Grab Your Shag Bag Full of Beat Up Golf Balls and Try to Wrap Your Head Around This Invention

As you can imagine, I browse through a lot of golf patent applications every week and see many inventions that could never make it to market simply because they are directed to such a small pool of golfers that it would never be financially viable. Golf ball heaters/warmers generally fall into this category. Yes, hitting the links on the first sunny 40 degree day in the middle of winter is great, but hitting a ball that has been sitting in your trunk for the past 2 months of sub-freezing temperatures can be a little jarring. Even still, I would not buy a ball warmer, which is why I generally don’t even look at patent applications with titles indicating that they have anything to do with heating a golf ball.

For some reason yesterday I didn’t skip over an application titled “Device For Heating A Golf Ball,” and I am glad. The application immediately had my attention because it was submitted by Nike Golf. A little surprising, after all they have a lot of smart people that generally have a solid understanding of what will sell; so I read on. The application published as US Pub. No.

The application goes on to explain:

[0001] The present disclosure relates to a handheld clamp device for applying heat to a golf ball.

[0002] The game of golf is an increasingly popular sport at both the amateur and professional levels. A wide range of technologies related to the manufacture and design of golf balls are known in the art. Such technologies have resulted in golf balls with better performance and longer durability. However, golf balls nonetheless continue to suffer from several deficiencies.

[0003] For example, the cover layer of a golf ball will wear out and degrade over time due to repeated impacts with a golf club. Although materials used in the cover layer are generally resilient, the cover layer will eventually crack due to the blunt force of being hit by a golf club. The golf ball then exhibits less than optimal play characteristics, and the ball will ultimately become unusable. Amateur golfers generally prefer to minimize the costs of purchasing new golf balls. Therefore, a variety of methods and systems have been developed to repair the surface layer of a golf ball.

[0004] As another example, a golfer may be required to purchase several sets of golf balls in order to achieve different play characteristics. For example, different dimple patterns may affect the aerodynamic properties of the golf ball during flight, or a difference in hardness may affect the rate of backspin. A golfer may therefore wish to carry and use several sets of golf balls in order to achieve the desired play characteristics over the course of a round of golf. Namely, a golfer may use one type of golf ball for driving and another for putting. This presents an inconvenience to the golfer, as well as increased costs.

[0005] Both of the above discussed deficiencies can be addressed by applying heat to a golf ball. However, known methods and devices for applying heat to a golf ball are generally inadequate for a variety of reasons. For example, current methods for repairing golf balls with heat use equipment that is generally bulky and expensive. Such equipment generally cannot be used by a golfer, but is instead industrial scale machinery. Furthermore, known portable golf ball heaters merely warm a golf ball so as to protect from cold weather, and so generally do not attain sufficiently high temperatures to achieve the above discussed effects.

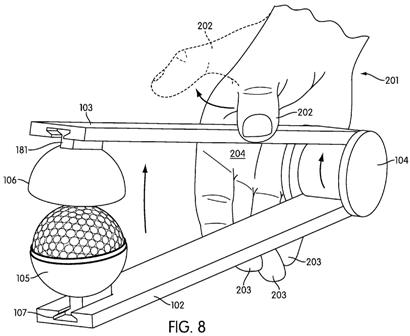

[0007] The present disclosure relates to a handheld clamp device for applying heat to a golf ball. The device may have two lever arms, each attached at one end to a pivot. A golf ball receiving unit for holding a golf ball may be attached to each of the lever arms at the opposite end as the pivot. Each golf ball receiving unit may include a heating element, and may be made up of an external housing and an internal heating surface.

[0008] In another aspect, the internal heating surface of each golf ball receiving unit may contain a pattern. The pattern can be the reverse of a desired pattern to be formed on the surface of a golf ball. The pattern on the internal heating surface may be a dimple pattern. When in use, the handheld device may heat the surface of a golf ball such that the pattern on the internal heating surfaces forms a dimple pattern into the surface of the golf ball.

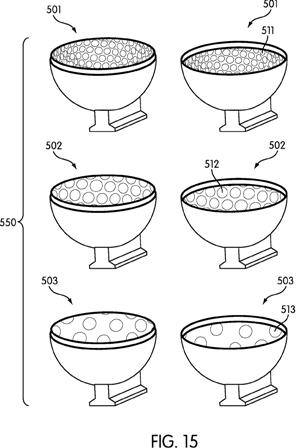

[0009] The handheld clamp device may be included as part of a kit, along with a set of multiple golf ball receiving unit pairs, and sometimes one or more golf ball. In this embodiment, each of the several pairs of golf ball receiving units may include different patterns therein. These patterns may be different dimple patterns. In some embodiments, these different patterns may correspond to different play characteristics of a golf ball. These different patterns may also have a constant total dimple volume.

.

.

.

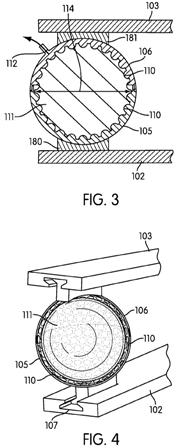

[0044] In certain embodiments, one or both of the first internal heating surface 154 and the second internal heating surface 156 may have a pattern therein. When in use, device 101 may impart this pattern to the surface of a golf ball by heating the golf ball to a predetermined temperature and embossing the pattern into the surface of the golf ball. The pattern can generally be any type of pattern. For example, the pattern may be a functional pattern that affects how the golf ball plays during a round of golf, or the pattern may be a cosmetic pattern that only changes the appearance of the surface of the golf ball. In particular embodiments, the pattern may be a dimple pattern. FIGS. 1, 3-7 and 14 show a representative dimple pattern 110. Generally, as in known in the art, a “reverse” dimple pattern is the inverse of a desired dimple pattern, such that each location where a dimple indent is to be formed on a golf ball contains a raised bump corresponding to that dimple. A “reverse” dimple pattern is therefore a type of dimple pattern, and the dimple pattern 110 may be understood as any type of pattern that results in the golf ball having corresponding dimples.

.

.

.

[0067] In other embodiments, the device 101 may allow a user to repair an existing pattern on a finished golf ball 191. FIG. 16 shows a kit 601 that may be used for this purpose. Kit 601 includes the handheld clamp device 101, a first golf ball receiving unit 105, a second golf ball receiving unit 106, and at least one finished golf ball 191. The finished golf ball 191 may have a

dimple pattern already formed on the surface thereof. The golf ball 191 in kit 601 may have a cover layer that is capable of being embossed by the pattern 110 when the device heats the golf ball. Specifically, the golf ball cover layer should have a formulation which is be capable of being embossed at a temperature of less than about 140.degree. C.[0068] In this embodiment, the pattern 110 on the internal heating surfaces of the first golf ball receiving unit 105 and the second golf ball receiving unit 106 is a dimple pattern that corresponds to the existing dimple pattern on the finished golf ball 191. Therefore, the user may play several rounds of golf with the finished golf ball 191, until the surface of the finished golf ball 191 exhibits cracks and deformations. At this time, the user may then use the device 101 and associated first golf ball receiving unit 105 and second golf ball receiving unit 106 to impart the pattern 110 onto the finished golf ball 191, thereby restoring the dimple pattern 110 on the golf ball 191 to its original state.

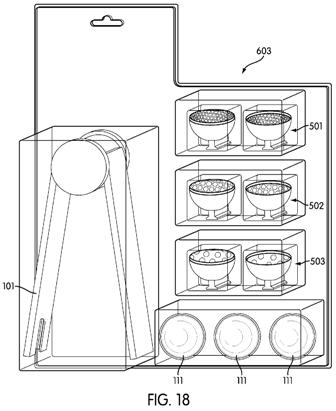

[0069] In yet other embodiments, the device 101 may be used to impart various different patterns to a golf ball as desired by a user. FIGS. 17 and 18 show kits that may be used for this purpose. Kit 602 as shown in FIG. 17 contains the handheld clamp device 101, and a set 550 of three golf ball receiving unit pairs. In particular, kit 602 includes first golf ball receiving unit pair 501, second golf ball receiving unit pair 502, and third golf ball receiving unit pair 503. Kit 603 as shown in FIG. 18 is the same as kit 602, but further includes at least one finished golf ball 111 that does not have a dimple pattern thereon. Aside from the lack of dimples, the golf ball 111 may otherwise be the same as golf ball 191. Both the golf ball 111 and the golf ball 191 are finished golf balls, meaning that they include all material layers as are commonly used in regulation play golf balls, such as (for example) a cover layer, a coating layer and a top coat.

OK, I buy the novelty of being able to purchase a smooth ball and do your own dimple imprinting, and I suspect most purchasers would do it a few times before deciding that it is easier to just purchase finished golf balls; but the “repair” angle…. don’t most amateurs lose a golf ball long before it is in need of repair?

Also, can it really be that easy? Call me a pessimist, but this seems like an idea that is easy to say out loud or put in writing, but very hard to actually pull off. What would the final finish look like? Regardless, it would be pretty cool if they could actually pull it off (although I wouldn’t spend my hypothetical R&D dollars on it).

David Dawsey – Keeping an Eye on Golf Ball Technology

PS – click HERE to read more interesting golf ball patent posts