Do You Know What RIP Stands For?

Did you know that the Aldila RIP technology is short for “reverse interlaminar placement?” Their RIP patent application recently published and provides all the details. The application published as US Pub. No. 20110294593 and describes the invention as:

A golf club shaft is formed having a flexural rigidity layer at last one third the length of which is encased in an outer layer. The shaft is formed by applying sheets of composite material to a mandrel. Sheets forming the flexural rigidity layer include unidirectional fibers oriented substantially in parallel with the longitudinal axis of the shaft. The outer layer may include composite material sheets each having unidirectional fibers oriented at an angle with respect to the shaft’s longitudinal axis. An innermost layer of the shaft may be formed of composite material sheets having fibers oriented at an angle with respect to the shaft’s longitudinal axis.

The application goes on to explain:

BACKGROUND OF THE INVENTION

[0003] Composite golf club shafts typically have hollow tubular bodies that taper longitudinally from larger, so-called “butt” or “grip” ends toward smaller, so-called “tip” ends upon which golf club heads are mounted in the completed golf clubs. Such shafts typically are generally circular in transverse cross-sectional shape, both at the outside and inside surfaces of the shaft, having walls that are of selected thicknesses and compositions to provide the strength, flexibility and weight desired for a particular golf club.

[0004] The design and manufacture of composite golf club shafts are highly developed arts, providing a wide variety of different shafts with characteristics that are intended to suit the abilities and personal preferences of a wide variety of golfers. Typically, composite shafts are designed to be concentric about their longitudinal axis while varying substantially in outside diameter from the larger grip end to the smaller tip end. The concentricity of the inside and outside surfaces is designed to be very precise, to produce the desired wall thickness and flexing characteristics, and remains stable when at rest, that is, when not loaded and stressed by outside forces.

[0005] During the swing, however, the forces acting on the shaft as the club is swung through the golf stroke are great enough to deform the shaft, longitudinally in flexing of the length of the shaft and torsionally in twisting of the shaft, and also transversely, causing the cross-sectional shape of the shaft to deform and become oval or elongated. Thus deformation is resisted by the wall strength of the shaft, referred to as “hoop strength”, but occurs in different degrees and directions, first in the so-called “swing plane (or planes)” of the golfer’s swing and secondarily in the so-called “droop plane” that is generally perpendicular to the swing plane. The amounts of these deformations are functions of the forces applied throughout the swing and ball impact, and the physical properties of the shaft resisting these forces.

[0006] In the industry, various approaches are available to provide the desired properties in the shaft for improved performance, including increasing the wall thickness and the amounts of different composite materials in the wall, and varying the angles of the fibers in the composite materials relative to the longitudinal axis of the shaft.

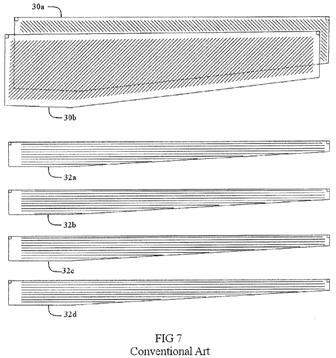

[0007] However, conventional composite golf shafts typically include bias plies with fibers substantially oriented plus and minus 45 degrees to the shaft axis to influence torsional (twisting) flexibility, and longitudinal plies with fibers parallel to the shaft axis to influence longitudinal (bending) flexibility. The bias plies 30a, 30b illustrated in FIG. 7 are applied closest to the center core of the golf shaft and the longitudinal fiber plies 32a to 32d are applied concentrically about the inner bias plies 30a, 30b last, and furthest from the core of the shaft. Although the figure shows two bias plies and four longitudinal plies, the number may vary. After curing, an amount of material is removed from the outermost longitudinal ply 32d of the golf shaft (e.g., by sanding) to obtain a desired shaft stiffness. A significant portion of the longitudinal fibers are thus sanded away. The conventional composite golf shaft loses approximately 5.75% of its stiffness during this material removal process.

SUMMARY OF THE DISCLOSURE

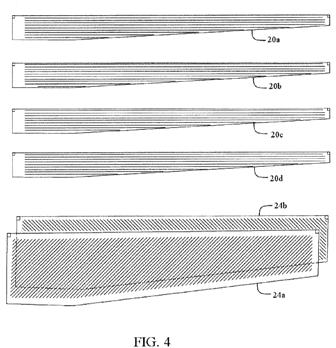

[0008] Consistent with one or more embodiments described in detail herein, a golf club shaft includes an elongated, generally tapered shaft having a generally circular transverse cross-sectional shape. The circular wall of the shaft has at least one flexural rigidity layer and at least one outer layer. The flexural rigidity layer(s) are disposed around the entire length of the shaft, and reinforcement fibers of the flexural rigidity layer(s) are substantially oriented in the longitudinal direction of the shaft. The outer layer(s) have no longitudinally-oriented fibers and are disposed concentrically about the outermost flexural rigidity, and extend at least one third the length of the shaft from a tip end of the shaft.

[0009] Consistent with one or more method embodiments described in detail herein, a golf club shaft is produced by steps including providing an elongated mandrel, applying flexural rigidity layer(s) and applying outer layers. The mandrel has an outside surface shaped to form the inside surface of the shaft. The flexural rigidity layer, of composite material, is applied about the entire length of the mandrel and includes reinforcing fibers which are oriented substantially parallel to the longitudinal axis of the mandrel to form a tubular body for the shaft. The outer layer(s) are applied concentrically about the flexural rigidity layer(s), and at least one outer layer has no longitudinally-oriented fibers. The at least one outer layer is disposed over at least one third the longitudinal length of the shaft.

You learn something new everyday.

Dave Dawsey – Monitoring Golf Shaft Patent Applications

PS – click HERE to read about more golf shaft inventions