Every Superintendent’s Worst Nightmare, Metal Golf Tees

I don’t know what to think about this recently published patent application. It there really a need for metal golf tees?

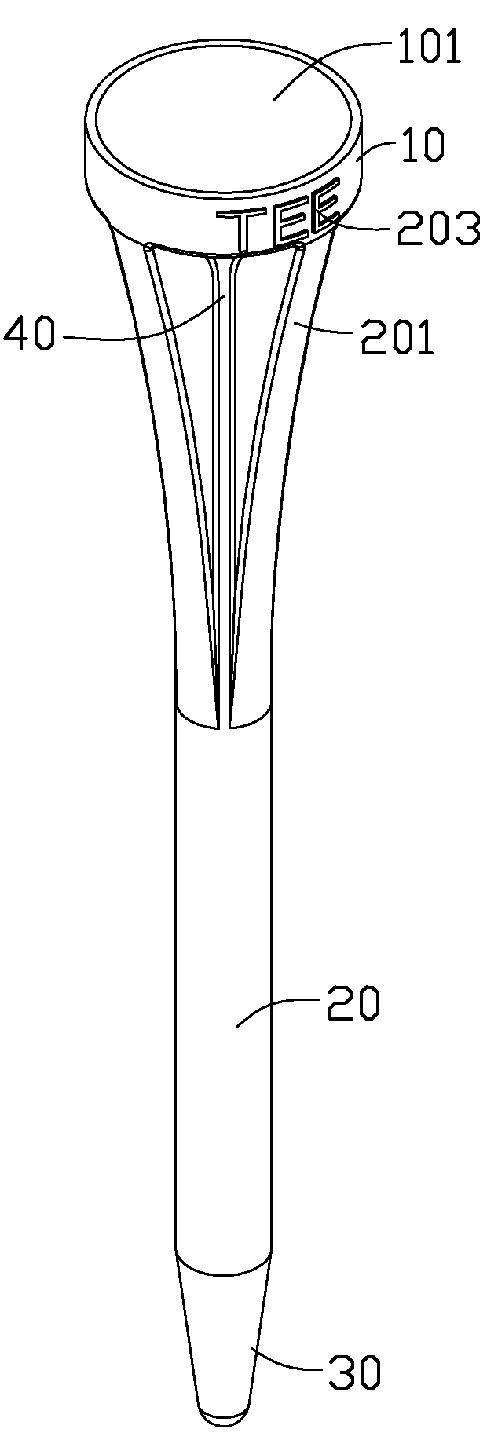

The patent application published today as US Pub. No. 20090170638 titled “Golf Tee and Method for Making Same” and describes the invention as:

An exemplary golf tee (100) includes a substrate (100a) and a coating film (100b). The substrate is made of metal or metal alloy. The coating film is formed on an outside surface of the substrate. The present invention also provides a method for making the exemplary golf tee. The method includes providing a roughcast made of metallic or metallic alloy material; forming the substrate by a method of die-casting with the roughcast; and forming the coating film on an outside surface of the substrate by a method of surface treating.

The application goes on to explain the need as (try to ignore the awkward translation language):

[0004] Golf tees are commonly used at driving ranges and golf courses to position the golf ball above the ground. Recently, more and more golf tees are required with golf game being more and more popular.

[0005] Typical golf tees are generally wooden tees, plastic tees, or bamboo tees. Such golf tees have many shortcomings. For example, for wooden tees and bamboo tees, the following shortcomings exist. (1) Wooden tees and bamboo tees are weak in strength and toughness. Such golf tees, particularly connecting portions of heads and bodies of golf tees, are easily worn out by hitting with golf club. Thus, wooden tees and bamboo tees have short service lives. In addition, wooden tees and bamboo tees can be only inserted into the ground with a small length because of the low strength thereof. (2) Wooden tees and bamboo tees are affected by moisture and expand on rainy days or when the ground is damp. As such, the strength of the golf tees reduces. In addition, damped, wooden, or bamboo golf tees with rough surfaces are difficult to clean. (3) Wooden tees and bamboo tees are manufactured one by one, thus a manufacturing efficiency is very low. Furthermore, each golf tee is generally different from others. That is, it is quite difficult to make golf tees with the same size and shape. (4) It is difficult to form patterns such as letterings, inscriptions, pictorial images on wooden tees and bamboo tees. Even if figures are formed on such golf tees, the figures are easily worn off. (5) Wooden tees and bamboo tees have low hardness. Thus, the golf tees usually have rough surfaces after being abraded because of the low hardness. The golf tees have awful property in aesthetics.

[0006] For plastic tees, the following shortcomings exist. (1) Plastic tees have low hardness. Thus, depressions and projections are formed on the golf tees when hit by golf club. The golf tees have awful property in aesthetics. (2) Plastic tees are easily deformed in use. (3) Plastic tees are difficult to be decomposed. Disused plastic tees would become pollutions.

Are you sold? Not me!

Dave Dawsey – Keeping an Eye on Golf Tee Inventions

PS – check out other golf tee related posts here