Is This Club Manufacturing Method Crazy or Beautifully Genius?

A patent issued this week directed to a golf club manufacturing technique that is rather interesting. The patent is USPN 7,670,532 titled “Golf Club Head and Method of Making the Same,” and describes the invention as:

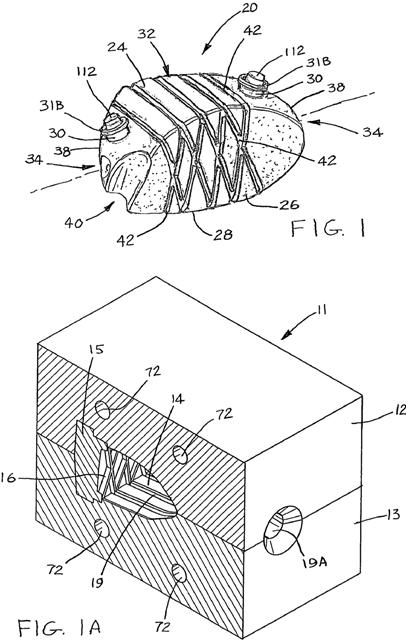

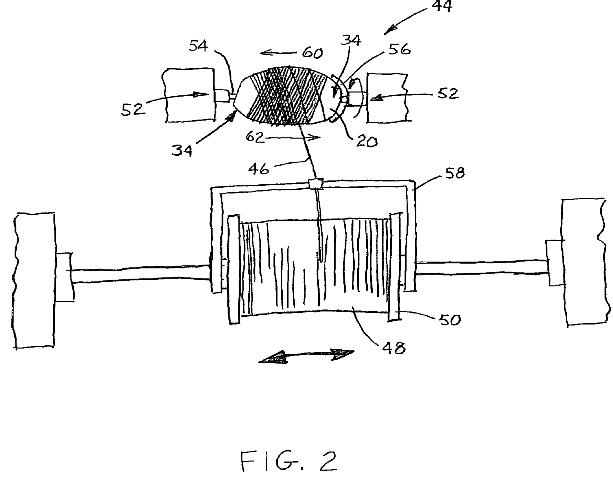

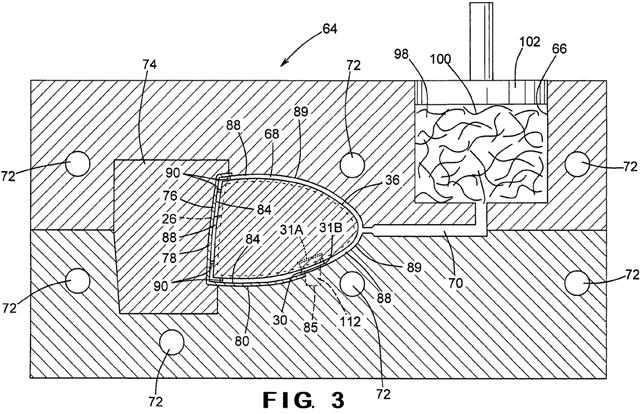

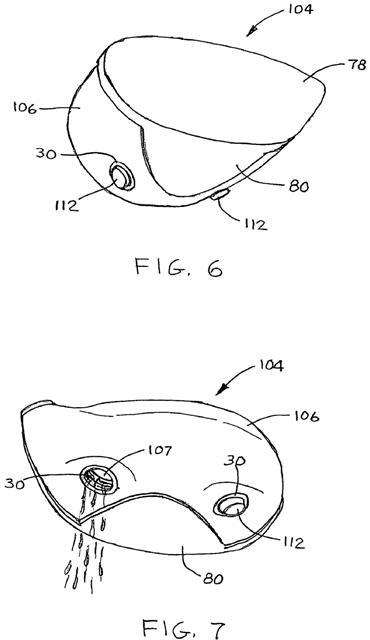

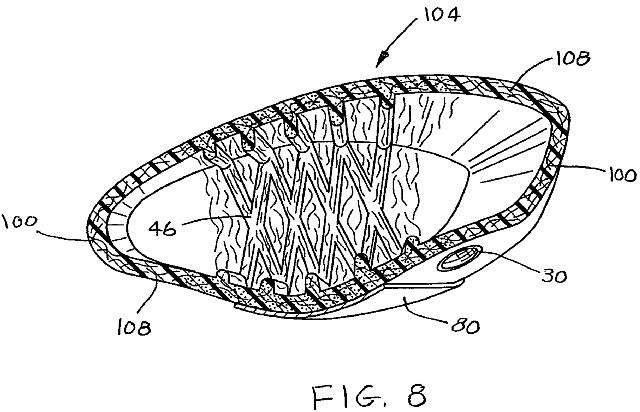

A golf club head and a method of making a golf club head are disclosed. The method provides for winding a single continuous filament multiple times about a soluble core. The wound core is located in a mold and pressure coated with a pure or non-continuous fiber filled resin. The resin is allowed to cure to form a filament and resin shell about the core. The soluble core is removed leaving the continuous filament in the shell.

The patent explains:

It is an object of the present invention to overcome the disadvantages inherent to the above described and traditional methods and resulting structures of club heads, and to provide a new head design as well as a new method of manufacturing such head.

Thus, one of the more specific objects of the invention is to provide a manufacturing method enabling a more efficient new head structure to be obtained, especially as regards distribution of mass, durability, and finishing quality. The method according to the invention is particularly adapted to the large scale production of elements requiring a minimum number of operations to produce what might be considered a complex yet highly advantageous golf club head.

Thus, according to the invention, a method of manufacturing a golf club is disclosed. The method is comprised of the following steps. A single continuous filament is wound multiple times about a soluble core. The wound core is then located in a mold. The wound core is then pressure coated with a resin in the mold. The resin disperses among the filament windings. The resin is allowed to cure and form a filament and resin shell about the core. The soluble core is then removed from the shell while the continuous filament is retained within the shell.

The shell has an inside surface and an outside surface. The inside surface defines a substantially hollow interior portion and the inside surface has a plurality of ribs that extend into the interior portion. The ribs and the shell are substantially comprised of the resin and the single continuous filament located within the resin.

Check out the drawings, which illustrate the process:

So, it that crazy or genius?

Dave Dawsey – Monitoring Golf Club Design Intellectual Property