Are Your Shafts Retaining Austenite? Poor Things

Golf shaft technology is as interesting as any golf technology. In fact, I suspect the popularity of golf shaft technology will grow each week as major tournament broadcasts increase the number of slow motion SwingVision videos showing the gyrations of a shaft as a Tour player hacks their ball out of deep rough.

This week the Nippon Shaft Company was granted an interesting golf shaft patent. The patent is USPN 7578750 titled “Golf Shaft, Golf Club, and Production Method for Golf Shaft” and explains:

The weight of a metal golf shaft is desirably reduced in order to increase the flight distance of a golf ball. This desire has been met by reduction in wall thickness of a golf shaft having a hollow tubular shape. However, since it is necessary to satisfy the SG standard for ensuring the safety golf shafts, strengthening of the material in golf shafts is necessary in order to reduce the wall thickness thereof.

For example, Japanese Unexamined Patent Application Publications Nos. 2005-34517 and 2005-13535 disclose techniques for strengthening a material of a metal golf shaft. In the technique disclosed in Japanese Unexamined Patent Application Publication No. 2005-34517, an alloy type steel product having a high strength and a high toughness is subjected to sub-zero treating, and a material of a metal golf shaft thereby has a martensite structure. Next, the material of the metal golf shaft is subjected to tempering, so that the toughness thereof is restored. As a result, the metal golf shaft can have strength and toughness. In the technique disclosed in Japanese Unexamined Patent Application Publication No. 2005-13535, amount of retained austenite included in an alloy type steel product having a high strength and a high toughness is adjusted, and a metal golf shaft having a light weight can be superior in strength, toughness, elasticity, and rebound force, and the like.In the conventional techniques, in order that a material of golf shaft is uniform in a thickness direction and in a longitudinal direction, material composition, metal structure, grain size, and hardness are adjusted so that the material of golf shaft is superior in balance of strength and toughness. In the conventional techniques, the material of the golf shaft had to be substantially uniform in a thickness direction and a longitudinal direction regardless of the magnitudes of stresses generated to the golf shaft. However, when a golf shaft is used under a bending stress, the stress is maximal at a surface of the golf shaft. In addition, a high stress is applied to a grip side of the golf shaft. Thus, when a material is adjusted so as to optimize a portion to which a high stress is applied, a portion to which a low stress is applied has an excessive quality. Since retained austenite has a soft structure, the strength and the proof stress are decreased, inferior effects may be obtained. When the amount of retained austenite is increased, the toughness is improved, but the strength is decreased. Due to this, it is difficult to simultaneously improve both the strength and the toughness.

SUMMARY OF THE INVENTION

Therefore, the present invention was made in consideration of the above problems. An object of the present invention is to provide a light weight golf shaft having a high strength and a high toughness by adjusting the amount of retained austenite and grain size in a thickness direction and in a longitudinal direction.

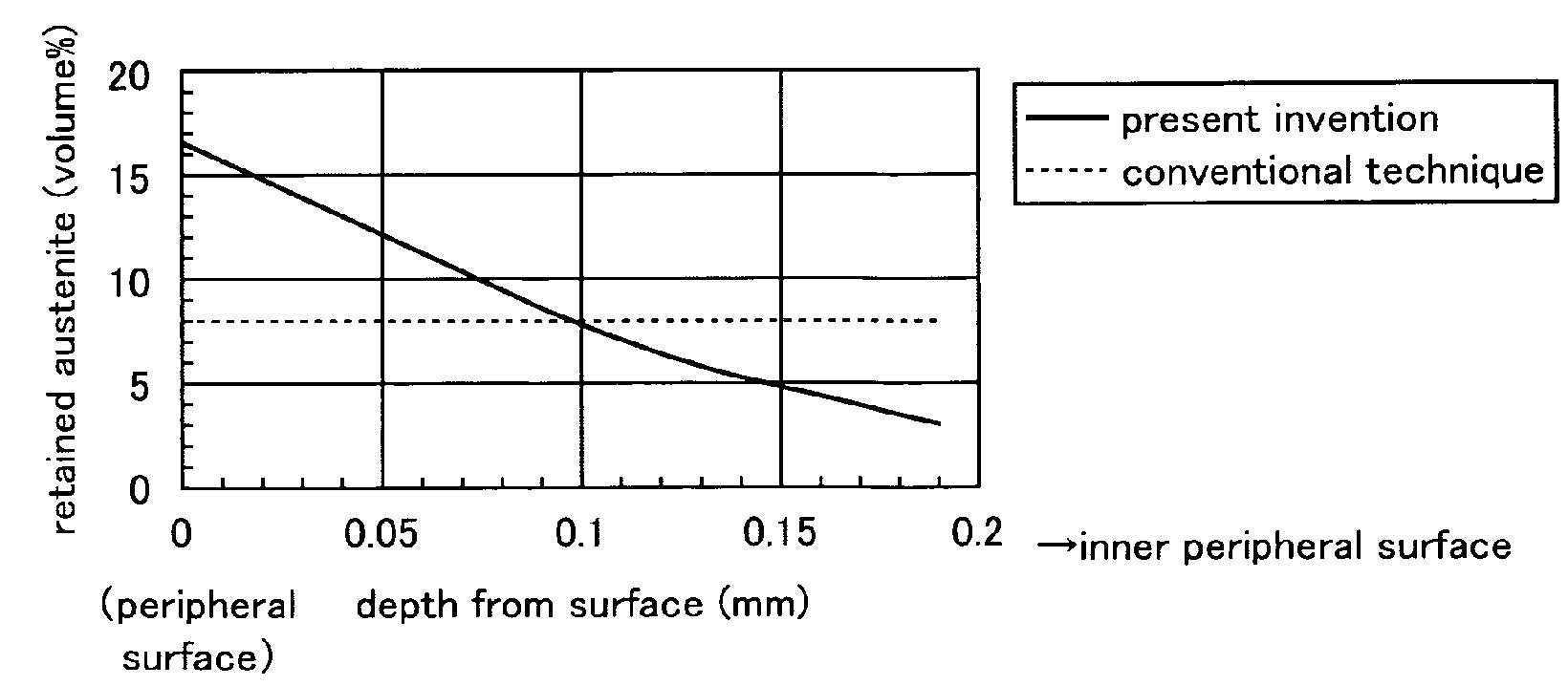

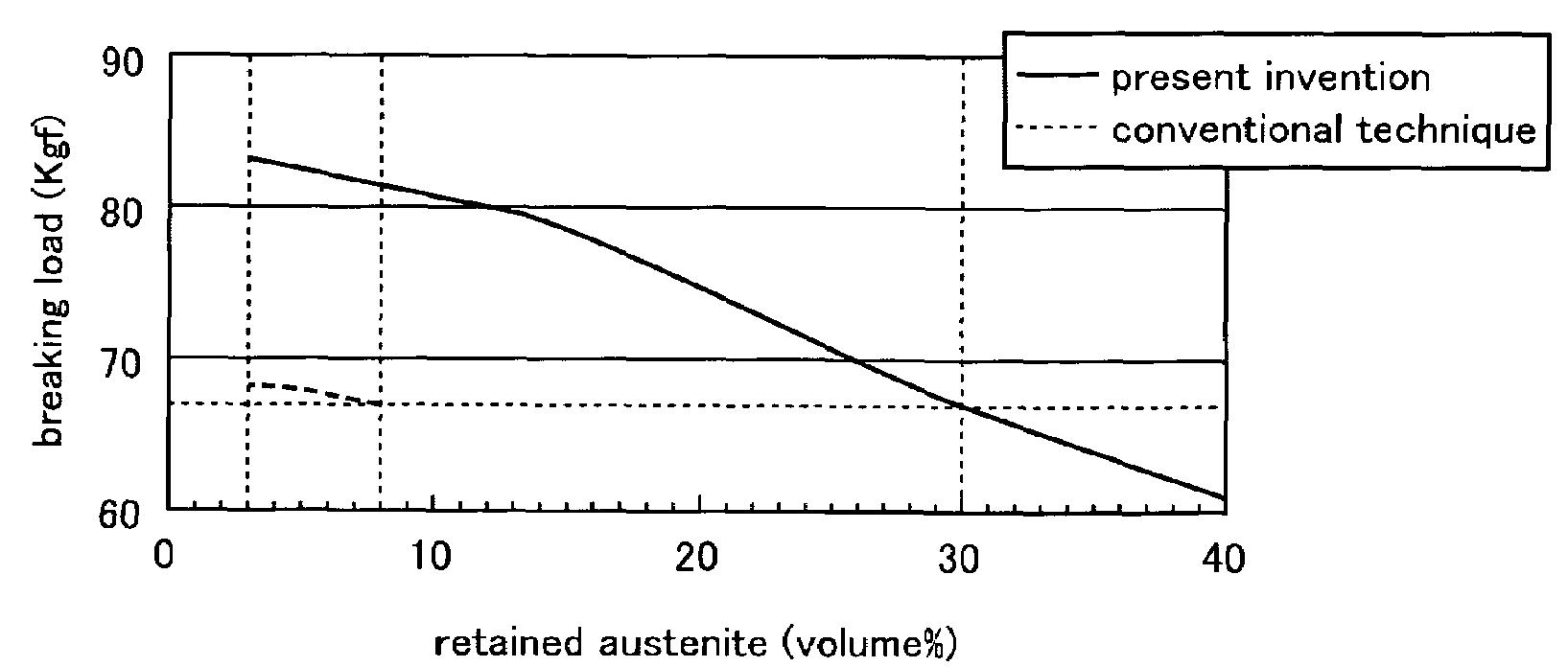

According to one aspect of the present invention, a golf shaft includes: a hollow tubular structure; and a gradient structure in which amount of retained austenite is increased from an approximate center in a thickness direction of the hollow tubular structure to a surface of the hollow tubular structure. In the golf shaft of the present invention, the amount of retained austenite is increased from the thickness center portion of the hollow tubular structure to the surface of the hollow tubular structure. Thus, deformation amount of the golf shaft is larger at the surface portion (that is, toughness of the golf shaft is higher at the surface portion), and strength of the golf shaft is higher by transformation-induced plasticity effect when a stress is applied to the golf shaft. At a portion inside from the surface (that is, a deep portion), the applied stress is small, and the transformation-induced plasticity effect may be small. Due to this, if the amount of the retained austenite is not small at the deep portion, the strength of the golf shaft may be deteriorated. However, in the golf shaft of the present invention, since the amount of the retained austenite is relatively small at the thickness center portion, the strength of the golf shaft can be improved.

When a stress is applied to a metal material including the retained austenite, a soft austenite structure is transformed into a hard martensite structure, and a transformation-induced plasticity effect, which causes a high toughness by dispersion and propagation of distortion, is generated. In the golf shaft of the present invention, the included amount of the retained austenite is increased toward the outside surface of the golf shaft. Thus, at the outside surface of the golf shaft at which the applied stress is larger when the bending force is applied to the golf shaft, the above transformation-induced plasticity is preferentially generated, and the deformation of the golf shaft occurs while the austenite structure is transformed into the martensite structure. That is, the golf shaft has a gradient structure such that the amount of retained austenite is increased from the inside portion of the hollow tubular structure to the outside surface of the hollow tubular structure, so that the generation ability of the transformation-induced plasticity is higher toward the outside surface at which the applied stress is larger in the bending, and the strength and the toughness of the golf shaft can be higher.

Since the transformation-induced plasticity may be small at the deep portion at which the applied stress is relatively small in the bending, it is necessary to improve the strength by reducing the amount of the retained austenite thereat. This action in the thickness direction of the shaft is interactively performed, so that the material can obtain both high strength and high deformability, that is, high toughness.

This advantage is good in straightening of a bent portion. That is, in the straightening, force is applied such that bent golf shaft is forcibly straightened, so that a stress applied to the golf shaft is maximal at the outside surface in the same manner described above. Thus, in the same manner described above, while the deformability (ability of the golf shaft which can be deformed without breakage thereof) in the straightening is obtained at a higher level, the strength can be improved, and breakage of golf shaft in the straightening can be prevented.

According to a preferred embodiment of the present invention, the golf shaft includes 5 to 30 volume % of the retained austenite at an outside surface of the hollow tubular structure and in the vicinity of the outside surface. The position range of the outside surface of the hollow tubular structure and the vicinity of the outside surface may be defined within a depth of 3 micrometers from the outside surface.

Got that? Time to brush up on your metallurgy! It seems that golf shaft patenting is picking up.

David Dawsey – M

onitoring Golf Shaft Patents

PS – check out other golf shaft patent posts here