Would You Game a Plastic Driver? Author of Several Golf Club R&D Books Receives Interesting Plastic Club Head Patent

You may recall a prior post that introduced you to golf inventor Dr. Frank D. Werner? He is the author of a handful of books (example 1, example 2) on golf club engineering, and was one of the early supporters of square drivers (see THIS prior post). Based upon his bio, it appears Frank is one smart guy.

Well, Frank was recently granted USPN 7597634 titled “Plastic Golf Club Head.” The patent explains:

Prior art wood-type club heads have been made of various sturdy plastics with small head size, commonly expressed as small volume heads. The small volume allowed bonded joints between head parts to be broad and to have low maximum stress. Thus, the severe stresses of head-ball impact did not overstress the broad bond joints. An important and undesirable consequence of the small size and material choice was that they had negligible spring effect.

.

.

.

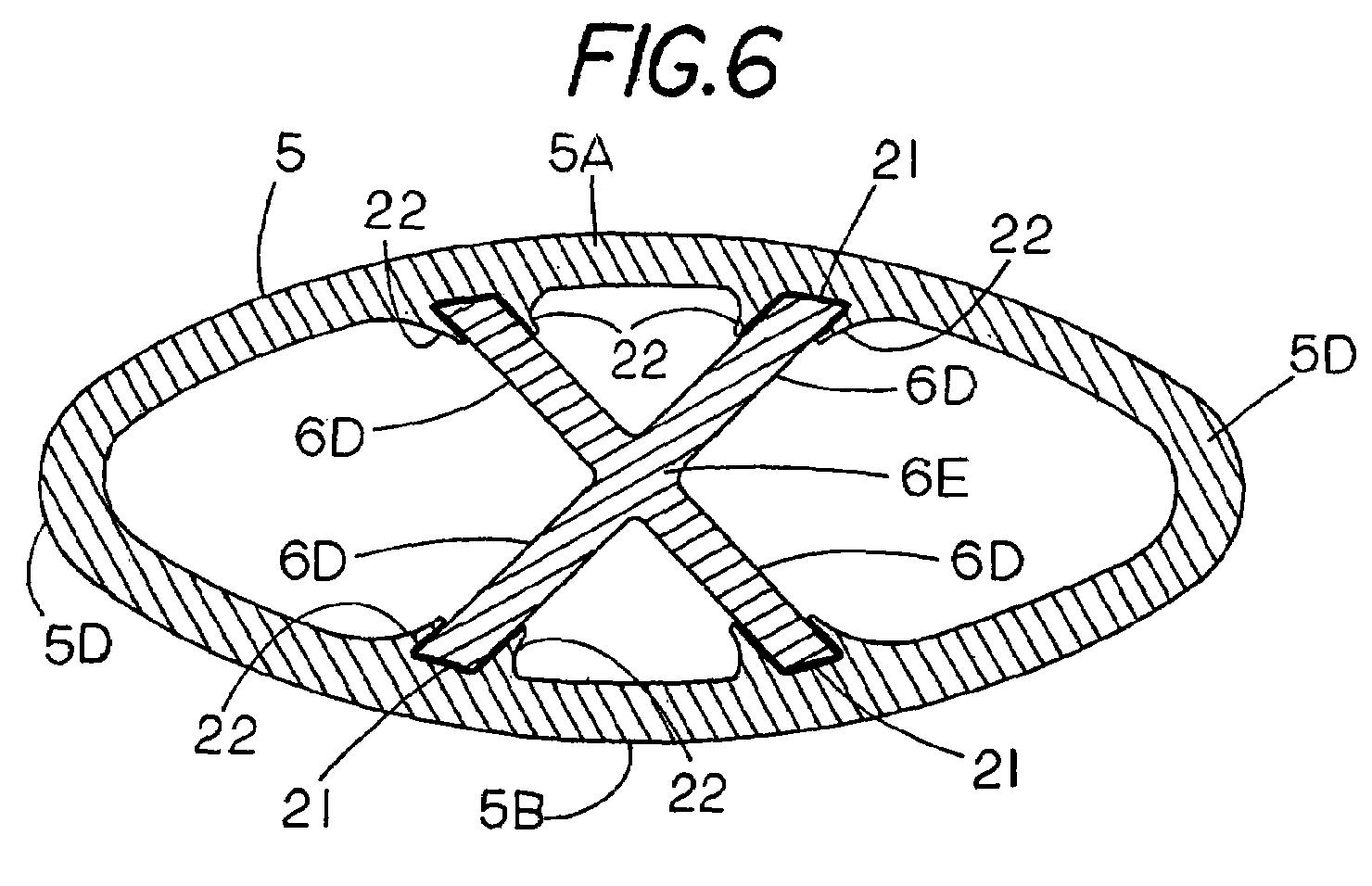

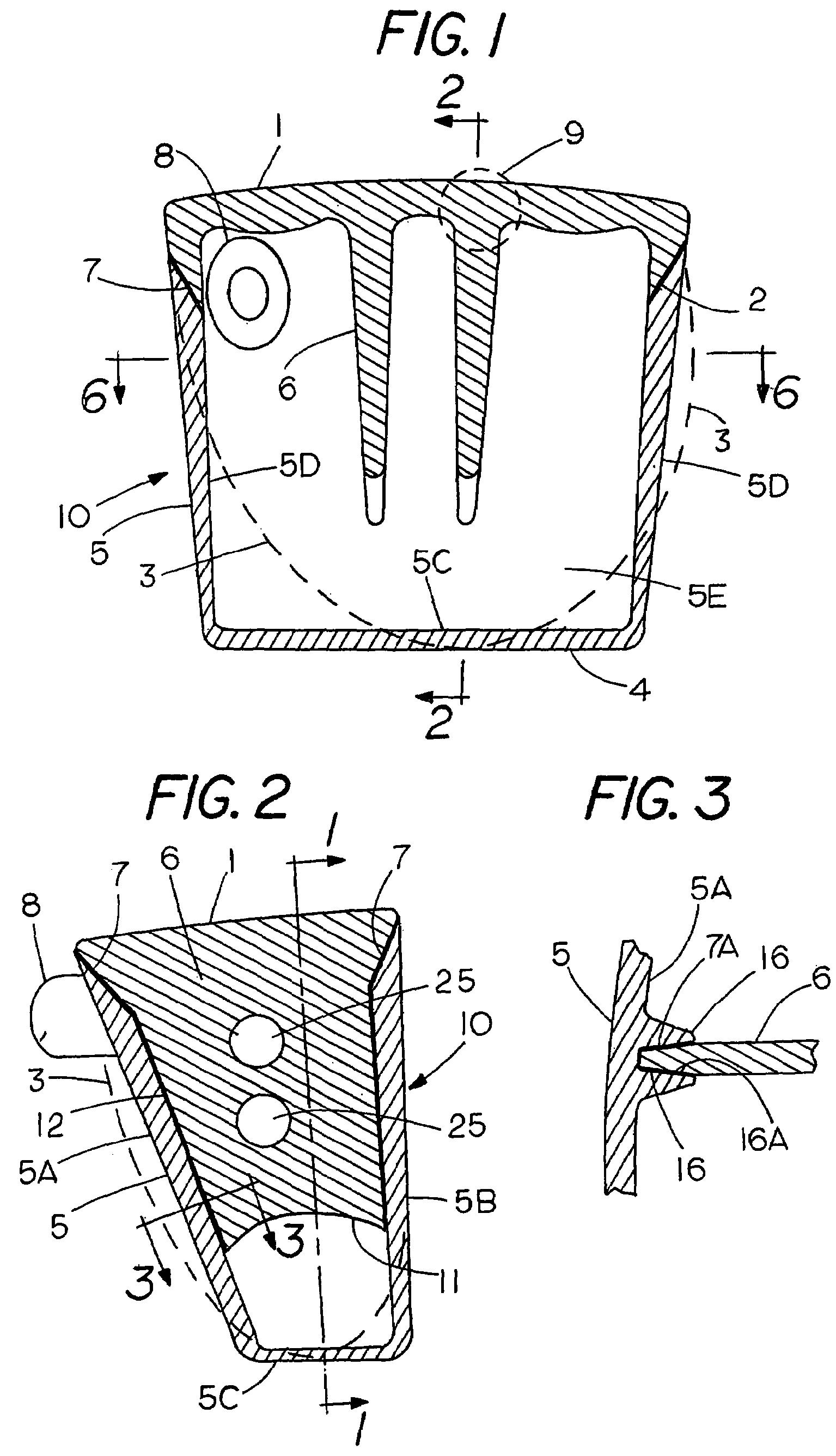

The present disclosure describes a design and assembly of wood-type golf club head parts that make it practical to manufacture golf club heads of large size that are primarily composed of strong plastic materials that in one aspect can be formed by plastic injection molding processes. The rear components of the club head (to the rear of the ball striking face structures) are collectively referred to as the “shell” in this disclosure. The shell includes the extreme rear part and what is commonly called the sole and crown of the club head. The front structure for hitting the ball is called the “face structure” and this face structure includes, and is preferably integral with, an “internal structure.” The structures are bonded together. The internal structure is composed of one or more parts, called “plates.” As shown, the plates are planar walls on the shell interior. A hosel structure and the mounting structure for the hosel are shown only schematically and can be formed as desired.The present design makes use of component parts that allow a “spring effect” of the club head within the limits established by the United States Golf Association (USGA). The USGA “pendulum test” is described in the publication of the USGA entitled “Procedures for Measuring the Flexibility of a Golf Club Head” Revision 2.0, Mar. 25, 2005, the test measures the characteristic time of the golf club head. The characteristic time is the contact time between a pendulum having a mass that strikes the face center of the golf club head held in a test apparatus and the face surface of the golf club head. The contact time upper limit is 239 microseconds with a test tolerance of 18 microseconds. The USGA states that this characteristic time is indirectly related to flexibility of the golf club head and corresponds to a coefficient of restitution (COR) of 0.822 with a test tolerance of 0.008.

The present design allows injection molding each of the two or more parts for the head in a mold having as few as two parts. These two mold parts are called the “cavity” and the “core” in this disclosure. Molding draft is provided on the parts to permit withdrawal of the core and cavity from the molded part. Strong plastics that may contain chopped fiber reinforcement may be injection molded. While injection moldable components are not as strong as laminated long fibers, pre-impregnated with plastic resin (pre-preg plastics), the pre-preg plastics are not injection moldable, and thus more difficult to form. The club head of this disclosure can provide the desired spring effect. A preferred plastic is polycarbonate with or without chopped fiber filler.

It is desired to make club head designs that are easier to injection mold, and wherein the head components are more efficient to assemble. It is also desired that the club head provides the modern spring effect when the club head strikes the ball. Since the present club head has efficient stress distribution it will permit all-plastic large size heads, as is desired, with acceptable club head weight. A molded club head, as disclosed, will minimize or eliminate the need for external finishing such as grinding, painting, and labeling. The present club head provides bond joints of adequate area to join injection molded components of a golf club head that has a spring effect when assembled.

Check out this design….

I would love to hear the sound of a plastic driver.

Dave Dawsey – Tracking Golf Patents

PS – click HERE to check out interesting putter posts