Driver of the Future? Probably Not

I have heard that some golfers cannot hit the ball on the club head sweet spot. Hard to believe, I know. Well if you are one of those unfortunate golfers then the club disclosed in USPN 7070514 titled “Golf Club Head Having Internal Impact Assembly” may be just what you need. The patent describes the invention as:

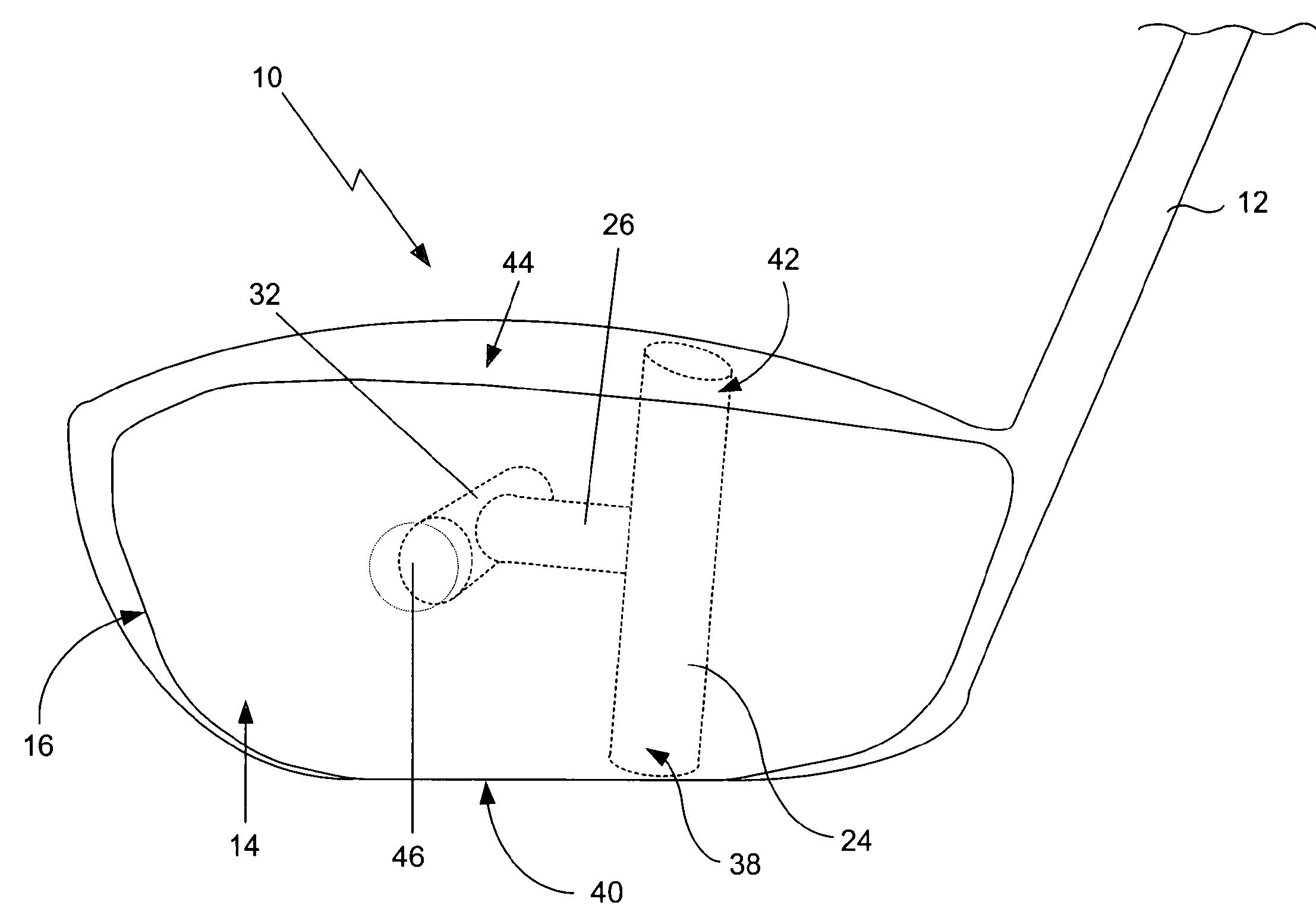

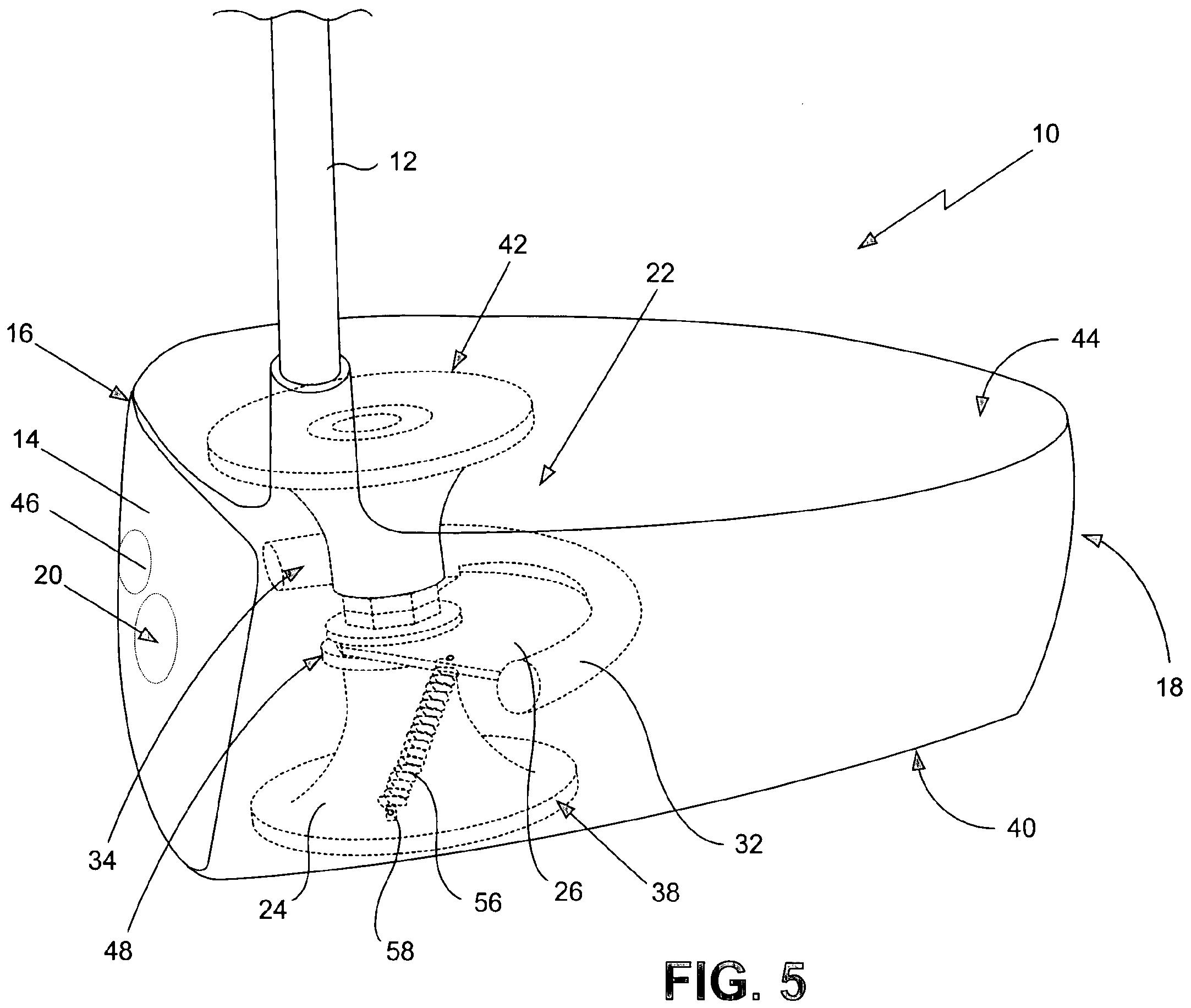

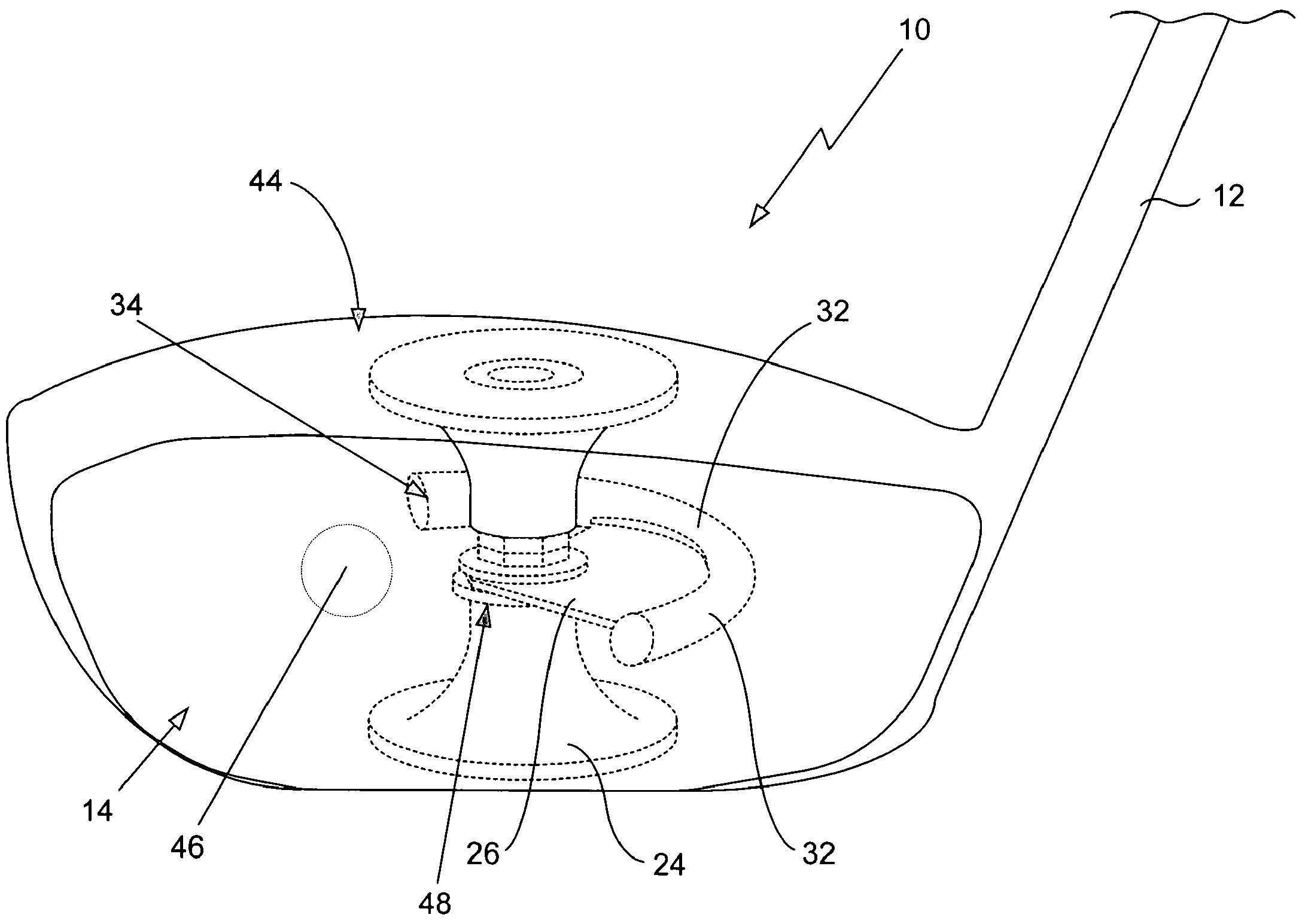

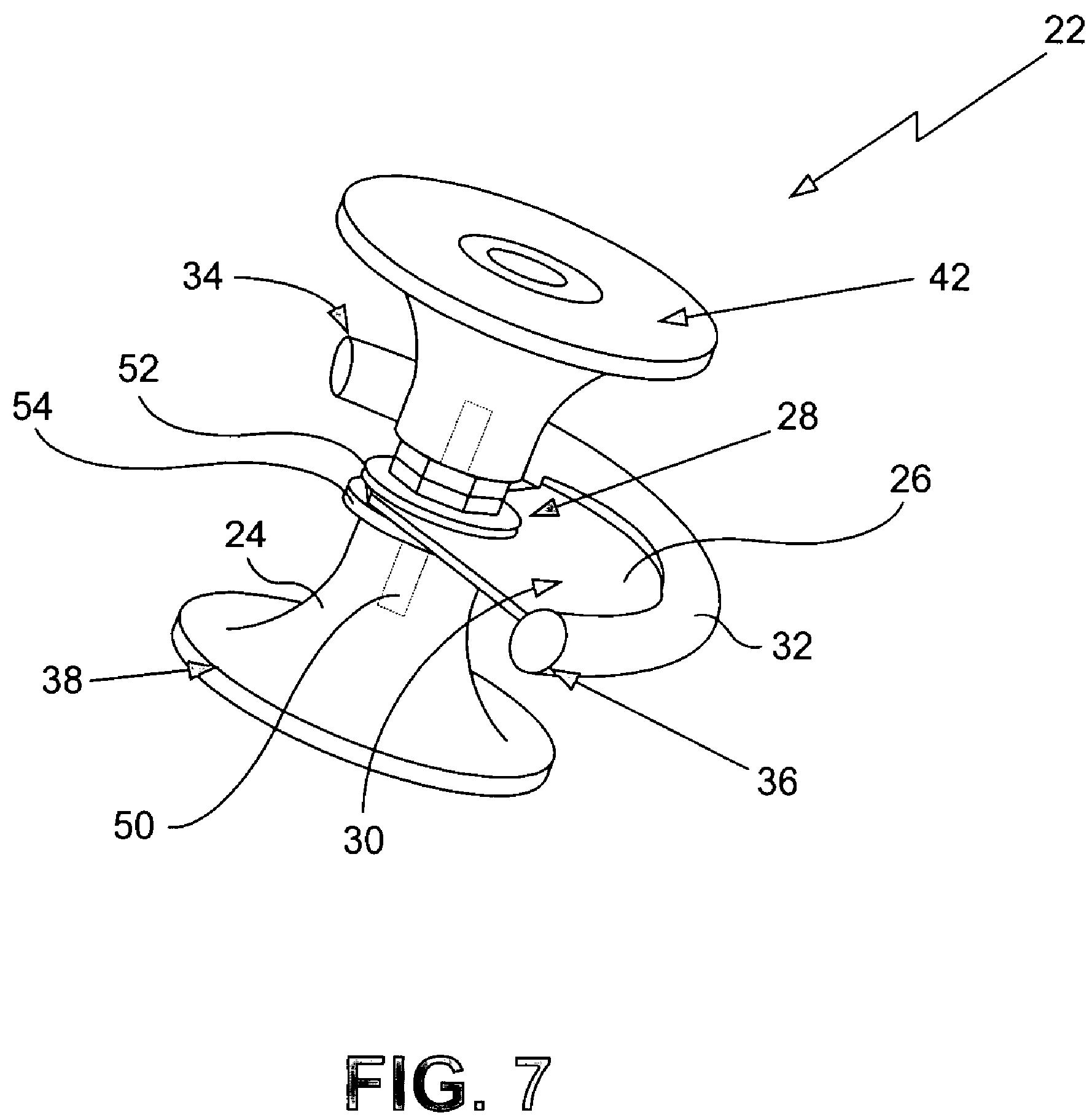

An improved golf club head having an internal impact assembly configured to improve the direction and distance of travel of a golf ball. The impact assembly is configured to impact the inside wall of the club face at an impact spot immediately after the golf ball is hit to provide a kick to the golf ball so as to direct it along the desired direction of travel. The impact assembly is in a club head cavity and comprises a support member attached to the cavity, a spaced apart hammer member and a connecting member interconnecting the support member and hammer member. In a preferred embodiment, the connecting member is fixed to the support member and configured, such as being made out of graphite or the like, to flex the hammer member into the impact spot. In an alternative embodiment the connecting member is pivotally connected to the support member.

What! Check out these figures:

The patent goes on to explain:

What is needed, therefore, is a golf club head that improves the flight direction and distance of a golf ball regardless of whether the golfer strikes the golf ball exactly at the desired sweet spot. An improved golf club head will provide a mechanism for effectively correcting the golfer’s strike against the golf ball such that the golf ball will travel in a generally desired straight direction. The desired improved golf club head will correct the common problems of slicing and/or hooking of the golf ball and will provide greater traveling distance for the golf ball along the desired direction of travel.

That is to say, the present invention discloses a golf club head that substantially improves the direction of travel and distance of a golf ball that is hit by the club head when the golfer fails to hit the ball exactly at the club head’s sweet spot. The preferred embodiments of the improved golf club head of the present invention utilizes an internal impact assembly to effectively correct a golfer’s swing by countering the effect of not hitting the golf ball at the club head’s sweet spot, thereby improving both the direction and amount of travel of the hit golf ball. The internal impact assembly of the preferred embodiments automatically effect the contact by the club face against the golf ball so as to counter not hitting the ball exactly at the club head’s sweet spot by impacting the back of the club face at a spot offset from the sweet spot. As such, the improved golf club head of the present invention will allow the golfer to better hit the golf ball so as to cause it to travel in the direction desired by the golfer, as opposed to slicing and/or hooking the golf ball.

In one general aspect of the present invention, the improved golf club head comprises an impact assembly disposed inside the club head cavity that is configured to deliver an impact to the wall of the cavity behind the club face at an impact spot so as to provide a slight kick or blow to the golf ball immediately after it is hit by the golf club head to better direct the hit golf ball along the desired direction of travel. In a preferred embodiment, the impact assembly comprises a support member that is attached to one or more of the walls of the cavity, a spaced apart hammer member configured to impact the impact spot and a connecting member interconnecting the support member and the hammer member. Preferably, the connecting member is fixed to the support member so the impact assembly does not constitute a moving component in violation of the relevant golf rules and regulations. In this embodiment, the connecting member is configured to flex and then direct the hammer member into the impact spot in response to the change in momentum resulting from the impact of the club face against the golf ball. Like the club shaft, which although it flexes during the golfer’s swing is considered a non-moving part, the flexing of the impact assembly is also a non-moving part. The connecting member can be shaped and configured to achieve the desired flexing. In one embodiment, the connecting member is an elongated shaft. The connecting member can be made out of a material that provides the desired, relatively small amount, of flexing, such as graphite or similar materials. As the club head is swung in the downward direction, the connecting member will allow the hammer member to flex toward the back of the club head. When the club face hits the golf ball, the flexing nature of the connecting member will allow the inertia force of the hammer to be driven against the inside wall of the club face at the impact spot to deliver the desired kick to the golf ball. In an alternative embodiment, the connecting member is pivotally attached to the support member to pivot the hammer member into the back wall of the club face. Various pivoting mechanisms can be utilized to connect the connecting member to the support member. In one embodiment, the connecting member pivots around a pivot shaft component of the support member and the hammer member has a curvilinear shape generally matching the direction of travel of the hammer member during its pivoting travel. In another alternative embodiment, the impact assembly comprises a tube or channel disposed in the golf club head and a ball that rolls in the tube or channel to contact the back wall of the club face. A spring can be positioned at the back end of the tube or channel to improve the action of the ball during the upswing portion of the golf stroke.

That is to say, the present invention discloses a golf club head that substantially improves the direction of travel and distance of a golf ball that is hit by the club head when the golfer fails to hit the ball exactly at the club head’s sweet spot. The preferred embodiments of the improved golf club head of the present invention utilizes an internal impact assembly to effectively correct a golfer’s swing by countering the effect of not hitting the golf ball at the club head’s sweet spot, thereby improving both the direction and amount of travel of the hit golf ball. The internal impact assembly of the preferred embodiments automatically effect the contact by the club face against the golf ball so as to counter not hitting the ball exactly at the club head’s sweet spot by impacting the back of the club face at a spot offset from the sweet spot. As such, the improved golf club head of the present invention will allow the golfer to better hit the golf ball so as to cause it to travel in the direction desired by the golfer, as opposed to slicing and/or hooking the golf ball.

In one general aspect of the present invention, the improved golf club head comprises an impact assembly disposed inside the club head cavity that is configured to deliver an impact to the wall of the cavity behind the club face at an impact spot so as to provide a slight kick or blow to the golf ball immediately after it is hit by the golf club head to better direct the hit golf ball along the desired direction of travel. In a preferred embodiment, the impact assembly comprises a support member that is attached to one or more of the walls of the cavity, a spaced apart hammer member configured to impact the impact spot and a connecting member interconnecting the support member and the hammer member. Preferably, the connecting member is fixed to the support member so the impact assembly does not constitute a moving component in violation of the relevant golf rules and regulations. In this embodiment, the connecting member is configured to flex and then direct the hammer member into the impact spot in response to the change in momentum resulting from the impact of the club face against the golf ball. Like the club shaft, which although it flexes during the golfer’s swing is considered a non-moving part, the flexing of the impact assembly is also a non-moving part. The connecting member can be shaped and configured to achieve the desired flexing. In one embodiment, the connecting member is an elongated shaft. The connecting member can be made out of a material that provides the desired, relatively small amount, of flexing, such as graphite or similar materials. As the club head is swung in the downward direction, the connecting member will allow the hammer member to flex toward the back of the club head. When the club face hits the golf ball, the flexing nature of the connecting member will allow the inertia force of the hammer to be driven against the inside wall of the club face at the impact spot to deliver the desired kick to the golf ball. In an alternative embodiment, the connecting member is pivotally attached to the support member to pivot the hammer member into the back wall of the club face. Various pivoting mechanisms can be utilized to connect the connecting member to the support member. In one embodiment, the connecting member pivots around a pivot shaft component of the support member and the hammer member has a curvilinear shape generally matching the direction of travel of the hammer member during its pivoting travel. In another alternative embodiment, the impact assembly comprises a tube or channel disposed in the golf club head and a ball that rolls in the tube or channel to contact the back wall of the club face. A spring can be positioned at the back end of the tube or channel to improve the action of the ball during the upswing portion of the golf stroke.

Sure, that sounds like it would work flawlessly! Now if only I can get my hands on one of them, you will see me on the Tour with Tiger as my caddie.

Dave Dawsey – Keeping an Eye on Golf Inventions

PS – click here to check out other driver and wood design posts