Acushnet Patent Application Publishes Directed to Golf Ball Recycling System

That’s right, green is in (and very PC). Still, I was surprised to see an Acushnet patent application publish today titled “Recyclable Golf Ball and Method Therefor.” (US Pub. No. 20100056305)

Just close your eyes and imagine golf ball recycling kiosks in every pro shop. Perhaps one at the local grocery store; you know, right next to the can recycling kiosk, the change counting kiosk, the DVD rental kiosk, and the game with the hanging claw and crappy stuffed animals. I think I just heard a tear fall and hit your keyboard. When you read the number of patent applications that I do, eventually you will start to believe that kiosks are about to take over the world.

So, what does Acushnet have in mind? Well, I will let the patent application explain the situation:

OK, I am all for recycling but do we need to give little kids and retired people an incentive to cruise along the OB stakes in hopes of capitalizing on some poor golfer’s misfortune? I mean they already seem to do it just for the thrill of the hunt.

The application goes on to explain:

I can’t wait to cash in a load of old beat-up balls for a Starbucks gift card! While my initial reaction is to shake my head and laugh, I have no doubt that the idea would work and undoubtedly would end up recycling tons of material that would otherwise be thrown away (or just roll back and forth in your trunk for years). For that reason I say, bring on the ball recycling kiosks (and install them right next to a swing training kiosk)!

David Dawsey – Keeping an Eye on Golf Ball Inventions

PS – click HERE to read more interesting golf ball patent posts

Just close your eyes and imagine golf ball recycling kiosks in every pro shop. Perhaps one at the local grocery store; you know, right next to the can recycling kiosk, the change counting kiosk, the DVD rental kiosk, and the game with the hanging claw and crappy stuffed animals. I think I just heard a tear fall and hit your keyboard. When you read the number of patent applications that I do, eventually you will start to believe that kiosks are about to take over the world.

So, what does Acushnet have in mind? Well, I will let the patent application explain the situation:

BACKGROUND OF THE INVENTION

[0002] Golf balls typically contain materials that are difficult to recycle. In particular, golf balls contain thermoset polymers which, like rubber in tires, do not degrade and pose serious threats to the environment. In 1844, Charles Goodyear obtained U.S. Pat. No. 3,633 directed to sulfur vulcanization and further stated that "[n]o degree of heat, without blaze can melt it . . . . It resists the most powerful chemical reagents." Although Goodyear's sulfur vulcanization provided a significant breakthrough to the industrial revolution, he also created one of the most difficult materials to recycle.

[0003] There have been efforts to develop methods of recycling and reclaiming rubber, especially in view of the increasing amount of scrap rubber produced by used golf balls. For instance, commonly owned U.S. Pat. No. 5,609,535 to Morgan (herein "the Morgan patent"), which is incorporated herein by reference in its entirety, discloses a method for restoring used golf balls. In addition to the environmental benefits of reprocessing used golf balls, consumers benefit from the reprocessed balls' reduced price, which results from lower manufacturing costs.

[0004] To date, known golf ball recycling efforts merely consist of refurbishing recovered golf balls from golf course hazards. These recovered balls are inspected, cleaned, possibly repackaged, and then resold usually by entities not affiliated with the original golf ball manufacturer. Some recovered balls received a new clear coat to resemble new golf balls. However, such practices can negatively affect the aerodynamic properties of the balls, because the new coat can flood the dimples.

[0005] It is difficult for golf ball manufacturers to collect old golf balls for recycling because most golfers lose their golf balls while playing and very few golf balls actually become unplayable. Furthermore, there are no known distribution channels for millions of players to return used unplayable golf balls to the manufacturers.

[0006] There is also no known method that creates financial incentives for golf ball users to recycle used golf balls. Thus, a need exists for a system that can recycle unplayable golf balls and to remove them from the environment.

OK, I am all for recycling but do we need to give little kids and retired people an incentive to cruise along the OB stakes in hopes of capitalizing on some poor golfer’s misfortune? I mean they already seem to do it just for the thrill of the hunt.

The application goes on to explain:

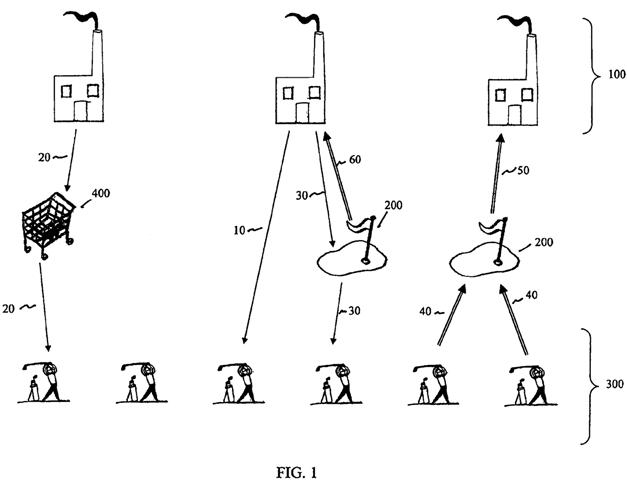

[0019] The present invention is generally directed to a method for recycling golf balls. Forward distribution, or sale channels, from golf ball manufacturers to consumers are known. As illustrated in FIG. 1, golf ball manufacturers 100 use several forward distribution channels to convey golf balls to golfers, or other consumers, 300.

[0020] In one example, golf ball manufacturers 100 can sell golf balls directly to golfers 300 through direct distribution channels 10, direct mail orders, catalog orders, Internet orders or phone orders. In another example, golf ball manufacturers 100 sell or convey golf balls to golf facilities 200, such as golf courses, pro-shops, driving ranges, or professional golf tournaments, and these golf facilities would then sell the golf balls to golfers 300. In another example, golf ball manufacturers 100 sell or convey golf balls to sporting goods stores, or department stores with a sporting goods department, other retail stores 400, and golfers 300 or other consumers would then purchase golf balls at the sporting goods stores and department stores.

[0021] In an embodiment of the present invention, reverse distribution channels 40 and 50 are provided to golfers 300 and golf facilities 200 to return used golf balls back to golf ball manufacturers 100. Alternatively, in this embodiment, golf manufacturers 100 can use dynamic distribution channel 60 to convey golf balls to golf facilities 200 under a lease, buy-back, or service agreement. Subsequently, golf facilities 200 use dynamic distribution channel 60 to return used golf balls back to original manufacturers 100 for recycling.

[0022] In another embodiment, golf balls comprising 100% thermoplastic polymers are either returned to their original manufacturers 100 or third-party recyclers for complete recycling.

[0023] In each embodiment, the golf facilities 200 or golfers 300 receive a reward for golf balls returned.

[0024] FIG. 2 provides an overview of a golf ball's life-cycle 500. In a first stage 510, the raw materials used to produce golf balls are acquired by manufacturers 100. The raw materials typically include but are not limited to thermoset polymers, thermoplastic polymers, and additives. Significant amounts of fossil fuel energy must be expended in order to extract, transport, and process such raw materials. Similarly, in a second stage 520, manufacturers 100 transform the raw materials into golf balls using manufacturing processes that further expend fossil fuel energy. Because fossil fuel energy is required for raw material acquisition as well as manufacturing, both stage 510 and stage 520 emit greenhouse gases that adversely affect the environment.

[0025] In third stage 530, the golf balls are used by golfers 300, who directly or indirectly purchase the golf balls from golf manufacturer 100 as illustrated in FIG. 1, where golf ball manufacturers 100 use forward distribution channels 10-30 to convey golf balls to golf facilities 200 or golfers 300.

[0026] At the end of third stage 530, a golf ball can meet one of several fates. First, a golf ball can be discarded or become lost. A golf ball can become temporarily lost (e.g., within a golf course hazard), recovered, and re-used in life-cycle stage 535. However, a recovered hazard ball may exhibit poor performance due to its exposure to water, which can adversely affect the ball's compression, coefficient of restitution, weight, radius, and molecular structure. Moreover, hazard balls are also eventually discarded or lost. Such discarded or lost golf balls are handled, in a fourth stage 540, by a known waste management method such as depositing golf balls into a landfill. A golf ball's entry into fourth stage 540 can cause environmental concern because many golf balls contain thermoset polymers that do not degrade quickly. Moreover, for every discarded golf ball, golfers 300 or golf facilities 200 are likely to acquire a new golf ball produced by methods that deplete natural resources and emit greenhouse gases, as discussed above.

[0027] Alternatively, after the end of stage 530, stage 535 or stage 540, golf balls can advantageously enter into recycling stage 550. As illustrated in FIG. 3, which depicts the universal symbol of recycling, life-cycle stage 550 involves three distinct phases: collecting and processing the golf balls in phase 550a; recycling the golf balls in phase 550b; and selling recycled products in phase 550c. These phases 550a-550c generally use less natural resources and fossil fuel energy than stages 510 and 520, since in step 550b the core layer(s) and optionally at least some of the cover are saved and reused, as discussed in the Morgan patent. Phases 550a-550c produce balls that resemble newly manufactured golf balls.

[0028] Heretofore, there has been no effective method for the collection and processing of golf balls in phase 550a. More particularly, in phase 550a, there has been no effective channel for golfers 300 or golf facilities 200 to return worn or used golf balls back to manufacturers 100 for recycling. The present invention is advantageous because it provides reverse distribution channels 40-60 through which golf balls can be returned for recycling in phase 550b, wherein one recaptures as much of the used golf balls as possible. Thereby, golf facilities 200 and golfers 300 along with golf manufacturers 100 can effectively share in the environmental stewardship of golf balls. Because this shared environmental stewardship, also known as extended product responsibility, is facilitated by reverse distribution channels 40-60, the present invention represents a significant advance in the art of golf ball recycling.

[0029] In a first embodiment of the present invention, reverse distribution channels 40 and 50 are utilized by golfers 300 and golf facilities 200 to return used golf balls back to their original manufacturers 100. Generally, in reverse distribution channel 40, golfers 300 return used golf balls to golf facilities 200. Subsequently, as discussed in greater detail below, the golf facilities 200 sort the collected used golf balls according to the proper manufacturer 100. Next, in reverse distribution channel 50, golf facilities 200 return the sorted golf balls back to original manufacturers 100.

If you just can’t stop reading, check out the full published application HERE; and no, I did not make up the part about the kiosks. Check this out.

[0035] One way that individual golfers 300 can return used golf balls to original manufacturer 100 is through retail collecting stations, such as kiosks at golf facilities 200 or shopping malls or at selected locations in cities. Such kiosks would have an automatic sorter, such as the ones discussed above and described in the '592 patent. After the balls are sorted by original manufacturer and brands, and un-recyclable balls or balls belonging to other manufacturers may be rejected, the kiosks can provide the recyclers a receipt for the balls returned or a recycling credit. The amount of credit would depend on the quality of the brand and the quantity of balls returned. The kiosks may also provide the credit through emails or other electronic means. Alternatively, the kiosks may also carry newly manufactured or newly recycled balls and may exchange new balls for recycled balls. The kiosks may also represent points-of-sale for new golf balls with or without recycling.

I can’t wait to cash in a load of old beat-up balls for a Starbucks gift card! While my initial reaction is to shake my head and laugh, I have no doubt that the idea would work and undoubtedly would end up recycling tons of material that would otherwise be thrown away (or just roll back and forth in your trunk for years). For that reason I say, bring on the ball recycling kiosks (and install them right next to a swing training kiosk)!

David Dawsey – Keeping an Eye on Golf Ball Inventions

PS – click HERE to read more interesting golf ball patent posts

Comments