I Can Already See the Advertisements Proclaiming “#1 Lubricant in Golf”

Which manufacturer do you think came up with this lubricated design?

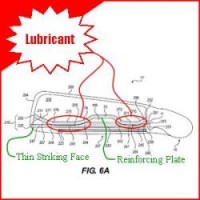

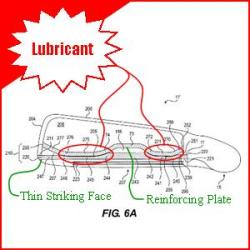

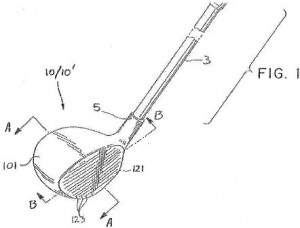

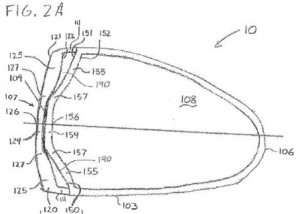

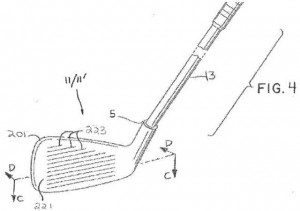

The drawing comes from a patent application that published this week as US Pub. No. 20150165280 titled “Golf Club Head,” which describes the invention as:

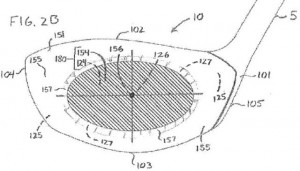

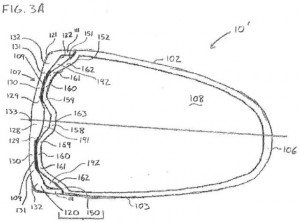

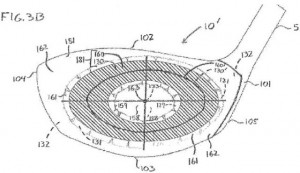

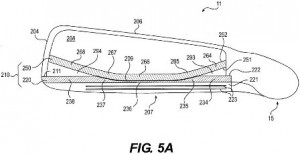

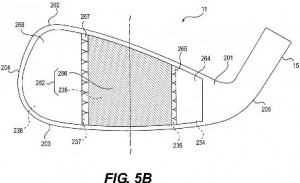

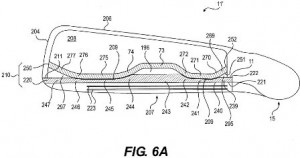

A golf club head having a reinforced striking face that includes a thin striking plate with a reinforcement plate disposed behind the striking plate. The striking face may have lubricant between the striking plate and reinforcement plate, separation volumes between the striking plate and reinforcing plate, or a combination thereof. The thicknesses of the striking and reinforcing plates may vary within the plates themselves and may have regions intended to mate with each other to create reinforced regions.

The application goes on to explain:

[0027] The reinforcing plate 150/250 may be an internal wall positioned within the hollow space 108/208 of the club head 10/11 for structurally reinforcing the striking plate 120/220. An outward facing surface 151/251 of the reinforcing plate 150/250 is in surface-to-surface contact with an inward facing surface 122/222 of the striking plate 120/220.

[0028] In particular, one or both of the striking plate 120/220 and the reinforcing plate 150/250 includes a layer of lubrication 109/209. In one aspect, the lubrication 109/209 is a layer of the striking plate 120/220, at the inward facing surface 122/22. In another aspect, the lubrication 109/209 is a layer of the reinforcing plate 150/250, at the outward facing surface 151/251. In a further aspect, there are two layers of lubrication 109/209 with one layer being a layer of the striking plate 120/220, at the inward facing surface 121/221 and the other layer being a layer of the reinforcing plate 150/250, at the outward facing surface 151/251. The lubrication 109/209 may also be formed as an entirely separate layer by coating the lubrication over the respective surface. Alternatively, the lubrication 109/209 may be formed as a surface treatment given to a surface for the respective plate to which it is applied. A thickness of lubrication 109/209 may be from about 1 micron to about 0.1 micron, with a thickness of a dual-layer lubrication 109/209 being from about 1 micron to about 0.2 micron. In one embodiment, the lubrication layer is about 0.75 micron to about 0.25 micron. In another embodiment, the lubrication layer is about 0.6 micron to about 0.3 micron. Non-limiting examples of lubrication materials may include oil, grease, silicone, wax, surface treatments (impregnated and non-impregnated), and combinations thereof.

[0029] Without being bound by any particular theory, the presence of the lubrication 109/209 facilitates the energy transfer from the striking plate 120/220 in concert with the reinforcement from the reinforcing plate 150/250, while minimizing shear stresses between the two plates. In particular, upon striking a golf ball, the thin-wall striking plate 120/220 will undergo a mechanical deformation resulting in both a rearward deflection and an arcuate expansion of the plate. If placed in direct surface-to-surface contact, the deflection and an arcuate expansion of the striking plate 120/220 would generate significant shear stresses on the outward facing surface 151/251 of the reinforcing plate 150/250.

[0030] However, due to the inclusion of the lubrication 109/209, the striking plate 120/220 is capable of deflecting and deforming separately from the reinforcing plate 150/250; and shear stresses between the plates 120/220 and 150/250 are substantially reduced. At the same time, because the lubrication 109/209 is only a thin layer, or even a mere surface treatment, between the plates 120/220 and 150/250, an energy from the deformation of the striking plate 120/220 is transmitted through the lubrication 109/209 and to the reinforcing plate 150/250 nearly instantly. Upon receiving the transmitted deformation force, the reinforcing plate 150/250 is momentarily deformed and generates a counterforce that is transmitted back through the lubrication 109/209 to the striking plate 120/220, thereby reinforcing the striking plate 120/220 against excessive deformation. In this manner, the surface-to-surface contact of the plates 120/220 and 150/250 permits the striking plate 120/220 to deform in a manner that increases energy transfer to a struck ball and permits the reinforcing plate 150/250 to generate a near instantaneous counterforce for reinforcing the striking plate 120/220. At the same time, the shear stresses that would otherwise result from a direct surface-to-surface contact between the plates 120/220 and 150/250 are minimized.

So, did anyone guess Acushnet (aka Titleist)? I doubt it.

What do you think, any chance this “technology” makes it into a commercial product?

PS – follow me on Twitter (@GolfPatents) and sign-up HERE to receive posts via email.

PPS – If you like what we are doing, please considering helping us out and make your online gear purchases through our Amazon affiliate link. Every little purchase helps us keep the site up and running! Thanks.