The Rest of the Story re Callaway’s Aerodynamic Hosel Patents

It is hard to believe it has been a year since I covered three unique hosel design patents awarded to Callaway Golf (here, here, and here). At the time I commented that it is easy to dismiss one or two wacky design patents as just something dreamt up in R&D that is unlikely to ever see the light of day in an actual product; but by the time that a third variation appears in a design patent one has to start thinking “they may be serious about bringing some of these variations to market.” One of the posts concluded with the thought that there must be some performance benefit associated with these new hosel designs, otherwise it is hard to imagine a Tour player saying “boy that fits my eye, give me one of those.” I can’t wait to learn “the rest of the story.” Well, today we learn the rest of the story.

The patent goes on to explain:

2. Description of the Related Art

Technical innovation in the size, structure, configuration, material, construction, and performance of golf clubs has resulted in a variety of new products. The contribution of the hosel to overall drag of a club head can be significant, but it has largely been ignored by manufacturers and innovators even though the advent of adjustable hosel configurations with increased dimensions has resulted in a larger contribution to club head drag for some club head models. For low drag head shapes the contribution of the hosel becomes more important.

The hosel of a golf club head is the connection between the shaft and the head. It is typically circular in cross-section with a diameter that is larger than the shaft. Both tapered and constant cross-section approaches can be used. The hosel is a relatively small subcomponent of a golf club head, but it essentially travels at the same high speed as the head and is usually has a very aerodynamically inefficient shape. In addition, it operates in a flow field that is heavily influenced by larger club heads, particularly in drivers.

Although the prior art has disclosed many variations of golf club heads, including a variation disclosed in U.S. Pat. No. 1,587,758 (entitled “Golf Club”) to Charavay, the prior art has failed to provide a club head with a hosel configuration that does not interfere with or have a negative effect on airflow during a swing.

.

.

.

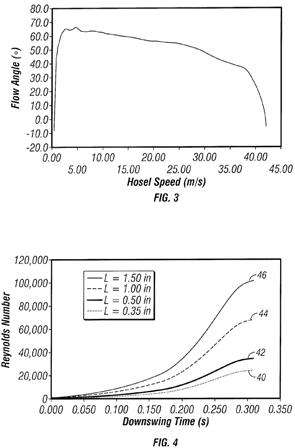

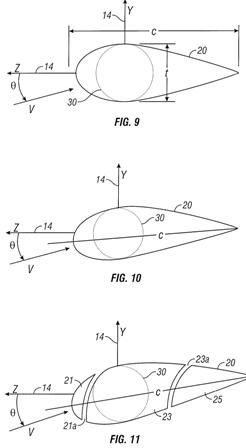

FIG. 3 shows the variation of the flow angle theta with flow velocity during a typical downswing with a head speed at impact of 100 mph. At the very earliest stages of the downswing, flow speeds are very low as the flow angle increases markedly. This is followed by a period of increasing speed and a near linear decline in flow angle. Just prior to impact, at the very highest flow speeds there is a rapid drop in flow angle. Flow about the hosel 20 is also heavily influenced by the adjacent head 10, which accelerates flow velocities and affects flow directions. This leads to a much higher drag than would be experienced by a hosel 20 alone on the end of a shaft 40 subjected to a standard swing profile.

.

.

.

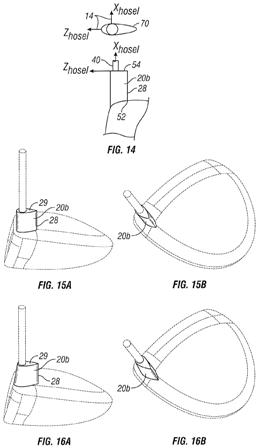

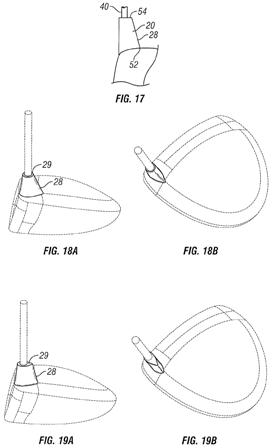

FIG. 5 illustrates the difference between Reynolds Numbers at 100 mph for a circular cross-section hosel 20a and one configuration of an airfoil cross-section hosel 20b having the same thickness. The present invention is not limited to this configuration. FIG. 6 demonstrates how an airfoil cross-section hosel 20b has less than one fifth of the drag of a circle cross-section hosel 20a of the same thickness at speeds of 100 to 160 mph.Drag and Energy Loss

Aerodynamic drag of the hosel 20 is a factor in overall club drag, and becomes more significant as drag of the head 10 is reduced. As with the head 10, drag of the hosel 20 varies significantly over the time of the downswing. Large changes are induced by significant changes in orientation. Overall drag force increases with the square of velocity.

Energy dissipated by drag is meaningful in that the goal of the downswing is to impart the maximum amount of energy to the club head, and hence the ball. Furthermore, this energy is supplied by a system with limited output: the golfer. Any energy lost to drag is not available at impact and degrades performance. In general, energy dissipated due to drag, or power loss, goes with the cube of velocity. This parameter is useful because it provides a weighting scheme, giving more weight to the higher velocity portions of the swing. Furthermore, by integrating power loss over the period of the downswing, a total energy loss can be computed, resulti

ng in a single FIGURE of merit with which to compare various drag reduction methods. Different swings can also be compared with this approach.

Interesting stuff! Can’t wait for one to reach the market (and hear the marketing spin).

Dave Dawsey – Keeping an Eye on Innovative Golf Club Patents