MOI Was the Buzz Word for Driver Marketing a Few Years Ago; Will it become a Golf Ball Buzz Word?

Three years ago I wrote about an interesting variable MOI driver design disclosed in a Karsten (aka PING) patent application (read about it here); but this week I want to examine what Acushnet has in mind for a variable MOI golf ball. Yep, you read that correctly, a variable MOI golf ball!

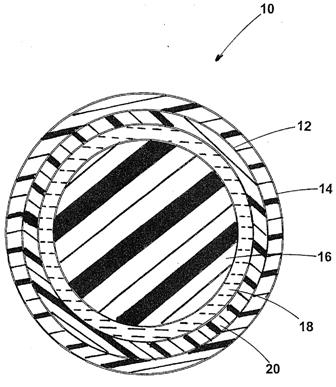

An Acushnet patent application recently published as US Pub. No. A golf ball having a core that includes an aqueous solution contained by a boundary layer with a solid center suspended in the solution to modify the moment of inertia of the golf ball. The aqueous solution can be thixotropic, or rheopectic, or dilatant, or pseudoplastic in nature and the center formulated to simulate the specific gravity of the solution.

Get past all the words that most of us can’t pronounce let alone spell and there is some interesting disclosure in the application. For instance….

BACKGROUND OF THE INVENTION

[0002] Generally, golf balls have been classified as solid balls or wound balls. Solid balls are generally classified as two, three, or four piece balls. Two piece balls are comprised of a solid polymeric core and cover. These balls are generally easy to manufacture, but are regarded as having limited playing characteristics. Three and four piece balls are comprised of a solid or liquid filled center surrounded by tensioned elastomeric material and a cover. Three and four piece balls generally have a good “click” and “feel” when struck by a golf club, but are more difficult to manufacture than two piece balls.

[0003] The prior art is comprised of various golf balls that have been designed to provide optimal playing characteristics. These characteristics are generally the initial velocity and spin of the golf ball, which can be optimized for various players. For instance, certain players prefer to play a ball that has a high spin rate for playability. Other players prefer to play a ball that has a low spin rate to maximize distance. The ideal ball has low spin when struck with the driver and high spin when landing on the green.

[0004] The prior art is also comprised of various liquid filled golf balls. Wound golf balls have been made with liquid centers for many years. U.S. Pat. Nos. 1,568,513 and 1,904,012 are directed to wound golf balls with liquid filled centers. U.S. Pat. Nos. 5,150,906 and 5,480,155, are directed to a hollow spherical shell of a polymeric material which is filled with a liquid or unitary, non-cellular material that is a liquid when introduced into the shell. The shell is disclosed as being the outer cover or an inner layer with the outer cover formed to the external surface thereof. The shell varies in thickness from about 0.060 to 0.410 inches in thickness.

[0005] The Rules of Golf as approved by the United States Golf Association (USGA), include the following rules that relate to golf ball construction:

[0006] a. Weight: The weight of the ball shall not be greater than 1.620 ounces avoirdupois (45.92 gm).

[0007] b. Size: The diameter of the ball shall be not less than 1.680 inches (42.67 mm). This specification will be satisfied if, under its own weight, a ball falls through a 1.680 inches diameter ring gauge in fewer than 25 out of 100 randomly selected positions, the test being carried out at a temperature of 23+/-1.degree. C.

[0008] c. Spherical Symmetry: The ball must not be designed, manufactured or intentionally modified to have properties which differ from those of a spherically symmetrical ball.

[0009] d. Initial Velocity: The velocity of the ball shall not be greater than 250 feet (76.2 m) per second when measured on apparatus approved by the United States Golf Association. A maximum tolerance of 2% will be allowed. The temperature of the ball when tested will be 23+/-1.degree. C.

[0010] e. Overall Distance Standard (ODS): A brand of golf ball, when tested on apparatus approved by the USGA on the outdoor range at the USGA Headquarters under the conditions set forth in the Overall Distance Standard for golf balls on file with the USGA, shall not cover an average distance in carry and roll exceeding 280 yards (256 m) plus a tolerance of 6%.

[0011] The flight of a golf ball is determined by many factors, but only three factors that are typically controlled by the golfer. By impacting the ball with a golf club, the golfer typically controls the speed of the golf ball, the launch angle and the spin rate. The launch angle sets the initial trajectory of the golf ball’s flight. The speed and spin of the ball give the ball lift which will define the ball’s overall flight path along with the weight and drag of the golf ball. Where the ball stops after being struck by a golf club depends greatly on the weather and the landing surface the ball contacts.

[0012] Many golfers have what is termed a “low swing speed.” This means that the club head speed at impact is relatively slow when compared to a professional golfer. Typically, when driving a golf ball the average professional golf ball speed is approximately 234 ft/s (160 mph). A person having a low swing speed typically drives the ball at a speed less than 176 ft/s (120 mph). Upwards of thirty percent of all golfers today have swing speeds that produce drives of less than 210 yards. A person with a low swing speed has a low ball speed. His or her ball does not fly very far because of the lack of speed and lift. No matter what a golfer’s swing speed, every innovative idea seeks to reduce a golf ball’s downrange spin, while enhancing spin once the ball lands on the green. The present invention seeks to achieve this by modifying the golf ball’s moment of inertia/radius of gyration.

.

.

.

DESCRIPTION OF THE PREFERRED EMBODIMENT[0020] Referring to the drawing, a ball 10 includes a core 12 and a cover 14. The golf ball’s moment of inertia/radius of gyration is modified by the core 12 having a mechanically decoupled center 16 suspended in a thin layer of an aqueous solution 18 contained within a boundary layer 20. The center 16 may be formulated to match the specific gravity of the aqueous boundary layer 18, therein minimizing any settlement of the center 16 within its liquid suspension. It is anticipated that the aqueous solution is non-Newtonian and can be selected from: thixotropic, wherein the apparent viscosity decreases with the duration that it is put under stress; or rheopectic, wherein the apparent v

iscosity increases with the duration of stress. Both of these are time-dependent viscosities. Examples of rheopectic materials can be some lubricants or whipped cream. Examples of thixotropic materials would be clays, some drilling muds, and many paints. The non-Newtonian materials could also be selected from those materials in which the viscosities are independent of time such as dilatant materials (shear thickening), wherein the apparent viscosity decreases with the duration of the stress, or pseudoplastic (shear thinning) wherein the viscosity decreases with increased stress. Examples of dilatant materials are suspensions of corn starch, or sand in water, clay, gypsum paste, nano-cellulose, while examples of pseudoplastic materials are paper pulp in a water solution, latex paint, ice, blood, or surfactant/soap mixtures. While it is the intent for the invention to partner the center 16 with a non-wound construction, it is to be appreciated that this center construction may be applied to any golf ball in the prior art.[0021] By being suspended within the aqueous solution and being a solid mass the center 16 helps to create a stronger effect on the shift of moment of inertia (MOI), as a greater effort is required to bring the entire mass of the solid mass from rest to rotational motion.

Interesting for sure, but would such a ball be “conforming”?

David Dawsey – The Golf Invention Attorney

PS – click HERE to read more posts about golf ball inventions