The Week of Pelz – Day 2 – Forget About Stimp Readings, What Is Your Course’s “Roll Quality”?

Yesterday we examined how Dave Pelz suggests we learn to read greens. Today let’s look at another of his recent inventions, namely a device to measure the “roll quality” of putting greens as disclosed in a patent application that published yesterday as US Pub. No.

The application explains:

[0004] 2. Description of the Related Art

[0005] In the area of golf course putting greens, green speeds (ball roll distance from a known starting energy level) are commonly measured using a variety of devices. These devices are exclusively focused on the length (distance) a golf ball travels over any surface. However, the ball roll distance, or green speed, is only one measure of the surface.

SUMMARY OF THE INVENTION

[0006] It is, therefore, an object of the present invention to provide a system for measuring roll quality of a putting green. The system includes a golf ball remotely communicating with a data processing unit composed of a computer software interface. The golf ball includes a golf ball outer surface with an interior cavity formed therein. An electronic system is positioned within the interior cavity. The electronic system is composed of an accelerometer, a microprocessor, a communications system and a battery. The electronic system allows a user to initiate a roll or putt of the golf ball on any surface and record data relating to roll quality thereby creating a roll data file.

.

.

.

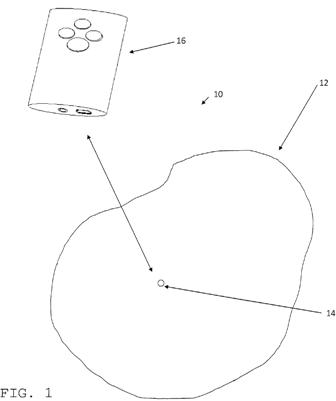

[0021] This invention relates to the measurement of how smoothly a golf ball 14 travels over any surface, thus producing a “roll quality” measurement of the surface. The present system 10 also relates to an easier form of green speed measurement for putting green surfaces on golf courses which regularly seek this information. The present system 10 also provides feedback to a practitioner of golf as to how solidly (with regards to side spin and energy transfer) he or she has struck a putt, and can be used as a learning aid when practicing putting.[0022] The golf ball 14 includes a conventional golf ball outer surface 18 with an interior cavity 20 formed therein. The golf ball 14 is a conventional “solid-core” golf ball with a cavity 20 formed therein. The electronic system 22 is inserted and potted into the interior cavity 20 and the golf ball 14 is reassembled, removing any seams caused through the formation of the cavity 20. The electronic system 22 weighs the same as the material that was removed in the creation of the cavity 20. In addition, it should be appreciated the golf ball will include surface dimples to maintain the familiarity to golfers.

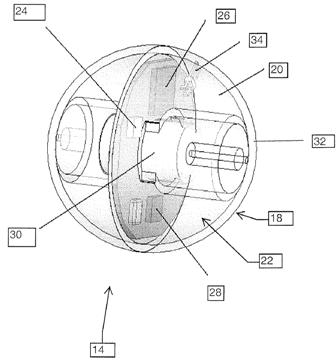

[0023] As briefly discussed above, the electronic system 22 is positioned within the interior cavity 20. The electronic system 22 is composed of an accelerometer 24, a microprocessor 26, a communications system 28 and battery 30 electrically interrelated for operation in accordance with the present invention. Briefly, the accelerometer 24 and communications system 28 are directly connected to the microprocessor 26 for the controlled transfer of data. The battery 30 is similarly linked to the microprocessor 26 for transmitting power to the remaining components of the electronic system 22. As will be discussed below in greater detail, these elements work together in gathering and processing information regarding the roll quality of a putting green.

[0024] The electronic system 22 allows a user to initiate a roll, or putt, of the present golf ball 14 on any surface and record data relating to the roll quality (thereby creating a “roll data file”). The accelerometer 24 generates raw data that is provided to the microprocessor 26 for processing thereof. The processed data is then ready and constitutes a “roll data file”. The ball’s communications system 28 transfers the “roll data file” from the golf ball 14 to the custom computer software interface 16 which analyzes the data and reports on the surface green speed and overall “roll quality” of the putting green (or surface) 12.

[0025] In accordance with a preferred embodiment, ultimate “roll quality” is determined considering a smoothness metric and a plane deviation metric. Referring to FIG. 3, the smoothness metric considers the deviation of the center 40 of the golf ball 14 from a plane 42 extending through center of the golf ball which is parallel to the putting green, or other surface 12, upon which the golf ball 14 is rolling. As is appreciated, a putting green is not flat and the plane 42 may therefore change to maintain its parallel relationship with the surface 12. Referring to FIG. 4, the plane deviation metric considers the deviation of the center 40 of the golf ball 14 from a plane 44 extending through the center of the golf ball 14 which is perpendicular to the surface 12 upon which the golf ball 14 is rolling. As is appreciated, a putting green is not flat and the plane 44 may therefore change to maintain its perpendicular relationship with the surface 12.

[0026] In accordance with a preferred embodiment, the smoothness metric is ultimately derived based upon the amplitude, that is, the distance which the golf ball moves up and down, of the deviation of the center 40 of the golf ball 14 from a plane 42 extending through center of the golf ball which is parallel to the putting green, or other surface 12, upon which the golf ball 14 is rolling and the frequency, that is, the rate at which the golf ball moves up and down, of the deviation of the center 40 of the golf ball 14 from a plane 42 extending through center of the golf ball which is parallel to the putting green, or other surface 12, upon which the golf ball 14 is rolling. The smoothness metric is also determined based upon the deceleration of the golf ball at different time intervals and for different interval lengths as it rolls along the putting green surface. The calculations are performed with golf balls rolling at various speeds, for example, 6, 5, and 4 feet per second.

[0027] With regard to the plane deviation metric, this metric is generated based upon the sum of rotation plane deviations, that is, the number of times the golf ball moves laterally right or left such center of the golf ball deviates laterally from a plane 44 extending through the center of the golf ball 14 which is perpendicular to the surface 12 upon which the golf ball 14 is rolling. As with the smoothness metric, this value is derived based upon a plurality of samples, for example, 100 samples, at different speeds, for example, 3, 2, and 1 feet per second. The smoothness metric and plane deviation metric are analyzed for the production of a final “Roll Quality Value.”[0028] In accordance with a preferred embodiment of the present invention, the data, that is, the “roll data file” is collected and stored within the golf ball 14 for a spe

cified time period during the roll, then the “roll data file” is transmitted to the custom computer software interface 16. In accordance with a preferred embodiment, the golf ball 14 will hold at least 100 independent rolls and hold that data until the golf ball is downloaded onto a computer for storage and analysis. However, it is appreciated other embodiments could transmit data continuously (in real time) during the roll.[0029] In accordance with a preferred embodiment, the golf ball 14 is a solid core two piece USGA (United States Golf Association) approved golf ball of standard size and weight specifications, with precision cavity(ies) 20 milled to hold the components of the electronic system, that is, the accelerometer 24, microprocessor 26, communications system 28 and battery 30, to create a final configuration which has the standard size and weight of a USGA approved golf ball. It is appreciated special materials could be used within the golf ball 14 to duplicate the weight and balance characteristics of a standard golf ball, and the outer surface of the golf ball 14 could be covered with various sized and shaped dimples to duplicate the various geometries of existing or future dimple configurations, or could be dimple free.

[0030] In accordance with a preferred embodiment, the golf ball 14 is a traditional size (that is, 1.68” outer diameter in accordance with USGA rules) and includes a uniform interior shell material 32 shaped and dimensioned to house the electronic system thereof, allowing for the monitoring and collection of data relating to the surface under study. The accelerometer is preferably a 3-axis accelerometer 24. The microprocessor 26 is a standard processor capable of handling the computation requirements of the present invention. The communications system 28 is preferably comprised of an RF transmitter 28 (for example, and in accordance with a preferred embodiment of the present invention, a 2.4 GHz RF Transmitter). With regard to the battery 30, it is preferably a rechargeable NiMH battery with charging capability being provided via the provision of charging contacts 34 extending between the interior cavity 20 and the exterior surface of the golf ball 14 (or for example by inductive charging from an external charging unit, without the use of any surface contacts). In accordance with a preferred embodiment, the various components of the electronic system 22 are press fit within the cavity 20 and the electronic system 22 is potted in place, that is, the electronic system is filled with a solid compound for resistance to shock, vibration, moisture and corrosive agents. A custom computer program loaded on the custom computer software interface 16 analyzes and interprets the roll data.

[0031] By accurately measuring the “roll quality” of balls on various putting greens and surfaces (as their rolls are misdirected, disturbed, bounced and/or deflected off-line by imperfections on the measured greens and surfaces, as compared to what their “perfect” roll trajectories would have been on a “perfectly smooth surface”), this invention will allow a metric to be developed to describe and compare the roll quality of various putting greens and surfaces around the golfing world. In the area of golf course putting greens, green speeds (ball roll distance from a known starting energy level) are commonly measured using a variety of devices. These devices are exclusively focused on the length (distance) a golf ball travels over any surface. However, the ball roll distance, or green speed, is only one measure of the surface. This invention measures the smoothness of roll on the green by using high-tech instruments embedded within the test golf ball 14 which obtain data regarding surface roll smoothness details along the path on which the golf ball travels. When imported into the computer software interface 16, the path of the golf ball can be viewed and analyzed. The overall smoothness and pureness of the golf ball’s roll is determined by comparing the balls actual roll direction and motion (obtained by evaluating the ball’s actual three axis accelerometer data) at several different time intervals and rolling speeds, to the theoretically pure motion it would have experienced if the surface upon which it rolled would have been perfectly smooth. The green speed of any putting surface can be determined as a result of knowing the rate of deceleration of the golf ball across the surface.

Ugh, something else for Johnny Miller to fixate on!

Dave Dawsey – The Golf Patent Lawyer

PS – check out some of Mr. Pelz’s issued patents HERE