Do You Know the Shape of the Inside of Your Golf Shafts?

Frankly, I had never even considered the shape of the inside of a golf club shaft until today. Naturally, the inside of a shaft must be round, right? Not true. This week an interesting patent application published that is directed specifically to non-circular bores of a golf shaft. The application published as USPN 20090215550 titled “Matrix Composite Golf Club Shaft and Mandrel” and describes the invention as:

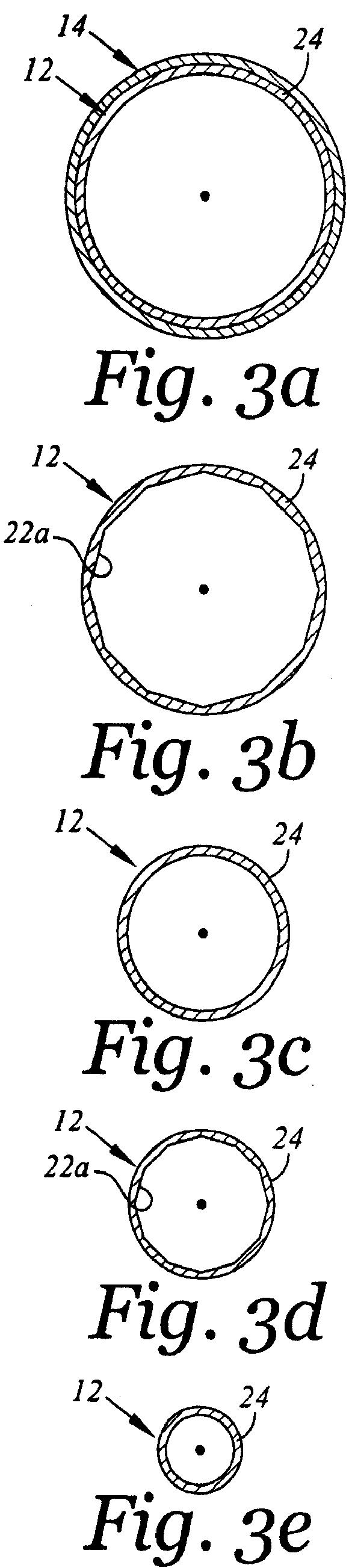

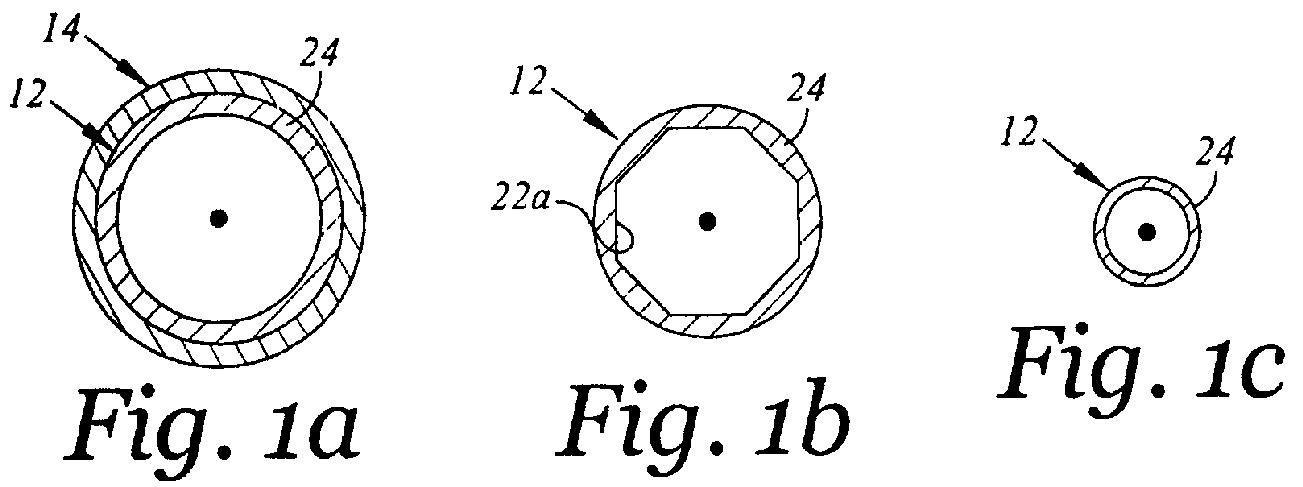

A golf club shaft is provided that has a grip end opposite a head end and defining a length of the shaft extending between those two ends. The shaft has a tubular cross-section over at least one portion of the shaft length which cross-section has a substantially circular outer periphery and a polygon inner periphery formed of a plurality of between 4 and 24 flats, and preferably formed of 8-16 flats. A mandrel having the shape of the inner periphery of the shaft is also provided, as is a method of forming the shaft that uses the mandrel and composite matrix materials.

Check out these drawings:

The application goes on to explain:

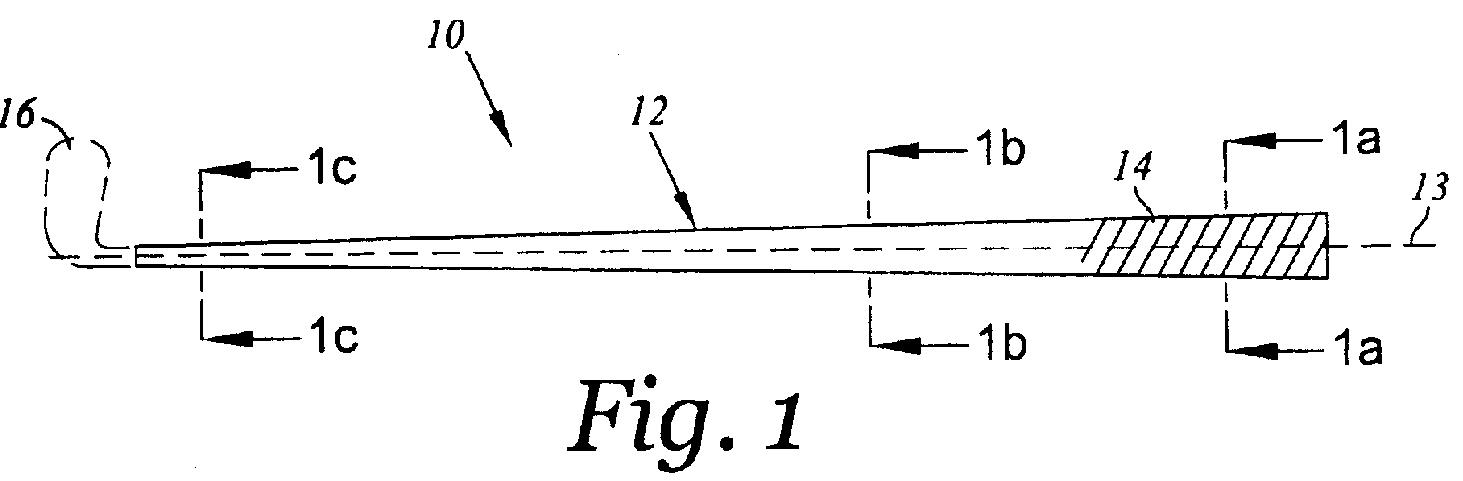

[0001] Golf club shafts were historically made by turning lengths of wood on a lathe to form a tapered shaft with a round cross-section. But the wood was heavy and of variable stiffness, resulting in inconsistent performance and lower velocity at the golf club head. The wooden shafts were replaced with various tubular metal shafts such as steel and titanium which provided more consistent stiffness control and that, because of the lighter weight, provided a higher velocity at the golf club head. The metal shafts are now being replaced by tubular, composite matrix shafts which allow and even lighter and stiffer shaft than those made of metal. These matrix shafts are typically formed of a graphite epoxy matrix created either by winding a plurality of graphite strands, preferably in the form of unidirectional, pre-impregnated fiber tape in predetermined patterns around a tapered steel mandrel as in U.S. Pat. No. 4,157,181, or by, or by taking a sheet of previously laid-up strands and wrapping pre-cut segments around the tapered mandrel as in U.S. Pat. No. 4,023,801. The strands can be varied in size, spacing, material and orientation in order to vary the stiffness of the resulting tapered shaft. In both manufacturing methods, the graphite strands and mandrel are placed in an autoclave where high temperature and pressure bond the graphite and epoxy, or shrink-wrap plastic is placed around the mandrel and composite matrix and the assembly is baked in an oven to cure the matrix. The mandrel is then removed leaving a light, tubular shaft with a thin cross-section that is circular both outside and inside.

[0002] While the matrix composite is lighter than wood and metal, it has a uniform stiffness that does not vary in the radial direction.

BRIEF SUMMARY

[0003] It is believed possible to achieve a shaft with desirable stiffness and performance characteristics, and a potentially lighter shaft, by varying the inner periphery of the cross-section, as described herein. A shaft having improved, selectably variable and desirable stiffness is provided by varying the shape of the inside of the tapered tubular shaft of graphite matrix material, and in particular by providing a plurality of flats on the inner surface of the shaft. The bends formed in the matrix when the matrix bends over the corners of adjoining flats is believed to result in a localized stiffness increase along the length of the bend. A shaft with a cross-section having a polygon interior profile is believed to have higher bending strength, at least along certain planes, and a lower torsional resistance. Thus, a shaft is believed capable of having a lighter weight, increased stiffness, improved hoop strength and lower torque. By altering the bending stiffness of the shaft along the entire shaft length, or by altering the bending strength in any given region, the performance of the club head can be varied, and preferably varied to provide a lower backspin on the ball driven with such a club, resulting in a longer carry distance.

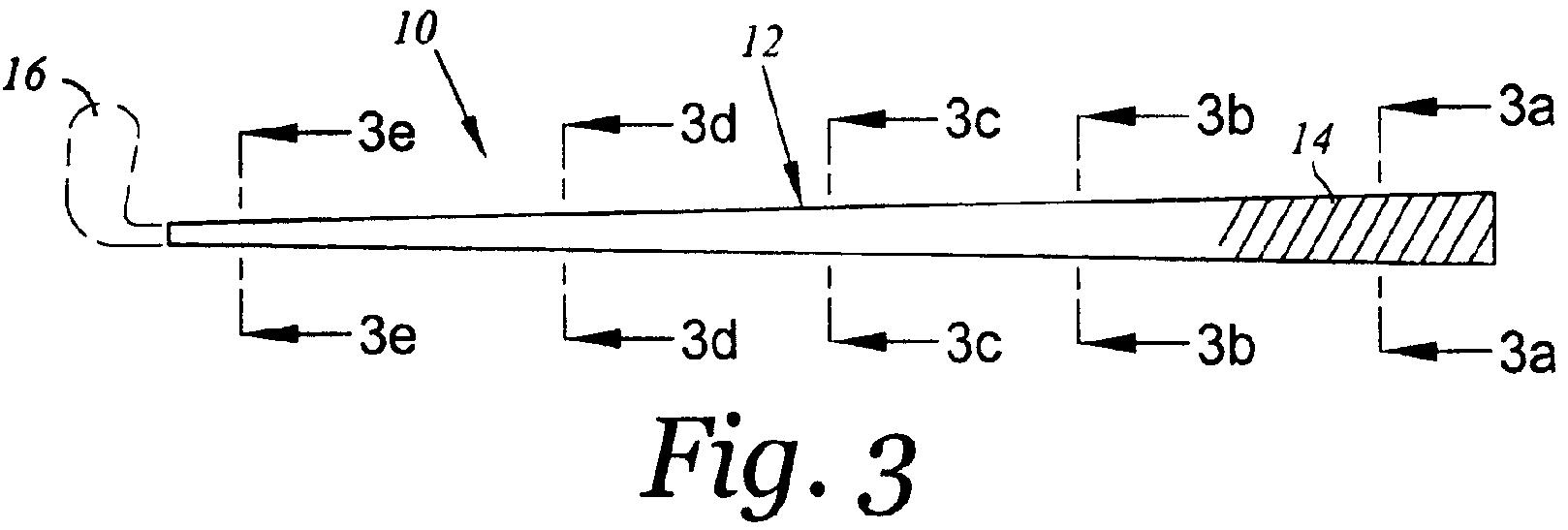

[0004] The shaft is achieved by using a mandrel having a plurality of flat sides along a length of the mandrel. The flats preferably extend for a substantial length of the shaft and preferably end before the head end of the shaft. A circular inner diameter of the shaft for about two or more inches from the head is believed desirable. From four to 24 sides are believed suitable, with 8-16 flat sides being preferred. Advantageously, the numbers of sides are multiples of two, and preferably multiples of four. The shafts made using the mandrel have a generally circular outer periphery, and preferably a substantially circular outer periphery with an inner periphery that has a series of flats corresponding to the flats on the mandrel. The cross-section is thus a generally circular on the outside and a polygon on the inside along the portion of the shaft corresponding to the flat-sided portion of the mandrel, but preferably with a circular inside diameter adjacent the head end of the shaft.

[0005] In a further embodiment, the flats extend along a first length extending from at or adjacent to the gripping end of the shaft toward a portion in the middle of the shaft, with a circular middle section and a second length of flats extending from the middle section toward the head end of the shaft but preferably changing to a circular section adjacent the head end of the shaft.

[0006] In more detail, there is advantageously provided a golf club shaft having a grip end opposite a head end and defining a length of the shaft extending between those two ends. The shaft has a tubular composite matrix shaft tapering from a larger grip end toward a smaller head end, the shaft having a cross-section over a first portion of the length which cross-section has a generally circular outer periphery and a polygon inner periphery formed of a plurality of between 4 and 24 flats.

[0007] This basic shaft can have numerous variations, including a preferred variation wherein the polygon has from 8 to 16 sides and is substantially circular. The shaft preferably has an even number of sides, and the first portion of the length preferably extends for a substantial length of the shaft, either continuously or intermittently. That substantial length can be achieved using one or more further portions of the length spaced apart from the first section, where the further portions have a cross-section which has a substantially circular outer diameter and a polygon inner periphery formed of a plurality of flats. Such further portions are separated by yet another portion of the shaft having a generally circular inner diameter. Still further variations include a shaft having a generally circular inner periphery and a substantially circular outer periphery adjacent the head end of the shaft. The inner periphery of the head end of the shaft can be configured to receive a post of a golf club head.

[0008] Advantageously, each flat has a width that narrows as the cross-section moves from the grip end of the first portion toward the head end of the first portion. Alternatively, each flat could have a constant width along its length. Further, it is believed advantageous if at least a plurality of the flats abut the adjacent flat at a sharp corner

or a rounded corner, although such abutting corners could be rounded and could in fact be formed by the profile of a substantially circular inner periphery.[0009] There is also provided a mandrel for a golf club shaft, where the mandrel has an outer surface configured to mate with and provide the above described inner surface of the shaft. This mandrel thus has a grip end roughly sized to be gripped by a person’s hands to swing the club, and opposite a head end, with a length of the shaft extending between those two ends. The mandrel comprises a shaft tapering from the larger grip end toward a smaller head end, with the shaft having an outer periphery that is generally circular and further having a first portion that has a polygon outer periphery formed of a plurality of between 4 and 24 flats.

[0010] Numerous variations can be made to this basic mandrel, including the preferred variation of a polygon with from 8 to 16 sides and an outer periphery is substantially circular. The mandrel preferably has a polygon with an even number of sides, and the first portion of the length extends for a substantial length of the shaft, either continuously or intermittently. An intermittent spacing of the portions can include a second portion of the length spaced apart from the first section, where the second portion has a cross-section which has a substantially circular outer diameter and a polygon inner periphery formed of a plurality of flats, and where the first and second portions are separated by a portion of the shaft having a generally circular inner diameter. The mandrel preferably has a generally circular inner periphery and a substantially circular outer periphery adjacent the head end of the shaft. The inner periphery of the shaft is advantageously shaped to receive a post of a golf club head.

[0011] The flats on the mandrel advantageously each have a width that narrows as the cross-section moves from the grip end of the first portion toward the head end of the first portion. Alternatively, the width of the flats could remain constant. Advantageously, at least a plurality of the flats abut the adjacent flat at a sharp corner, although the at least a plurality of the flats could also abut the adjacent flat at a rounded corner.

[0012] There is also provided a method of making a golf club shaft, wherein any one of the above mandrels is wrapped with a composite matrix. The wrapped shaft and composite matrix are subjected to sufficient pressure and sufficiently high temperature to cause the matrix to bind strands in the matrix to form a unitary composite structure. That structure is then separated from the shaft.

[0013] There is also provided a shaft means for providing a shaft with areas of varying stiffness extending along at least a substantial portion of the length of the shaft, said shaft means having a cross-section with a substantially circular outer periphery and a polygon inner periphery along said substantial portion.

Pretty cool!

David Dawsey – Monitoring Golf Shaft Inventions

PS – check out other golf shaft patent posts here