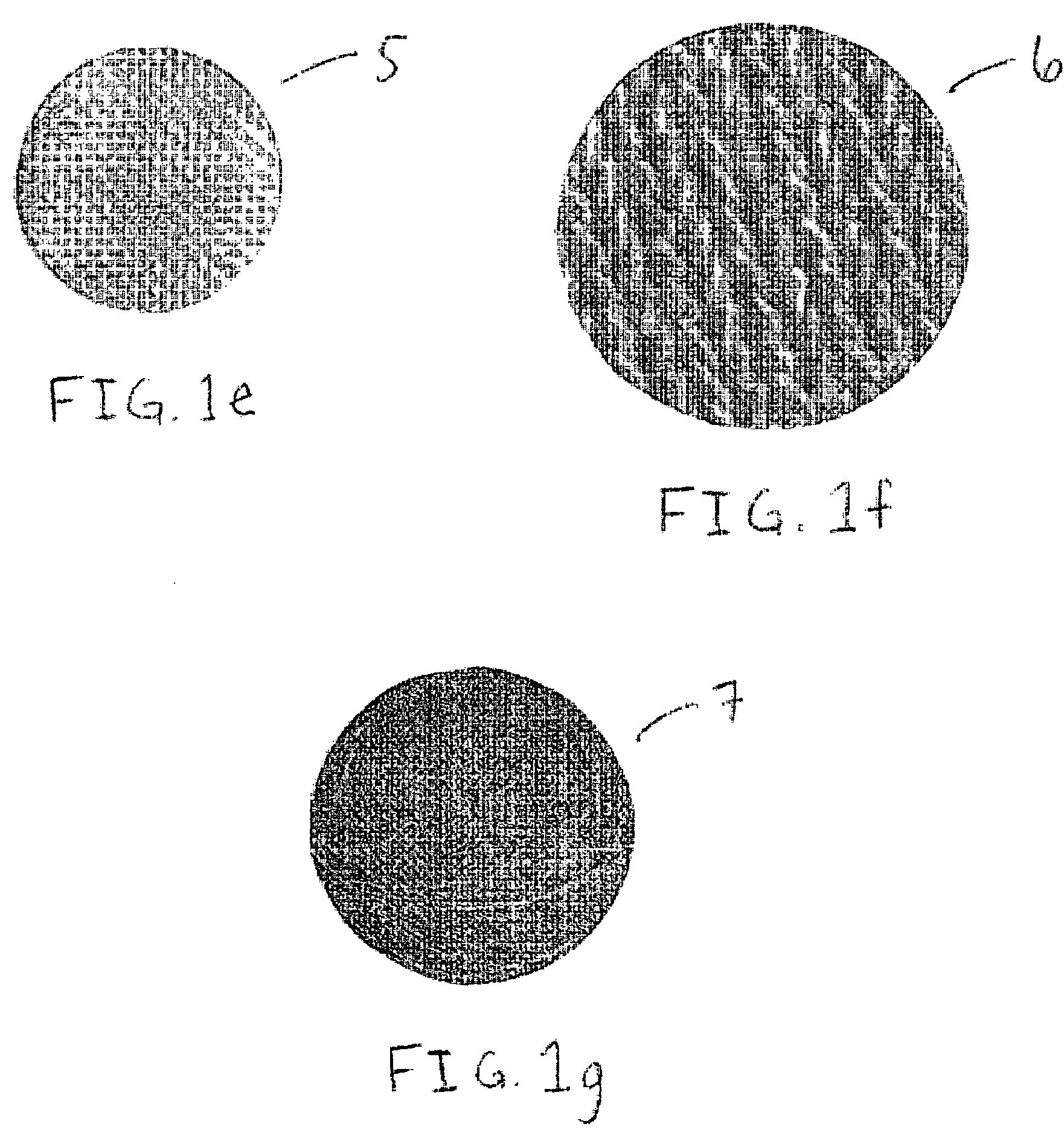

[0046] This invention is primarily directed to golf balls having a core and at least one layer comprising visible fibrous elements, which include high aspect ratio fibers or filament that may be randomly dispersed therein or ordered in a translucent binder or matrix. The fibrous elements may also contain high aspect ratio flakes to create a unique visual effect. The visible fibrous elements and flakes may be present within, or beneath, a transparent or translucent cover layer. Visible fibrous elements and flakes may be disposed within, beneath or above any subsurface layer, e.g., a vapor transmission resistance layer, a high modulus layer, a hoop stress layer, an intermediate layer or an outer core layer. The cover may comprise a polymeric matrix material molded around fibrous elements, filaments or flakes. The core layer may be a single-piece or dual-core. A dual-core may comprise solid or wound layers, and may have an inner core comprising a fluid, i.e., a gas or liquid.

[0047] The incorporation of a transparent or translucent material into the construction of the golf ball enables direct consumer observation of technological features embedded within, or present beneath, the transparent or translucent layer. Additionally, the fibrous elements or particulate materials present within or beneath the translucent or transparent cover layer, or above the opaque surface of the core or intermediate layer but below the translucent or transparent cover layer provide the aesthetic features of the golf ball. The visible fibrous elements may result in better golf ball properties including, but not limited to, improved resiliency, decreased moisture vapor transmission rate, and improved adhesion between adjacent ball layers.

.

.

.

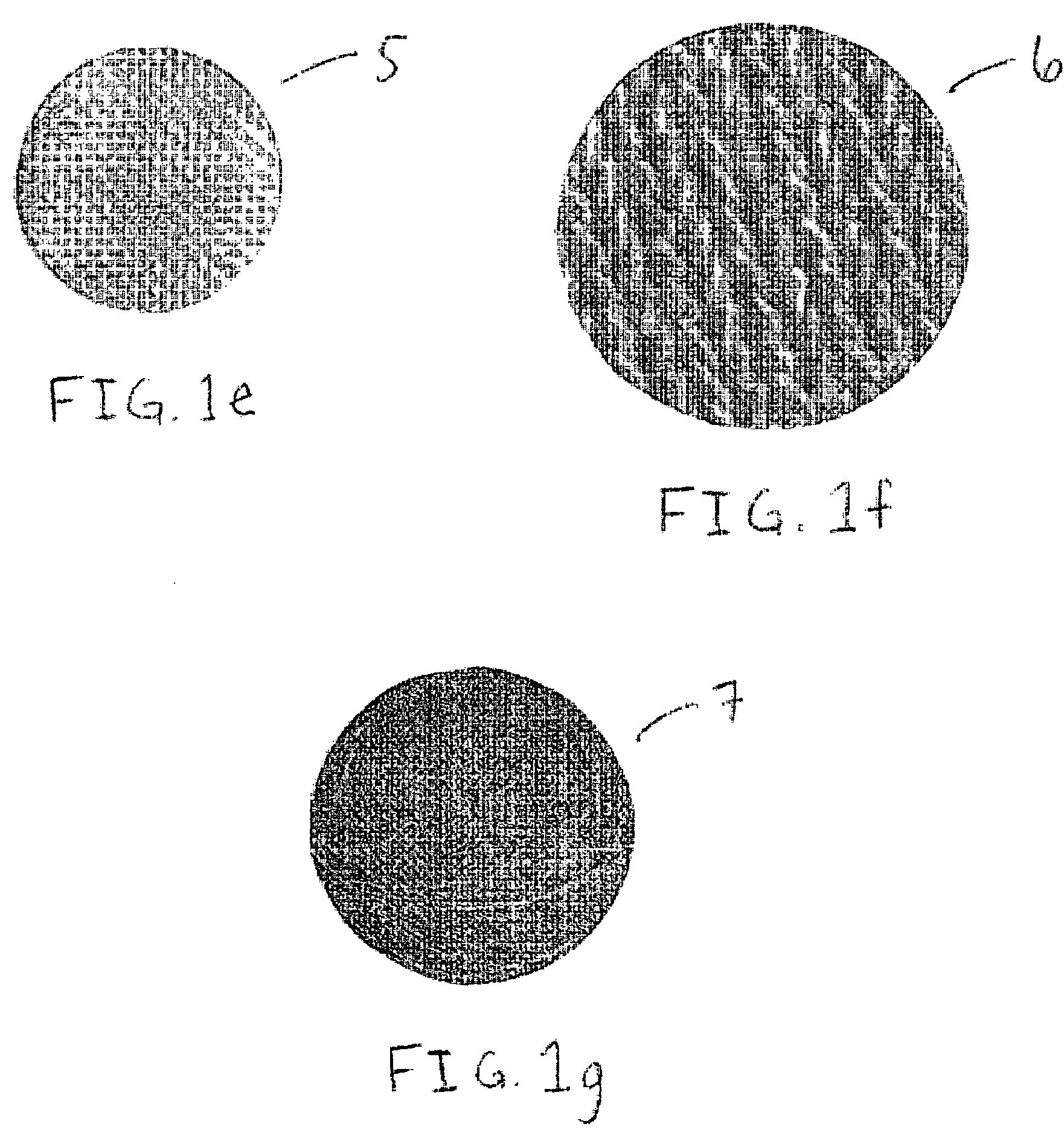

[0056] Alternatively, fibers may be ordered in any array, as shown in FIG. 1b. In accordance with this aspect of the invention, golf ball 2 includes magnetized metal fibers or ferromagnetic fibers dispersed through an uncured or unset polymeric matrix material, injected around a core, and subjected to a magnetic field before curing or setting of the matrix material. Due to the magnetic field, the magnetized metal or ferromagnetic fibers can orient in a parallel or circular fashion.

.

.

.

[0064] In accordance with another embodiment of the present invention, a golf ball may comprise at least a core and a cover layer and fibrous material comprising a metal or metals susceptible to induction heating (1H). Commonly-owned U.S. Patent Application Publication No. 2006/0148590 teaches a golf ball comprising metal materials heated through induction heating and is incorporated herein by reference in its entirety. Induction heating of the metal filament material can improve adhesion between layers comprising the metal filament material and adjacent layers. The process of IH includes applying an alternating current (AC) to an induction coil to generate a magnetic field, and supplying a work piece around which the magnetic field works. The work piece in this instance is the golf ball comprising fibrous material comprising metals sensitive to the magnetic field. Metal filament materials sensitive to magnetic fields resist the rapidly changing magnetic fields produced by AC within the induction coil, resulting in friction which produces heat known as hysteresis heating.

[0047] The incorporation of a transparent or translucent material into the construction of the golf ball enables direct consumer observation of technological features embedded within, or present beneath, the transparent or translucent layer. Additionally, the fibrous elements or particulate materials present within or beneath the translucent or transparent cover layer, or above the opaque surface of the core or intermediate layer but below the translucent or transparent cover layer provide the aesthetic features of the golf ball. The visible fibrous elements may result in better golf ball properties including, but not limited to, improved resiliency, decreased moisture vapor transmission rate, and improved adhesion between adjacent ball layers.

.

.

.

[0056] Alternatively, fibers may be ordered in any array, as shown in FIG. 1b. In accordance with this aspect of the invention, golf ball 2 includes magnetized metal fibers or ferromagnetic fibers dispersed through an uncured or unset polymeric matrix material, injected around a core, and subjected to a magnetic field before curing or setting of the matrix material. Due to the magnetic field, the magnetized metal or ferromagnetic fibers can orient in a parallel or circular fashion.

.

.

.

[0064] In accordance with another embodiment of the present invention, a golf ball may comprise at least a core and a cover layer and fibrous material comprising a metal or metals susceptible to induction heating (1H). Commonly-owned U.S. Patent Application Publication No. 2006/0148590 teaches a golf ball comprising metal materials heated through induction heating and is incorporated herein by reference in its entirety. Induction heating of the metal filament material can improve adhesion between layers comprising the metal filament material and adjacent layers. The process of IH includes applying an alternating current (AC) to an induction coil to generate a magnetic field, and supplying a work piece around which the magnetic field works. The work piece in this instance is the golf ball comprising fibrous material comprising metals sensitive to the magnetic field. Metal filament materials sensitive to magnetic fields resist the rapidly changing magnetic fields produced by AC within the induction coil, resulting in friction which produces heat known as hysteresis heating.

Next time you take a violent swing at one of those innocent white balls, think of the amount of R&D that goes into producing a commercially successful golf ball!

Dave Dawsey - Tracking Golf Ball Patents

PS – click here for other golf ball posts

Comments