How is the Spew of Your Golf Ball Seam? Don’t Worry I Will Explain…

What is golf ball seam spew? Well, a recently issued Srixon (aka SRI Sports) patent provides a nice background explanation… As you may know, a golf ball is usually formed by upper and lower molds having hemispherical cavities. A molding method such as an injection molding method, a compression molding method or the like is employed.

Regardless of the type of molding, the molding material slightly leaks out of a parting line of the upper and lower molds. Accordingly, a ring-shaped spew is generated along the seam, which must be removed (typically by a cutting tool, grindstone, sandpaper, etc.). Often the resin of the seam is unexpectedly removed when the seam abuts on a grinding tool.

Obviously, such unexpected material removal is not ideal… after all, who wants to be able to see the seam, let alone be subjected to less than ideal ball flight characteristics?

Therein lies the goal of the Srixon invention… producing a golf ball having a higher uniformity by processing the seam of the golf ball more smoothly.

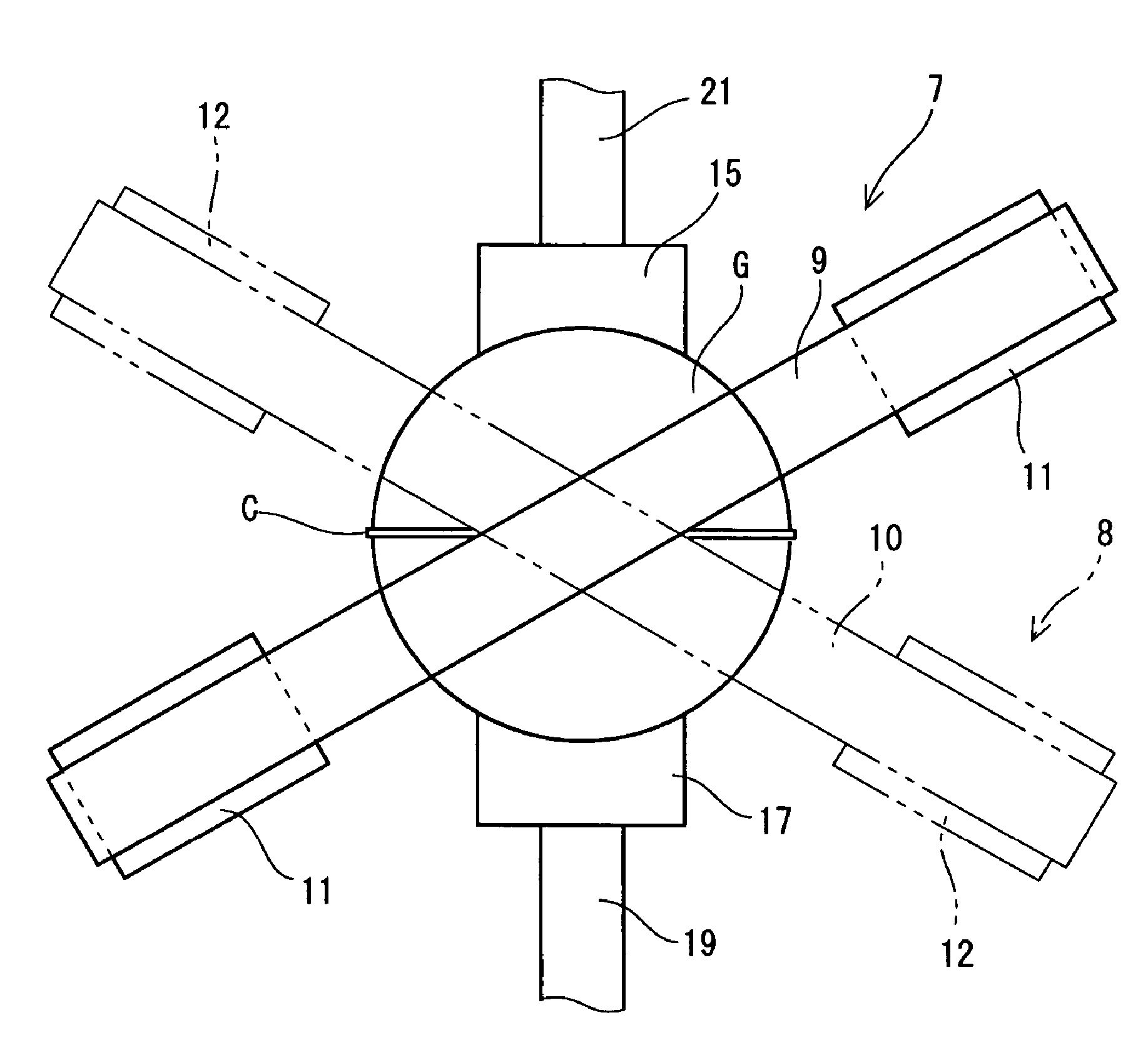

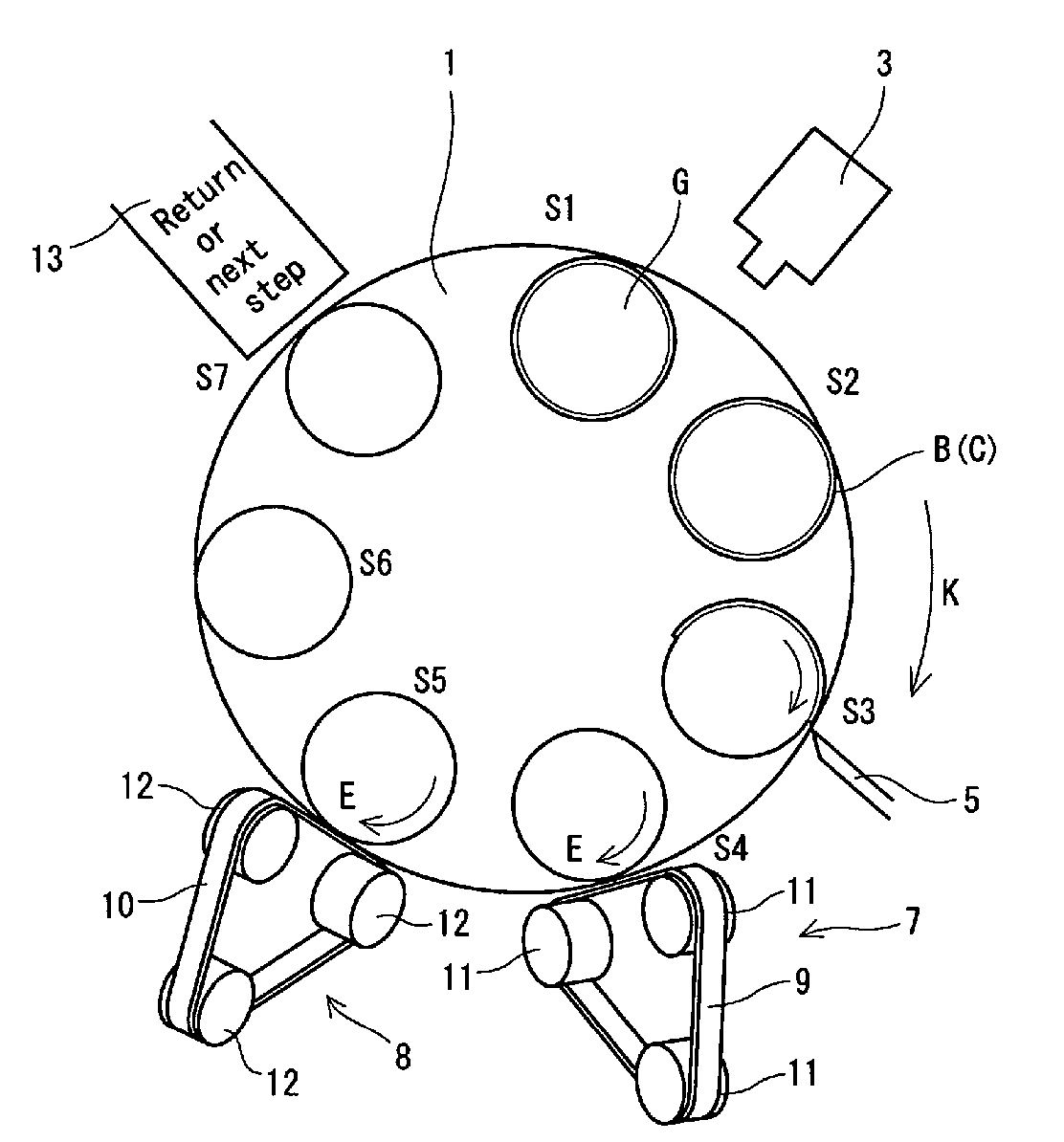

The invention is directed to a seam processing step of cutting or grinding the spew of the seam by means of a rotary processing tool having a processing direction inclined to the seam while rotating the golf ball in a circumferential direction of the seam. Sounds easy enough. The result should be a seam portion that is as small as possible with a smooth removal mark.

The patent is USPN 7273574 titled “Golf Ball Manufacturing Method.” Srixon produces some great golf balls, so check out this patent.

Congratulations Srixon.

Dave Dawsey – Dedicated to Golf Ball Inventions