Do You Really Understand the Technology in Your Golf Shaft? Harrison Sports Granted Interesting Golf Shaft Patent

Golf shaft technology is fascinating, partly because it is so misunderstood. Well, this week Harrison Sports, Inc. was granted a shaft patent that may provide you with an inside look at some of their unique technology.

The patent is USPN 7497786 titled “Golf Club Shaft Having Multiple Metal Fiber Layers,” presumably directed to their reinforced graphite shafts. The patent explains:

Many substitutes have been introduced for the hard wood shafts originally used in golf club drivers and irons. Early substitute materials included stainless steel and aluminum. More recently, carbon fiber reinforced resin shafts have become popular. Such shafts are typically hollow and consist of a shaft wall formed around a tapered mandrel. The use of fiber reinforced resin has allowed golf club manufacturers to produce shafts having varying degrees of strength, flexibility and torsional stiffness. As such, manufacturers are able to produce shafts which suit the needs of a wide variety of golfers.

Nevertheless, manufactures are faced with a variety of design issues that have proven difficult to overcome using conventional fiber reinforced resin technologies. For example, some golfers prefer that the center of gravity of the shaft be shifted towards the tip of the shaft in order to increase the striking force when the club head impacts the golf ball. This can be difficult to accomplish with conventional technologies because composite materials are generally light. It is also preferable in some instances to increase the kick of the shaft. One conventional method of increasing the kick of a shaft is to use a large number of graphite fibers that have a very high modulous of elasticity. This method is, however, very expensive. Another method is to alter the shape of the shaft, as is disclosed in commonly assigned U.S. Pat. No. 5,957,783. Another design issue is the location of the shaft flex point and, more specifically, the inability of shaft designers to precisely predict the location of the flex point when designing a shaft without using excessive amounts of composite material, which can lead to weight and thickness issues.

The patent describes the invention as:

The general object of the present invention is to provide a golf club shaft that eliminates, for practical purposes, the aforementioned problems. In particular, one object of the present invention is to provide a golf club shaft with more mass in and around the tip section than conventional shafts. Another object of the present invention is to provide a golf club shaft with increased kick that does not require a large number of carbon fibers with a high modulus of elasticity. Still another object of the present invention is to provide a golf club shaft which facilitates precise location of the flex point.

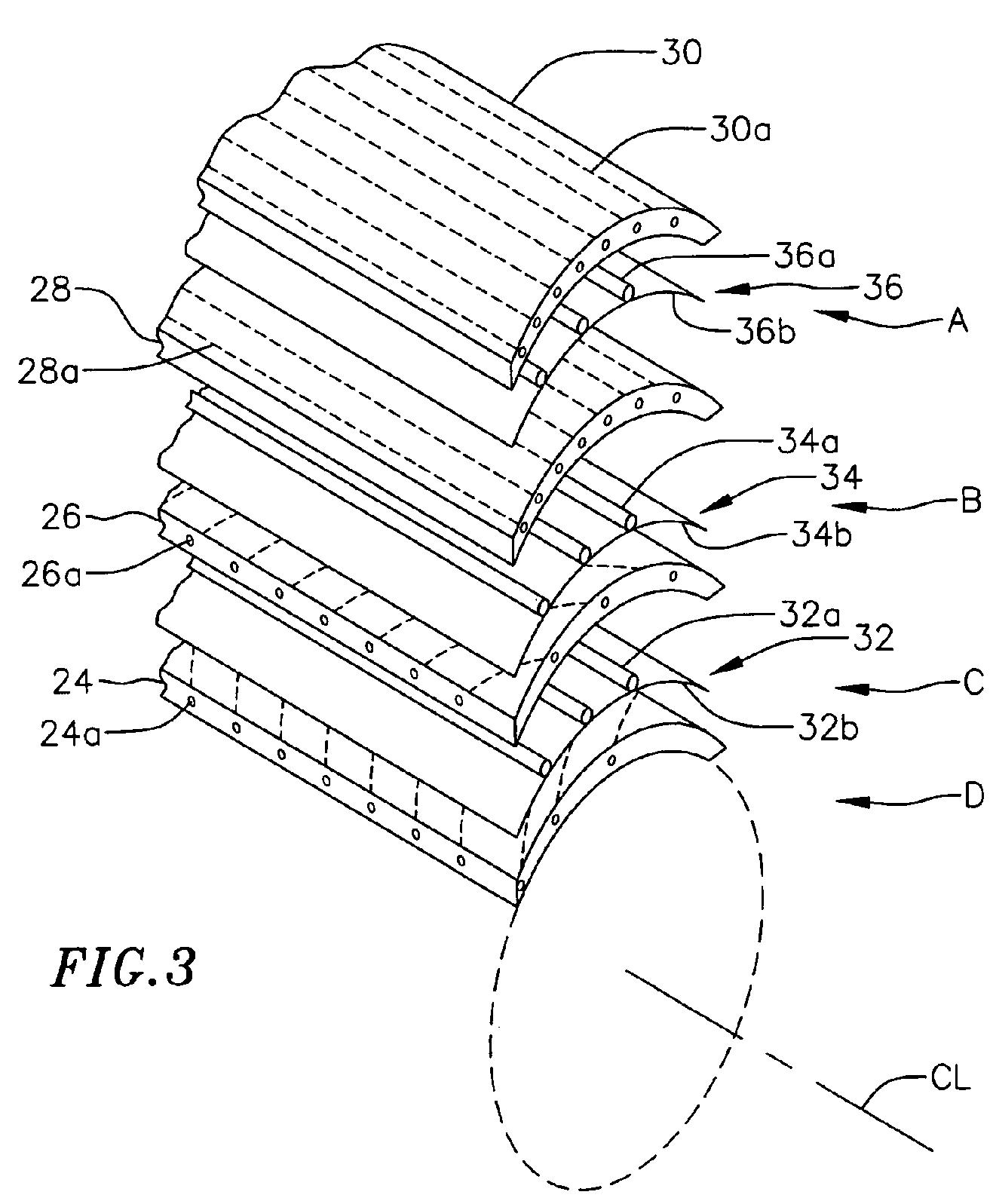

In order to accomplish these and other objectives, a golf club shaft in accordance with the present invention includes a plurality of fiber reinforced resin layers and respective pluralities of at least first and second metal fibers that are different from one another in at least one way. Use of the metal fibers allows golf club shafts to manufactured with certain properties that correspond to the fibers themselves. Use of the metal fibers also allows these properties to be achieved in a manner that is easier, more accurate, and more cost effective than can be achieved with conventional fiber reinforced resin manufacturing techniques.

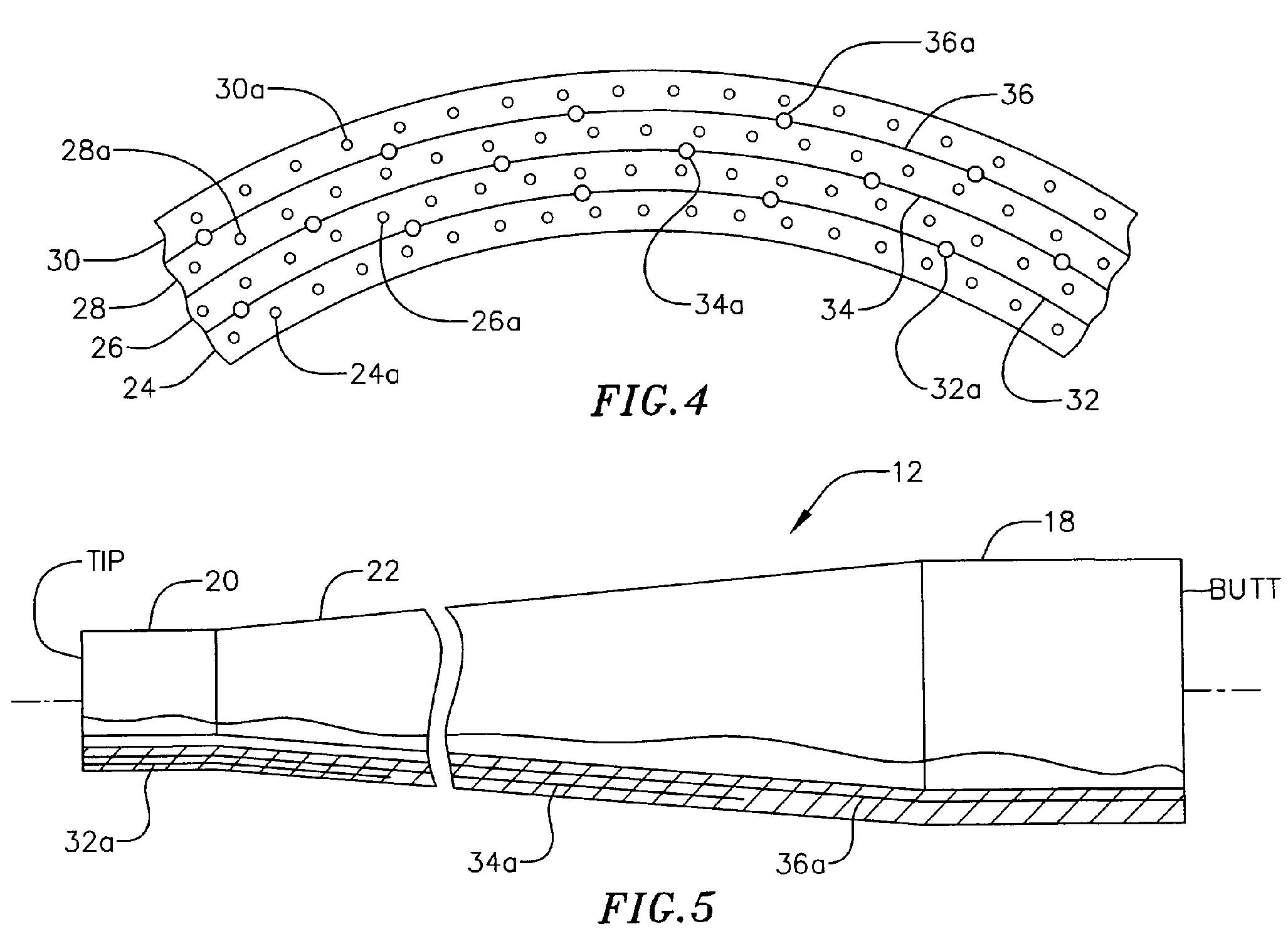

For example, one embodiment of the present invention includes three different groups of metal fibers, i.e. a plurality of relatively heavy metal fibers, a plurality of relatively stiff metal fibers and a plurality of relatively resilient metal fibers. The ends of the metal fibers are aligned with the tip. The relatively heavy metal fibers preferably extend about 5 inches to about 8 inches from the tip and are primarily used to increase the mass of the shaft in and around the tip section. The relatively stiff metal fibers, which are primarily used to define the flex point of the shaft, preferably extend about 10 inches to about 16 inches from the tip. The relatively resilient metal fibers extend at least about 20 inches from the tip and are primarily used to increase the kick of the shaft.

Check out these drawings:

Good stuff!

David Dawsey – Monitoring Golf Shaft Patents

PS – check out other golf shaft patent posts here