Want to Reduce the Scatter of Your Tee Shots? Author of Several Golf Club R&D Books Receives Interesting Elastic Club Head Patent That May Help Out

Are you familiar with Dr. Frank D. Werner? He is the author of a handful of books (example 1, 2) on golf club engineering, and was one of the early supporters of square drivers (see THIS prior post). Based upon his bio, I would bet that Frank is one smart guy.

Well, Frank was recently granted an interesting patent; namely, USPN 7510486 titled “Elastic Head Golf Club.” As you can imagine, the title caught my attention. The patent describes the invention as:

A golf club head, more specifically a driver head, has a shell structure aft of the face that has ample strength but also can deform in the fore-aft direction for off-center hits sufficiently to provide good spring effect for such hits, comparable to hits at the center. Unwanted scatter caused by off-center hits is reduced with the spring design used in the shell structure. The shell structure can be applied to other hollow wood-type club heads. The shell structure can be provided with a coat or cover to close openings in the shell structure, and selected to make little change in stiffness or mass of the shell.

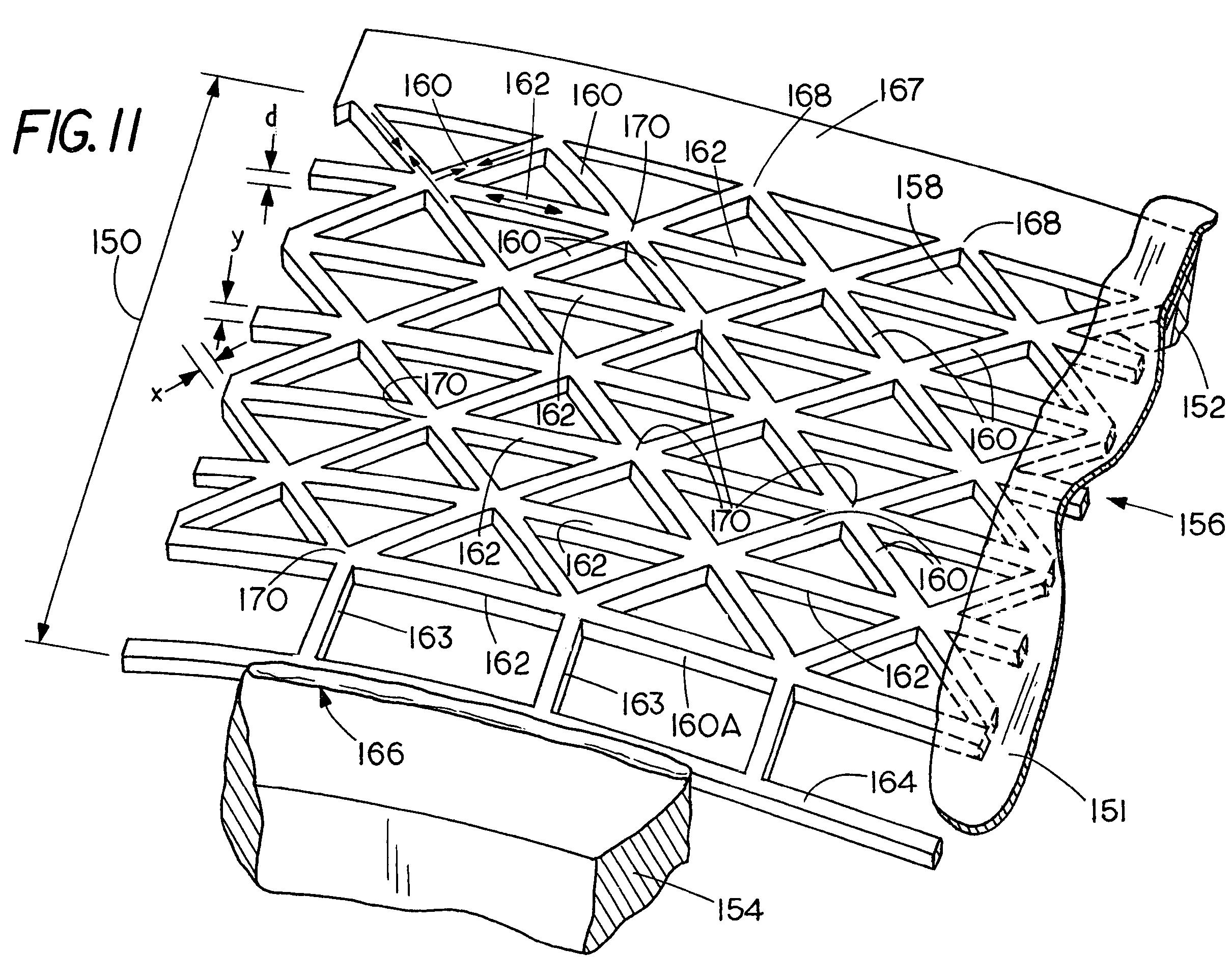

Check out this design….

The patent goes on to explain:

BACKGROUND OF THE INVENTION

Golf clubs and particularly the driver have been modified in recent years to have a so-called “spring effect.” The spring effect is such that the hitting surface (called “face”) is made to be less stiff and rigid than earlier designs. Upon head-ball impact near the face center, the face deflects within its elastic limit and it has been found that if this spring effect is optimized, the ball will travel some 5 to 15 yards farther than for previous designs. Hits that are somewhat off center do not fully realize this spring effect. As a result, in common terminology, this means the size of the “sweet spot” is undesirably small. A co-pending patent application Ser. No. 10/210,329, filed Aug. 1, 2002, shows that the rear part of the club head, called the “shell”, may be made to have much less stiffness than usual designs. The shell can thus combine with flexibility of the face so that this spring effect is also at least partly experienced by hits that are off center, meaning near the perimeter of the club face. The present invention describes an unusual mechanical design for the shell walls such that a metal shell can be made to have reduced stiffness to the desired degree. This is an important advantage because ordinary designs of metal shells having the desired stiffness would require corrugations or other features and would have more weight than can be tolerated. If made very long in the front-back dimension of the club head, a metal shell of conventional nature would be far too long for all known metals for the desired front-to-back stiffness.

The co-pending patent, Ser. No. 10/210,329, filed Aug. 1, 2002, describes a club head shell structure having acceptable weight and acceptable stiffness for hits away from the face center and particularly for hits near the perimeter of the face. One way this is achieved is by use of plastic material for the shell such as polycarbonate. It has low enough stiffness in compression for the purpose without excessive weight. It describes other ways of providing the desired stiffness, not like the present invention.

Bridge trusses and similar trusses used as floor beams are similar to the present invention in that they can store potential energy mainly in uniform compression or tension in the elements. They differ in that whereas the present invention uses a multiplicity of related structures in the direction of the applied load, trusses have no reason to have 2 or more truss structures acting on each other in the direction of the applied load. Such trusses also are more concerned with achieving high rigidity with minimal deformation under load, whereas the present invention is strongly concerned with relatively large deformation. Such trusses are not made from one piece of material, whereas this is a preferred method of construction of the present invention.

A fundamental comparison with prior art springs in general is the storage of energy per unit weight of the structure. As applied to a material having uniform stress at the elastic limit, the elastic energy stored in a cubic inch of material is sometimes called the “modulus of resilience” or as the “unit resilience”. It varies in the structure as the local stress varies and may be measured as elastic energy stored per unit weight or per unit volume. Various references such as the 8th edition of Mark’s “Standard Handbook for Mechanical Engineers” show resilience for beams in bending, coil springs, and numerous other structural configurations that have non-uniform stresses. For a given value of maximum stress, they store from as little as 1/12th to 1/2 as much energy per unit weight as the case of uniform tension or compression stresses (stresses that do not vary over the cross section considered). The preferred form of the present invention stores nearly as much energy as for uniform tension or compression. The result is substantial weight reduction for the novel spring over prior art.

SUMMARY OF THE INVENTION

The present invention is for a spring-like club head shell. It is primarily intended for “woods” and particularly for drivers. The preferred version causes the spring material to be primarily in either uniform compression or uniform tension. All ordinary springs have part of their structure that has little or no stress such as material near the center of the wire in coil springs. These parts add weight (more properly called “mass”) and contribute little to the strength and stiffness. The preferred version of the present invention has nearly all of its material contributing to the spring effect with relatively little of the material having low stress. Another way to state this advantage is that the novel design can store more potential energy (or elastic energy) per unit of weight than conventional springs, and particularly those for designs suitable for the shell of a driver. We refer to it as a “shell spring”

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

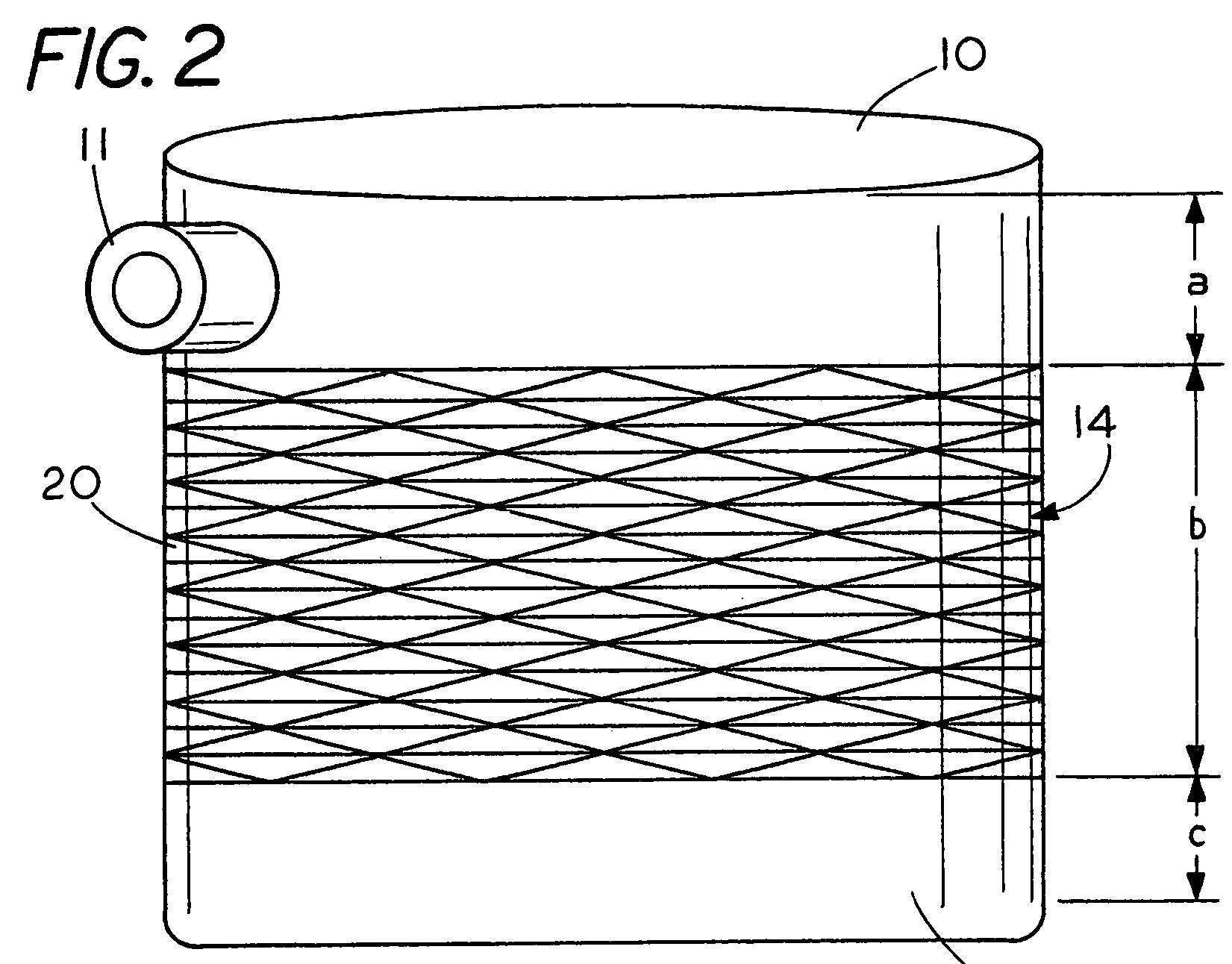

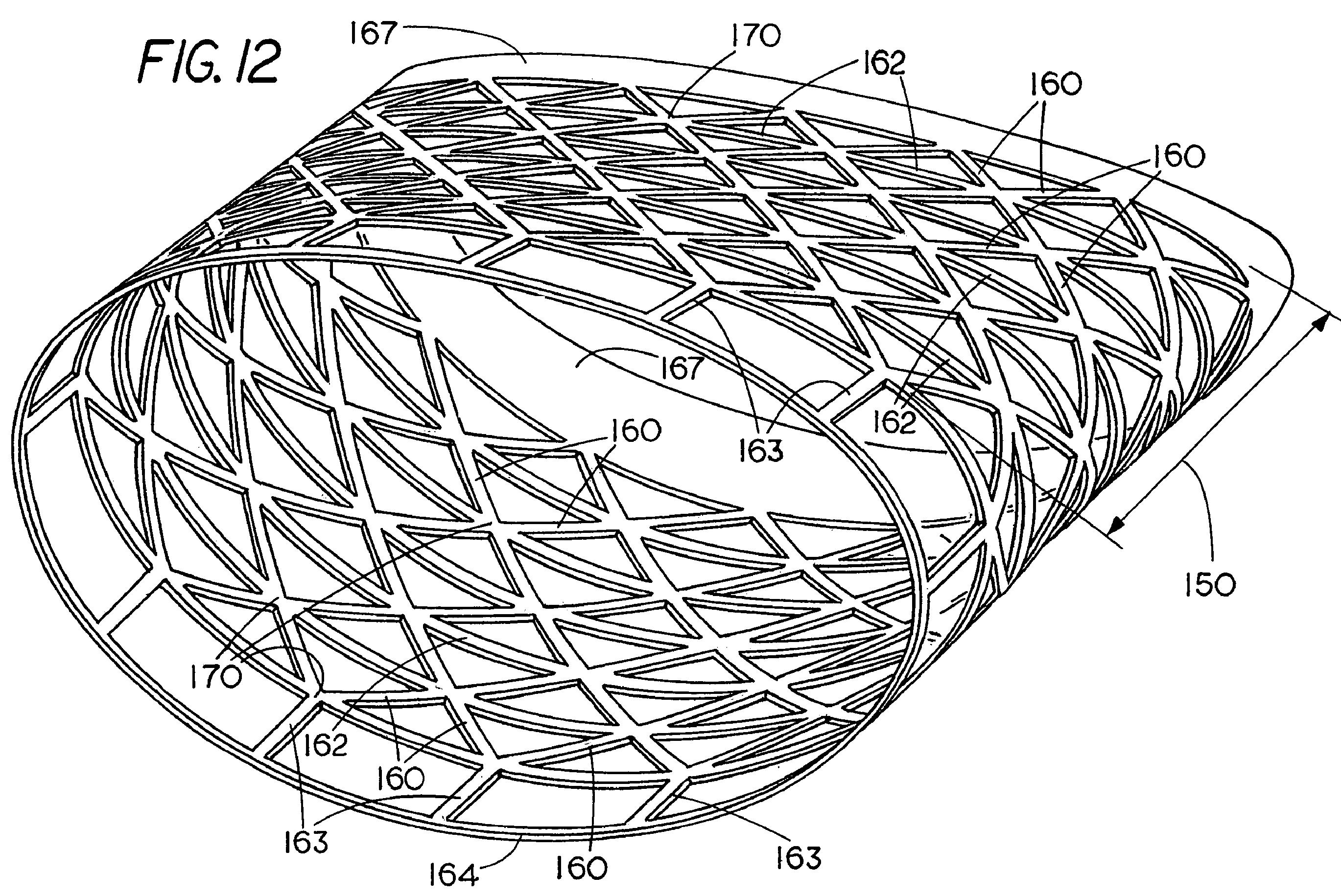

An unusual shape of a driver head is shown in FIGS. 1, 2 and 3. It has a face or “hitting face” labeled 10 in FIGS. 1 and 2. FIG. 3 shows a rear view. The parts aft of the face are labeled a, b, c, and 30 and collectively, are called the “shell”. The portion labeled b and 14 is a novel elastic part of the shell called the “shell spring”. Part a connects the shell spring to the face. Rearward from the shell spring is the “rear structure” 30 in FIG. 2. It is composed of the “rear plate” whose outline is labeled 31 together with part c called the “rear strap” which connects the shell spring to rear plate 31. The outline shape of rear plate 31 is rat

her arbitrary and a more preferred shape is shown in FIG. 12. The size and shape of the shell of FIG. 2 provides significantly larger moments of inertia and allows better design control of the center of gravity location than conventional driver head shapes. The present invention can also be applied to club heads of more conventional shape. The shell spring 14 is shown in “line” illustration and can have open or uncovered openings as shown, or may have openings covered with a shell or panel or coat of material having very low stiffness compared to stiffness of the shell spring, and very low weight.The shell spring deforms upon impact with a golf ball, particularly if impact is off center such as near the perimeter of the face. The spring effect at impact for off-center hits is much reduced in conventional designs of faces having the spring effect together with a relatively stiff shell, but the spring effect is reduced much less for such hits by the present invention. In addition, such impacts locally alter the slope of the face and cause errors in the direction of the shot for conventional spring effect club heads. The present invention improves the spring effect for such hits and also can reduce the change of slope of the face surface. These results are realized by allowing the edge of the face near such impacts to deform much more than is possible by conventional designs.

Great stuff, but will this elastic golf club make it to market?

Dave Dawsey – Tracking Golf IP

PS – click HERE to check out interesting putter posts