The Technology Behind the Hype: 2014 RZN Golf Balls with Speedlock Core Technology

Most golf geeks are well aware of last week’s media schmooze fest put on by Nike Golf (if not, read about it here and here). Apparently my invitation got lost in the mail; probably smart given my distrust of anything associated with over the top marketing. I prefer facts, technical data, and generally boring “spin-free” information; you know, like the information found in patent applications.

Most of the lucky invitees seemed to be most impressed with their 2014 RZN golf balls with Speedlock Core Technology. I have to admit, the pictures are pretty intriguing.

Recently a Nike Golf patent application published as US Pub. No. A golf ball having a golf ball core, one or more intermediate layers and a cover layer is disclosed. The golf ball core may include an inner core having radial appendages. The radial appendages may protrude from the inner core in a spherically symmetrical pattern. The radial appendages may be formed from the same material as the inner core. The one or more intermediate layers may surround the inner core and fill the voids between the radial appendages.

The application appears to be the first of many directed to the Speedlock Core Technology concept.

The application goes on to explain:

[0031] The golf ball core of the disclosure may include an inner core having radial appendages. The inner core may be any symmetric shape. The inner core may have a spherical shape. The radial appendages may extend from the inner core in a spherically symmetrical pattern. The number of radial appendages extending from the inner core may be selected based on a variety of factors. For example, the numbers of radial appendages may be selected based on the desired play characteristics of the finished golf ball. Any number of radial appendages may extend from the inner core so long as the radial appendages are arranged in a spherically symmetric pattern. At a minimum, the golf ball core may have six radial appendages.

.

.

.

[0033] Embodiments of the disclosure may include provisions for controlling the transfer of force from the impact of a golf club from the cover layer to the inner core. Some of the provisions may enhance the transfer of force from the cover layer to the inner core. Other provisions may limit the transfer of force from the cover layer to the inner core. Some embodiments of the golf ball core can be shaped or designed to achieve the force transfer. The golf ball cores of the disclosure may have radial appendages to assist with the transfer of force from the cover layer to the inner core. The radial appendages of the golf ball can be arranges in a spherically symmetric pattern.[0034] Embodiments of the radial appendages include radial appendages that are also resilient members of the golf ball core. Resilience can be defined as the ability to return to original form or position after being bent, compressed or stretched. Stated another way, resilience is the ability of a material to absorb energy when it is deformed elastically, and release that energy upon unloading. In some embodiments, the radial appendages are resilient to the force of an impact from a golf club.

.

.

.

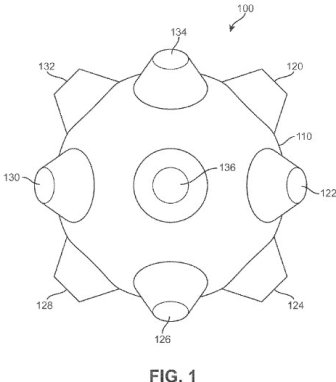

[0037] The shape or design of the radial appendages may be selected based on a variety of factors. The size and shape of the radial appendages may be selected to provide a finished golf ball with desired play characteristics. For example, the length of each radial appendage may vary based on the size the inner core. Further, wider radial appendages may be formed to provide the finished golf ball with a firmer feel. In some embodiments, thinner radial appendages may be formed to provide the finished golf ball with a softer feel. In addition, the golf ball core may contain a combination of radial appendages having different shapes and sizes.[0038] FIG. 1 shows a golf ball core 100 having an inner core 110 and one or more radial appendage. In the embodiment shown in FIG. 1, golf ball 100 includes first radial appendage 120, second radial appendage 122, third radial appendage 124, fourth radial appendage 126, fifth radial appendage 128, sixth radial appendage 130, seventh radial appendage 132, eight radial appendage 134, and ninth radial appendage 136. Further, the radial appendages and inner core may be made from the same material. The radial appendages and inner core may be one piece.

[0039] As shown in FIG. 1, the radial appendages are arranged in a spherically symmetric pattern extending from inner core 110. Each radial appendage that extends from inner core 110 may have a corresponding appendage that extends from inner core 110 on the direct opposite side of inner core 110. For example, radial appendage 120 extends in one direction from inner core 110 on one side of inner core 110 and radial appendage 128 extends in the opposite direction from inner core 110 on the direct opposite side of inner core 110. In addition, the radial appendages may be spaced an equal distance from each other on inner core 110.

.

.

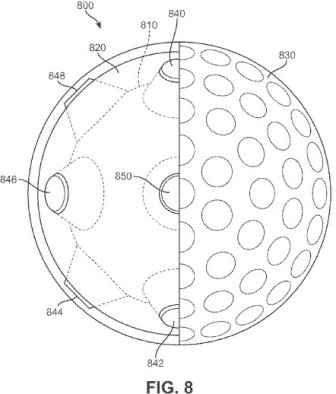

.[0059] FIG. 8, shows an embodiment of finished golf ball 800 having golf ball core 810, intermediate layer 820, and cover layer 830. The cover layer 830 has been cut out to reveal the interior of finished golf ball 800. Golf ball core 810 having first radial appendage 840, second radial appendage 842, third radial appendage 844, fourth radial appendage 846, fifth radial appendage 848 and sixth radial appendage 850 can be seen in FIG. 8. Intermediate layer 820 fills in the spaces between the radial appendages. However, the radial appendages extend beyond the outer surface of intermediate layer 820. For example, the cut out reveals that at least third radial appendage 844 and fifth radial appendage 848 abut, or are in contact with, the cover layer. In this embodiment, third radial appendage 844 and fifth radial appendage 848 extend into the cover layer.

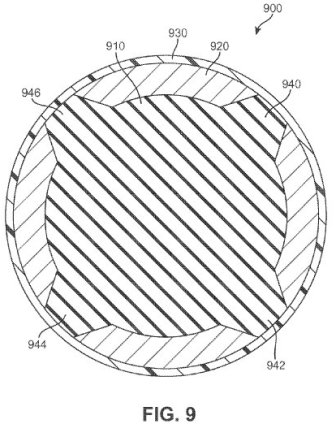

[0060] FIG. 9 shows a cross-section of an embodiment of a finished golf ball 900. The cross-section reveals golf ball core 910 having first radial appendage 940, second radial appendage 942, third radial appendage 944 and fourth radial appendage 946, as well as intermedi

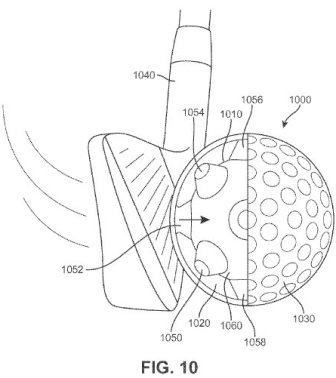

ate layer 920 and cover layer 930. The cross-section of finished golf ball 900 reveals a spherically symmetric golf ball core. In addition, first radial appendage 940, second radial appendage 942, third radial appendage 944 and fourth radial appendage 946 all abut, or are in contact with, cover layer 930. In embodiments where the radial appendages abut the cover layer, the impact of the golf club striking the golf ball may be transferred through the cover layer to those radial appendages abutting the portion of the cover layer being struck by the golf club face, and then through the radial appendage to the inner core.[0061] FIG. 10 shows finished golf ball 1000 being struck by golf club 1040. Finished golf ball 1000 includes golf ball core 1010 having inner core 1060, first radial appendage 1050, second radial appendage 1052, third radial appendage 1054, fourth radial appendage 1056, and fifth radial appendage 1058, as well as intermediate layer 1020 and cover layer 1030. At least second radial appendage 1052, fourth radial appendage 1056 and fifth radial appendage 1058 of the golf ball core 1010 abut, or are in direct contact with, cover layer 1030.

[0062] When golf club 1040 strikes finished golf ball 1000, a portion of cover layer 1030 and the radial appendages in contact with that portion of cover layer 1030, for example second radial appendage 1052, may be compressed upon impact with the golf club. The impact of golf club 1040 may be transferred through the cover layer to the radial appendages in contact with that portion of the cover, for example second radial appendage 1052. Further, the force of the impact may be transferred through second radial appendage 1052 into inner core 1060 of the golf ball core 1010.

[0063] In addition to cover layer 1030 and golf ball core 1010, intermediate layer 1020 of finished golf ball 1000 also may be compressed when struck by golf club 1040. As discussed above, the one or more intermediate layers may have a hardness that is different from the hardness of the golf ball core. In some embodiments, intermediate layer 1020 may have a hardness that is less than the hardness of the golf ball core 1010. The softer intermediate layer 1020 may provide for a golf ball with a better feel and control when struck with a golf club.

[0064] The finished golf ball of the disclosure having a golf ball core with radial appendages may provide for a finished golf ball that has a better feel, without loss of drive or long iron distance. In addition, the finished golf balls of the disclosure may provide for greater control or spin of the golf ball when struck with shorter irons. Further, the finished golf balls of the disclosure may provide for better sound characteristics when struck with a golf club.

[0065] In addition to the improved play characteristics described above, the golf balls of the disclosure also may exhibit improved construction and durability. Conventional golf balls may be made with a core, a cover layer and a mantle layer between the core and cover layer. Typically, the layers of the golf ball may be held together through some type of adhesion. The adhesion may be an interaction between the materials that form the layers. The adhesion may also be an adhesive coating between the layers. In either case, adhesion between golf ball components may sometimes be problematic. For example, if the layers of a golf ball become dissociated with each other, such as delamination with adjacent layers, buckling of the material, fracturing or cracking of the material, etc., the ball would “deaden”. Poor adhesion between the golf ball layers may result in layer dissociation.

[0066] The finished golf ball of the disclosure may exhibit improved durability. The finished golf ball of the disclosure may have a conventional method to adhere the intermediate layers to golf ball core. For example, the finished golf ball of the disclosure may include a chemical means for adhering adjoining layers. The chemical means may be an interaction between the materials of the golf ball core and the intermediate layers, or it may be an adhesion layer between the two components.

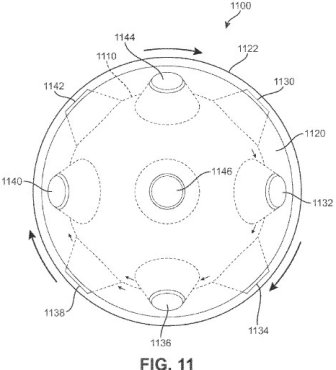

[0067] However, the finished golf ball of the disclosure may also have a mechanical means for the changing the durability of the finished golf ball. As shown the embodiment of FIG. 11, first radial appendage 1130, second radial appendage 1132, third radial appendage 1134, fourth radial appendage 1136, fifth radial appendage 1138, sixth radial appendage 1140, seventh radial appendage 1142, eight radial appendage 1144, and ninth radial appendage 1146 of finished golf ball 1100 extend from golf ball core 1110 through intermediate layer 1120. By extending through the intermediate layer, the radial appendages also may hold the intermediate layer in place mechanically. Although radial appendages in the form of tapered columns are show in FIG. 11, radial appendages of any size or shape will have a similar effect on the intermediate layers.

[0068] When a force is applied to the golf ball, the radial appendages may provide a mechanical resistance to the one or more intermediate layers moving or shifting, thereby maintaining the durability of the finished golf ball. For example, when a golf ball is spinning at a high rate (shown by the arrows rotating around finished golf ball 1100), the force of the spin may apply a stress to the adhesion between the golf ball core and the intermediate layer. The radial appendages may provide a better resistance to such a stress. This improved resistance to adhesion stress may provide for a more durable golf ball. Therefore, the golf ball of this disclosure may exhibit improved durability without sacrificing driver performance or golf ball feel.

[0069] Embodiments of the finished golf ball may be both statically and dynamically balanced. Static balance can be defined as the ability to remain at rest in any position when placed on a level surface. Dynamic balance can be defined as the ability of the axis about which a rotating body is forced to rotate to remain parallel to a principal axis of inertia. In other words, dynamic balance occurs when the mass of the body (golf ball) is evenly distributed about its rotating center line. Embodiments of the golf ball may be tuned or modified to balance the golf ball both statically and dynamically.

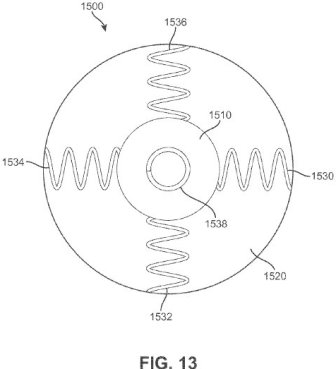

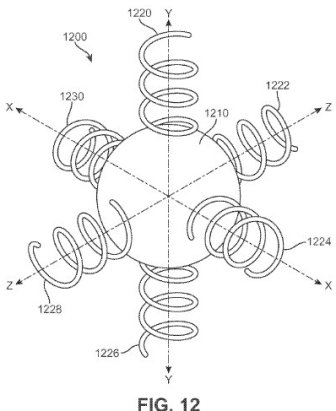

[0070] While the radial appendages of the golf ball core may be the form of columns, as discussed in some of the embodiments above, in other embodiments of the golf ball, the radial appendages also may take the form of any suitable shape. In some embodiments, the radial appendages may be in the shape of springs or coils.

[0071] As stated above, the shape or size of the radial appendages in the shape of springs or coils may be selected based on a variety of factors. The size and shape of the radial appendages may be selected to provide a finished golf ball with desired play characteristics. In addition, the length of each ra

dial appendage may vary based on the size the inner core. The size of each radial appendage may depend upon the type of appendage chosen (spring, coil or column) and the material used to form the radial appendages. In addition, the golf ball core may contain a combination of radial appendages having different shapes and sizes.[0072] In addition, the springs or coils may have any suitable stiffness or spring constant. In some embodiments, the stiffness of the radial appendage may be low. In those embodiments where the radial appendage has a low stiffness, the finished golf ball may have a softer feel. In addition, the finished golf ball having low stiffness radial appendages also may exhibit better control when struck with short irons and wedges. In some embodiments, the stiffness of the radial appendage may be high. In those embodiments where the radial appendage has a high stiffness, the finished golf may have a firmer feel. The stiffness of each radial appendage may depend on the material used to form the radial appendage. Further, the stiffness of each radial appendage may depend on the size and shape of each radial appendage. The stiffness of the radial appendages may be selected based on the desired play characteristics of the finished golf ball.

.

.

.

[0086] As discussed above, the finished golf ball of the disclosure having a golf ball core with radial appendages may provide for a finished golf ball that has a better feel, without loss of drive or long iron distance. In addition, the finished golf balls of the disclosure may provide for greater control or spin of the golf ball when struck with shorter irons. Further, the finished golf balls of the disclosure may provide for better sound characteristics when struck with a golf club.[0087] In addition to the improved play characteristics described above, the golf balls of the disclosure also may exhibit improved construction and durability. The finished golf ball of the disclosure may have a mechanical means for the changing the durability of the finished golf ball. By extending through the intermediate layer, the radial appendages also may hold the intermediate layer in place mechanically.

[0088] When a force is applied to the golf ball, the radial appendages may provide a mechanical resistance to the one or more intermediate layers moving or shifting, thereby maintaining the durability of the finished golf ball. This improved resistance to adhesion stress may provide for a more durable golf ball. Therefore, the golf ball of this disclosure may exhibit improved durability without sacrificing driver performance or golf ball feel.

Cool stuff (probably even cooler on a plane to Vegas to play golf and meet Rory)!

David Dawsey – Keeping an Eye on Golf Ball Patent Applications

PS – Follow me on Twitter (@GolfPatents) to receive the latest golf patent updates