Kim Adds Some Bling to Golf Clubs

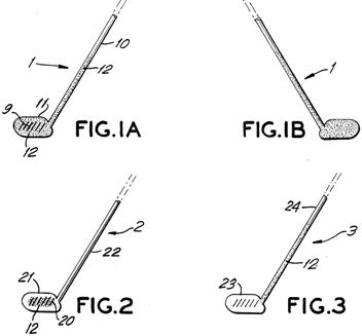

Dong Kim that is; surely you didn’t think I was referring to Anthony Kim. Dong is the inventor listed on an old patent that I recently came across and thought “… kind of interesting.” Dong’s patent is USPN 4,951,953 and is directed to a diamond coating for golf clubs. The patent explains:

In order to provide a golf club having longer flying distance and greater directional accuracy characteristics, three requirements should be met.

First, at the impact of the club head against a ball, the power being generated by the club head should be transferred as completely as possible to the ball to result in an increased flying distance. Generally, a greater power transfer can be achieved by constructing the ball-striking face of the club head with a material having a high hardness or a high Young’s Modulus. Therefore, steel and carbon fiber composites perform well as materials for constructing club heads.

Second, the restitution time of the club shaft should be as short as possible to achieve accurate timing for releasing power on the down-swing of the club. Generally, the greater the Young’s Modulus of the materials used for constructing the shaft, the greater the restitution speed (or the shorter the restitution time) of the shaft will be. In other words, as the Young’s Modulus of the shaft increases, the restitution time of the club becomes closer to zero. Since carbon fiber possesses less than one-fourth the density of steel, but approximately same Young’s Modulus in magnitude (see Table 1 below), carbon fiber should theoretically provide a better club shaft, having shorter restitution times and lower material weight as compared with conventional steel shafts.

Third, the torque (torsion) of the club shaft should be as low as possible to result in greater directional accuracy upon impact between the club head and the ball. This is a serious problem in the design of golf clubs. Particularly, the thinner end of shaft which is attached to the club head is prone to torsion by the relatively heavy club head on down swing and particularly at impact with the ball. As discussed above, an unfortunate drawback of recent carbon shafts is that they often create worse torque problems than conventional steel shafts.

The present invention addresses all of these three requirements. According to the present invention, these requirements are met by coating a golf club (including the head and a substantial portion of the shaft) with either materials having a high Young’s Modulus or with high Young’s Modulus materials in a composite form with other materials as matrices. The coating of the club face with the high Young’s Modulus materials or composites thereof results in improved rebound (impact) characteristics. Moreover, in preferred embodiments where both the club head and a substantial portion of the shaft are coated, the present invention also provides for dramatic improvements in the torque resistance properties of the thinner part of shaft end which is attached to the club head.

.

.

.

Useful materials for coating both heads and shafts of golf clubs according to the present invention are those materials which possess a high Young’s Modulus. However, when considering the benefits of materials having high rigidity or high Young’s Modulus for use according to the invention, the density of the material should also be considered. Such a relationship is expressed by Y/D in Table 1. For example, there is only a small difference in Young’s Modulus between steel and carbon fiber as shown in Table 1. However, since it possesses a lower density than does steel, carbon fiber provides a much higher rigidity than does steel on an equivalent weight basis. According to Table 1, carbon fiber is more rigid than steel by 4.5 times.

.

.

.

Among these potential materials, diamonds are the hardest material presently known to man and possesses the highest Young’s Modulus. Therefore, diamonds are most preferred materials for coatings in accordance with this invention. Since diamonds also possess low specific gravity as compared with metals such as steel, even a one mil thick diamond coating provides a rigidity roughly similar to that of 12 mil steel.Although it would be ideal to provide a coating of pure diamond on a golf club in accordance with the invention to increase rigidity to a maximum level, the technology for providing diamond coatings in general has long been difficult for both economic as well as technical reasons. Moreover, because of the superior physical and chemical properties which make diamond materials preferred for the present invention, diamonds are also difficult materials to apply on a substrate in the form of coating by either physical or chemical process. For example, processes recently reviewed in Chemical and Engineering News, May 15, 1989, pages 24-39 (Bachmann and Messler) for providing an ultra-thin film coating (on the order of 0.1 micron) of pure diamond are so costly and difficult to build up to an effective film thickness that resulting products may become commercially non-competitive (although a golf club coated in accordance with such technology would be within the scope of the present invention).

Another difficulty of using pure diamond is the cost of the material itself. Although synthetic diamonds are reasonably priced as compared to natural diamonds, and are very useful for this invention, they are still far more expensive than other lower priced ceramics and metals. If it is necessary or desirable to save on the cost of coating material, the diamond component could, of course, be replaced by other desirable high Young’s Modulus materials disclosed in accordance with the invention.

In order to make preferred embodiments of the invention economically as well as technically feasible, it has been found that high Young’s Modulus coating materials such as diamond can be conveniently applied in the form of a composite with other materials such as nickel as matrices One such process is called electroless “composite diamond coating” technique. Such techniques are now well known to those skilled in the art electroless metal plating. Examples of presently known “electroless” composite diamond coating techniques can be found in U.S. Pat. Nos. 4,547,407 and Re 29,285, which are incorporated herein by reference.

Here is an interesting bit of information from the patent:

Since the impact front face of a steel (“wood”) club head may be, for example, approximately 1/8 inch thick, the improvement in head rigidity is about 9.6% over that of a steel club head which is not coated by diamond. However, because the wall thickness of an, e.g. steel shaft is thinner than the front impact face of the club head by approximately one-third, the same 1 mil coating of diamond on a steel shaft will result in an improvement of rigidity of over 3 times that which was obtained for the coated club head.

Since Dong’s patent is from 1990, I got a chuckle out of the following paragraph:

However, as is well-recognized by golf enthusiasts, the new light-weight, carbon-fiber shafts (including those incorporating expensive and specialized metals such as boron) often exhibit torque or twisting of the club head relative to the shaft on down-swing and particularly at ball contact. Thus, although the carbon-fiber shaft clubs offer some weight and design configuration advantages over steel shaft clubs, the carbon fiber shaft clubs are generally recognized as being somewhat difficult to control. As is well-known, the inability to control the club head leads to poor accuracy and diminished flying distance.

See, it wasn’t that long ago that graphite shafts were the scary new technology!

You have to admit that a dia

mond coated club would make a statement.

Dave Dawsey – Looking for that Golf Patent that is a Diamond in the Rough

PS – click HERE to check out other golf club intellectual property posts