Not Enough Spin? Forget About Grooves and Look at the Ball

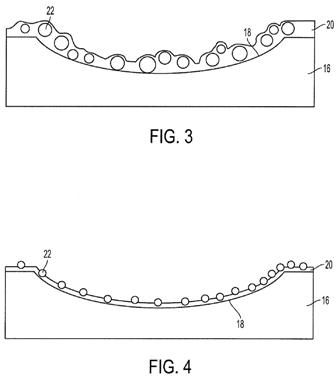

[0072] If the resin contains the particles, after the resin is applied to the golf ball body to form the coating, the particles may protrude beyond an average thickness of the resin. In some instances, the average size of the particles may be greater than the average thickness of the resin. As shown in FIG. 3, generally the particles 22 protrude from the surface such that a thin portion of the resin 20 still covers the particles. The surface of the ball will therefore be roughened somewhat, as shown in FIG. 3.

[0073] If the resin itself does not contain the particles necessary to provide the roughened surface when it is applied to the golf ball cover 18, after the resin is applied, and prior to drying, particles may be applied to the wet resin. The particles may adhere to and/or become embedded into the resin, but still extend from the surface of the resin to provide a somewhat roughened surface. As shown in FIG. 4, in this example structure and method, particles 22 are applied to the surface of resin 20.

[0074] The particles allow for fine tuning of and improvement on the aerodynamic performance of golf balls in flight, e.g., to enable longer flights of the golf ball. The particles cause the finish of the coating to be rougher and on a micro-scale act as small dimples, which increase the turbulence in the air flow around the ball and reduce flow separation on the golf ball, reducing pressure drag. Also, if desired, the durability of the golf ball may be improved both in cut resistance and abrasion resistance, e.g., depending on the properties of and/or materials used in the coating.

[0075] Given the general description of various example aspects of the invention provided above, more detailed descriptions of various specific examples of golf ball structures according to the invention are provided below.

II. DETAILED DESCRIPTION OF EXAMPLE GOLF BALLS, AND METHODS ACCORDING TO ASPECTS OF THE INVENTION

[0076] The following discussion and accompanying figures describe various example golf balls in accordance with aspects of the present invention. When the same reference number appears in more than one drawing, that reference number is used consistently in this specification and the drawings to refer to the same or similar parts throughout.

[0077] FIG. 3 and FIG. 4 demonstrate aspects of the invention related to golf balls having a top coat or other coating comprising resin and particles contained within the resin or applied and/or embedded thereon, respectively.

[0078] The particles may be of any shape and may be regular, irregular, uniform, non-uniform, or mixtures thereof. The particles may be any polygon or geometric shape, including regular shapes, such as spheres or cubes. The spheres may have a round cross-section or may be flattened to provide an elongated or oval cross-section. The cubes may be of square or rectangular cross-section. Irregular shapes may be defined by an irregular surface, an irregular perimeter, protrusions, or extensions. The particles may be rounded, elongated, smooth, rough, or have edges. Combinations of different shapes of particles may be used. Crystalline or regular particles such as tetrapods may also be used.

[0079] Particles may be made from any material known in the art, such as organic or inorganic, plastics, composite materials, and metals. Suitable particles include, but are not limited to amorphous particles such as silicas and crystalline particles such as metal oxides, e.g., zinc oxide, iron oxides, or titanium oxide. As additional examples, particles may comprise fumed silica, amorphous silica, colloidal silica, alumina, colloidal alumina, titanium oxide, cesium oxide, yttrium oxide, colloidal yttria, zirconia, colloidal zirconia, polyethylene terephthalate, polybutylene terephthalate, polyethylene naphthalate, vinyl esters, epoxy materials, phenolics, aminoplasts, polyurethanes and composite particles of silicon carbide or aluminum nitride coated with silica or carbonate.

[0080] The particles may be selected to fine-tune the roughness of the golf ball to achieve the desired aerodynamic qualities of the golf ball as well as to improve abrasion resistance. The particles may by of any suitable hardness and durability. Softer particles tend to affect spin, for example.

[0081] The average size of the particles depends on the material selected for the particles. Generally, the particle sizes will range from 400 nm to 40 microns, and in some example constructions, from 5 to 20 microns. In one particular example, the particle sizes range from 8 to 12 microns. The particles may be approximately the same size or may be different sizes within the defined ranges. If the particles are applied to the surface of the resin, they would generally be smaller than if they were contained within the coating.

.

.

.

[0089] In one aspect the coating comprises resin (with any additives) and particles mixed therein. The coating is applied to the golf ball body such as described above. Prior to application to the golf ball body, the particles may be added to the resin as a separate ingredient, or may be pre-mixed with one of the components in a two-component coating composition.

[0090] In another aspect, a resin layer (with any additives) is applied to the golf ball body such as described above. Prior to drying, particles are applied to the top of the wet resin layer using a media blaster, sand blaster, powder coating device, or other suitable device. The particles may adhere to the surface and/or be embedded into the surface of the resin layer.

[0091] In another aspect, a very thin resin layer may be applied on top of the particles to hold the particles in place. Generally this resin layer is composed of the same resin layer initially applied, but may have

a thinner viscosity. This additional thin layer of resin may be provided, if necessary or desired, to fine tune or somewhat reduce the exterior surface roughness of the ball.

.

.

.

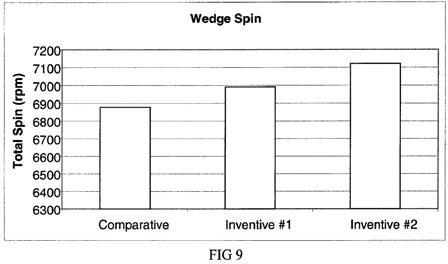

[0098]The spin graphs (FIGS. 7-9) show the inventive coating can increase spin off of irons and wedges without increasing driver spin. This is advantageous for more distance off the drive (lower spin) and more control around the green (higher spin).

Looks like I will be taking a can of hairspray to the course this weekend and roll my ball around in the sand after a fresh coat!

David Dawsey – Keeping an Eye on Golf Ball Technology

PS – click HERE to read more interesting golf ball patent posts