The Perfect Product Name for this Golf Ball – Russian Roulette

The new Russian Roulette golf ball by Nike Golf; a nice politically incorrect name, something “The Donald” would come up with, not Nike Golf. Nonetheless, a golf ball patent issued this week that should be titled “Russian roulette golf ball,” but is actually titled “golf ball having a cover layer with two different hardness values.” The patent is USPN 9067105, which describes the invention as:

“The disclosure relates to a golf ball having a cover layer including a first cover layer portion having one hardness values and a second cover layer portion having a second hardness value.”

Sure, it is easy to position the ball for impact exactly how you desire when you are on the tee box, the game of chance occurs later, provided you are going to play by the rules and not roll the ball to suit the situation.

The patent explains:

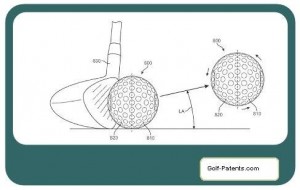

A golf ball having a cover layer with two cover layer portions with different hardness allows the golfer to choose the side of the golf ball the golfer desires to strike with a golf club. In some instances, a golfer may choose to hit the cover layer portion that has a greater hardness value when driving the golf ball off a tee or when using fairway woods or long-irons. Striking the harder cover layer portion with a wood or long-iron may provide the distance a golfer would expect when using such clubs. Further, striking the harder cover layer portion of the golf ball may also provide less backspin, which will assist with maintaining the driving distance.

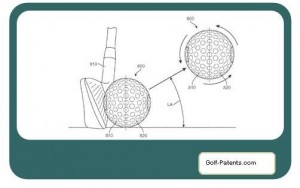

In other instances, a golfer may choose to strike the softer cover layer portion with a short iron or wedge, or even a putter. Striking the softer cover layer portion may provide greater backspin. Further, striking the softer cover layer portion may also provide better control of the golf ball.

Embodiments of the disclosure include a golf ball having a cover layer comprising a first cover layer portion having a first hardness and a second cover layer portion having a second hardness. The first cover layer portion and second cover layer portion may be discernible to a golfer. In some embodiments, the first cover layer portion may be visibly discernible from the second cover layer portion of the golf ball cover layer. In other embodiments, the first cover layer portion may be tactilely discernible from the second cover layer portion. In further embodiments, the first cover layer portion may be both visibly and tactilely discernible from the second cover layer portion.

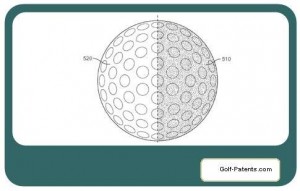

In FIG. 5, first cover layer portion 510 of finished golf ball 500 is visually distinguished from second cover layer portion 520. Each cover layer portion may have a different cover. For example, first cover layer portion 510 may have a grey color while second cover layer portion 520 may have a white color.

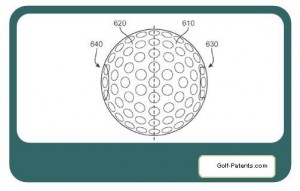

In other embodiments, the finished golf ball may have a stamp or mark noting a first cover layer portion and a second cover layer portion. As seen in FIG. 6, golf ball 600 has a first cover layer portion 610 and a second cover layer portion 620. Golf ball 600 may be a typical white color with a stamp or mark denoting each cover layer portion. The stamp or mark may be any suitable shape. In some embodiments, the stamps may be different shapes.

In FIG. 6, first cover layer portion 610 may be marked with rectangular stamp 630. Second cover layer portion 620 may be marked with circular stamp 640. In one embodiment, the circular stamp may mark the harder of the cover layer portions and the rectangular stamp may mark the softer of the cover layer portions. The shape or design of the stamp marking each cover layer portion can be any suitable design or shape to denote the cover layer portion of the ball being struck by a golf club.

Further, the color of the stamp can be any suitable color the manufacturer chooses. In some embodiments, the stamps may be the same color. In other embodiments, the stamps may be different colors.

The cover layer portions may be further distinguished in both a visibly and a tactilely manner. Typically, golf ball cover layers comprising a plurality of dimples in any pattern. The plurality of dimples may generally be arranged on the cover layer in any pattern, as may be known in the art of golf balls. Various known dimple packing patterns are known in the art. Dimples may generally be of any shape, such as circular, triangular, or multi-sided shapes. Further, dimples may be of uniform shape and size, or the dimple pattern may be of two or more different types of dimples having (for example) different sizes or different shapes. In some embodiments, the cover layer may have two different dimple patterns denoting the two cover layer portions.

.

.

.

The golf ball of the present disclosure may exhibit similar characteristics when struck with a wood or long-iron on the harder face of the cover layer. The golf ball may have an initial velocity between about 136 to about 142 mph, a launch angle between about 8.degree. and about 12.degree., and a backspin rate of between about 2400 and about 3200 rpms.

In contrast to FIG. 8, FIG. 9 illustrates short iron or wedge 910 striking golf ball 800 on softer cover layer portion 810. In comparison to being struck with a wood on larder cover layer portion 820, when struck with a short iron or wedge on the softer cover layer portion, golf ball 800 has a higher launch angle and is subject to greater backspin.

What do you think, any chance this golf ball ever sees a pro shop? Hell no!

Dave Dawsey – The Golf Invention Attorney

PS – follow me on Twitter (@GolfPatents) and sign-up HERE to receive posts via email.

PPS – If you like what we are doing, please considering helping us out and make your online gear purchases through our Amazon affiliate link. Every little purchase helps us keep the site up and running! Thanks.