Has the Golf Ball Dimple Reached the End of its Useful Life?

In the past the Golf-Patents blog has published many posts regarding the potential look of future golf balls (here, here, here, here, and here). It has gotten to the point that I am starting to believe that the day will come when I will tell young golfers that I remember playing golf with a ball that had dimples (round dimples at that) and they won’t believe me.

Supporting this belief is a patent that was granted to Acushnet today titled “Golf Ball Surface Textures.” The patent (USPN 7,588,505) describes the invention as:

A method for generating a textured surface for a golf ball is disclosed. Preferably, the textured surface of the golf ball substantially minimizes the drag experienced by the golf ball. The method includes generating a guide pattern. The guide pattern is preferably mapped to the surface of the golf ball. A shaped profile may also be generated. The textured surface of the golf ball may be generated based on sweeping the shaped profile along the guide pattern. It may be desirable to add protrusions or entrenchments to the surface of the golf ball to further reduce drag.

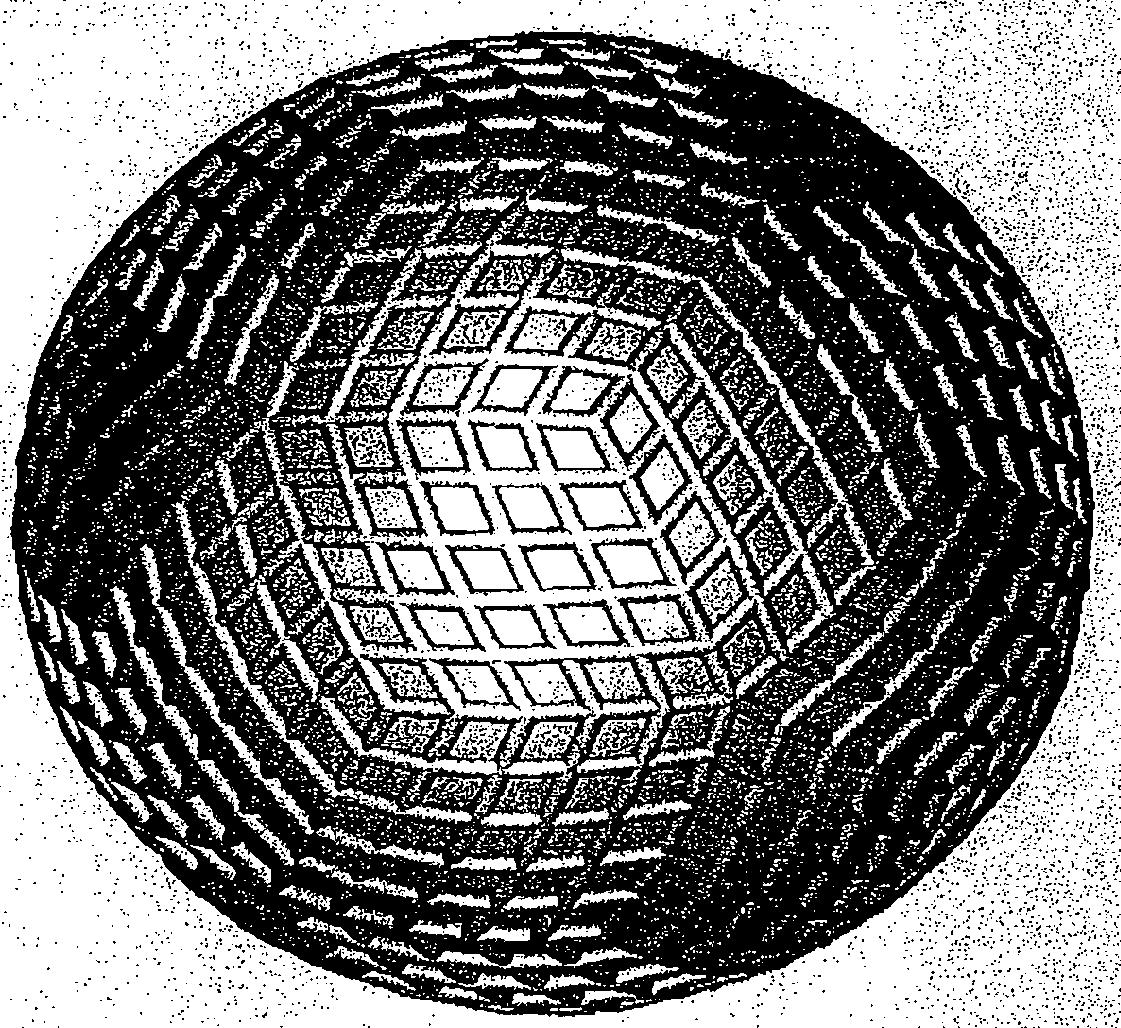

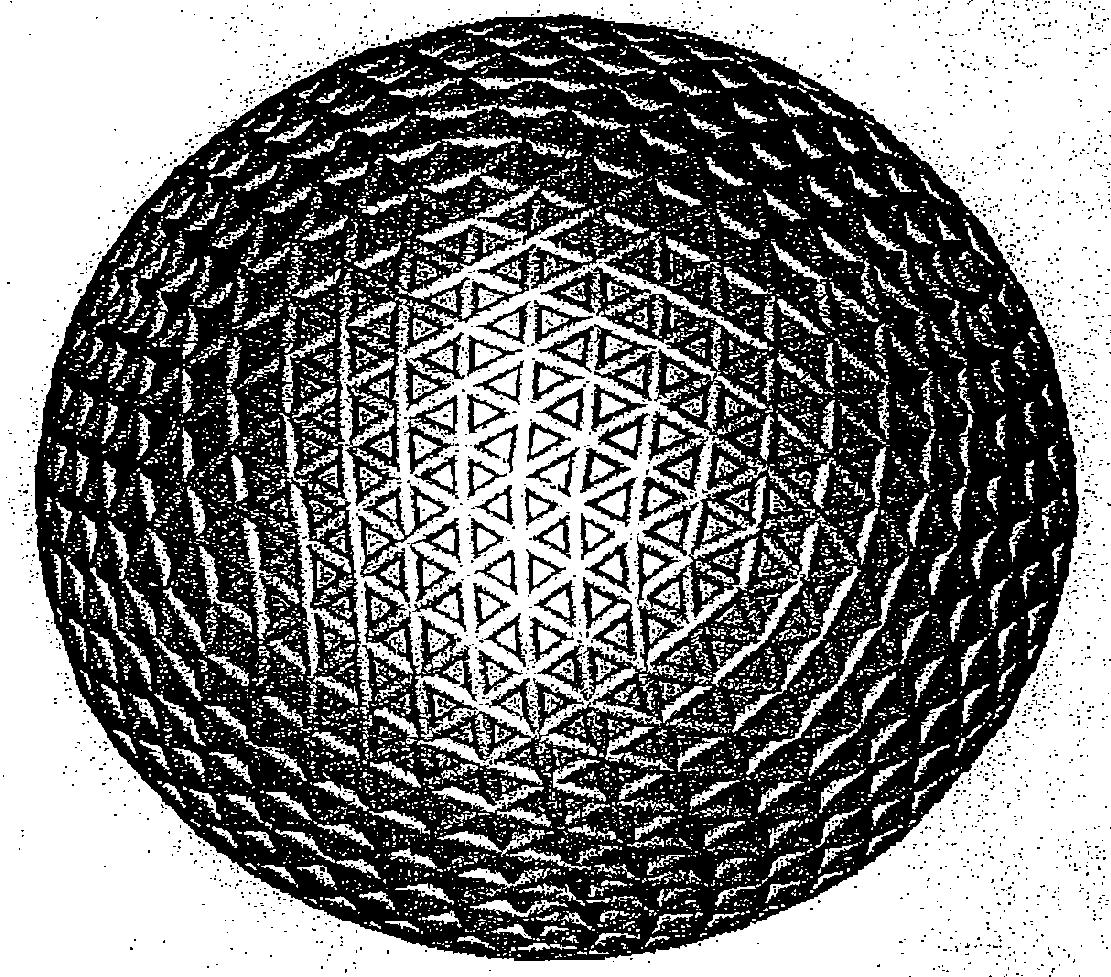

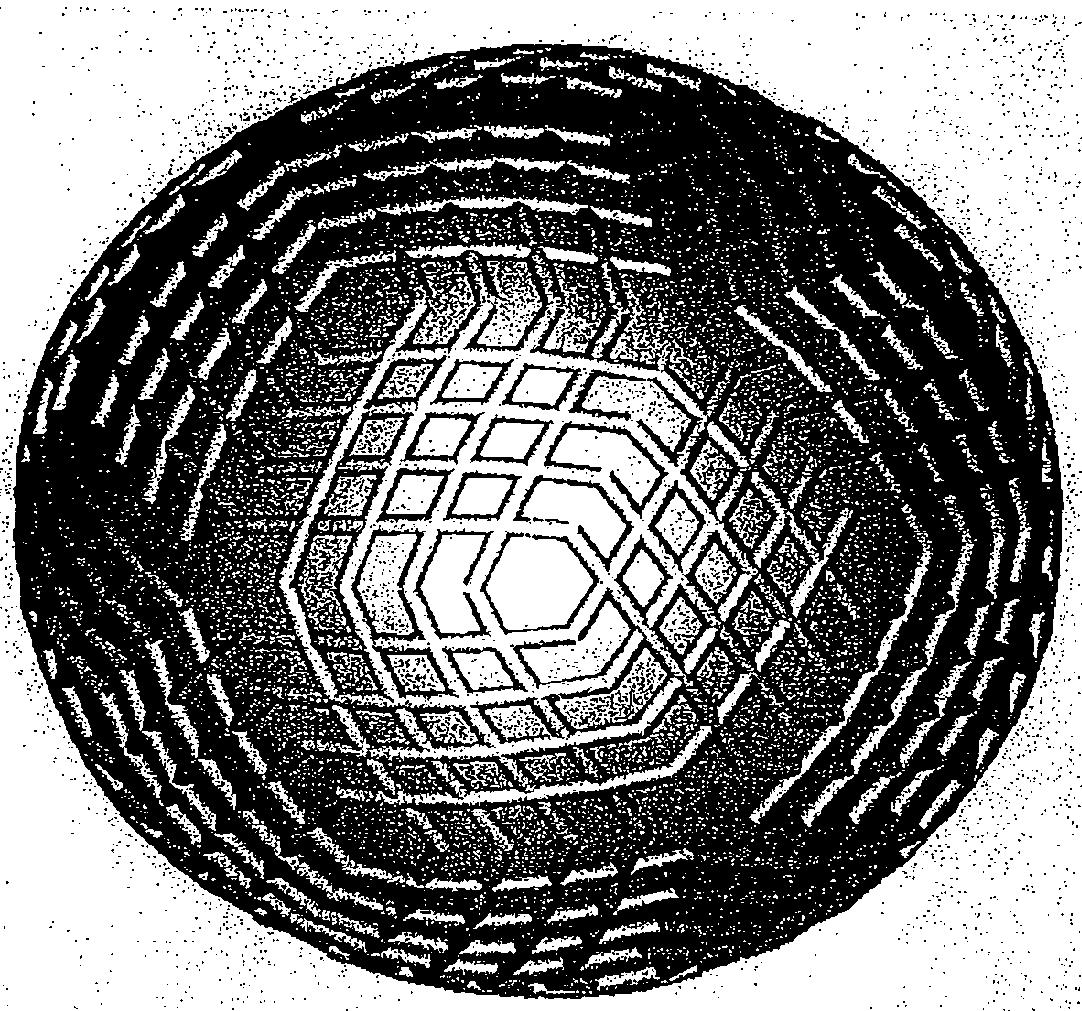

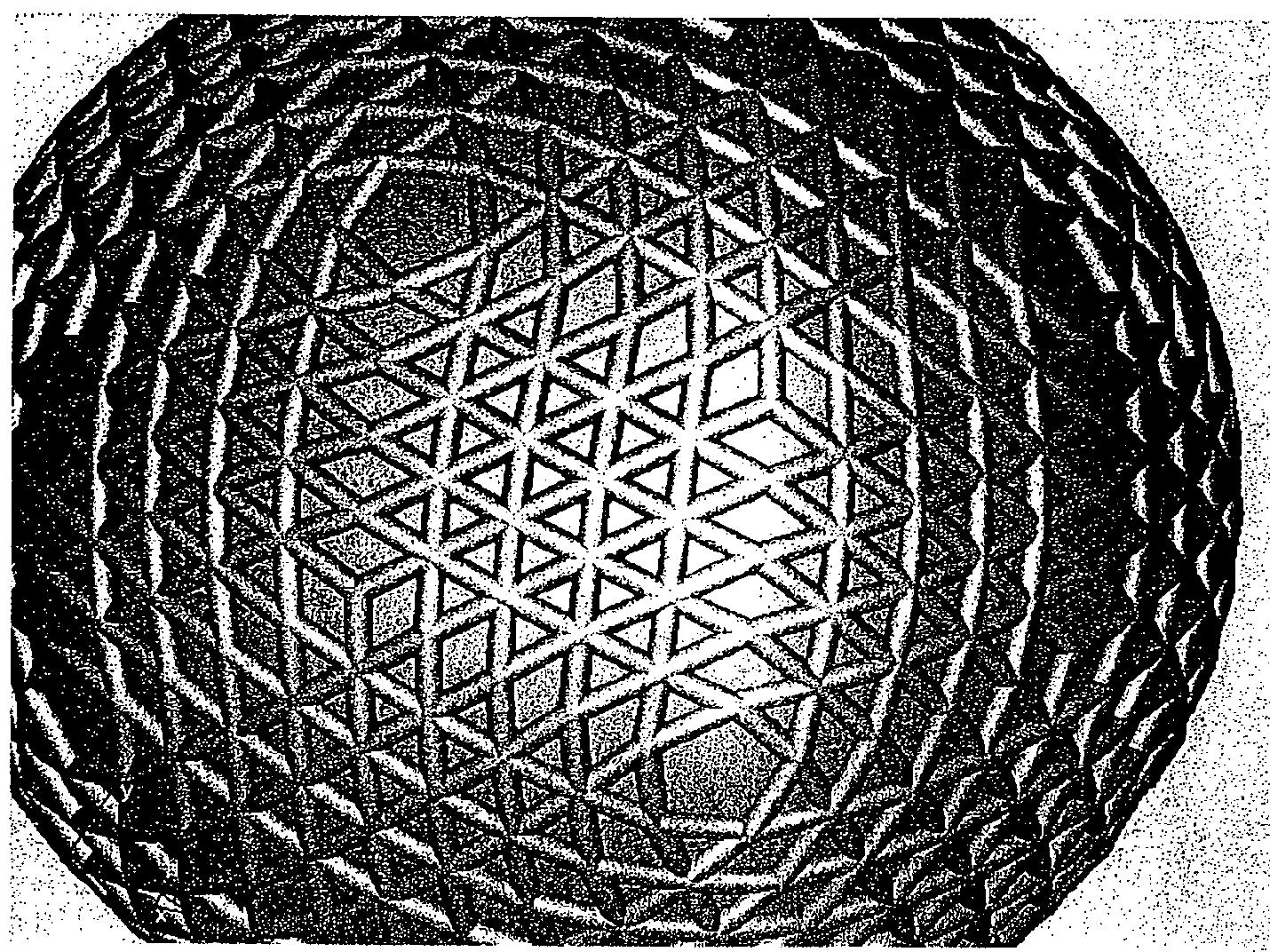

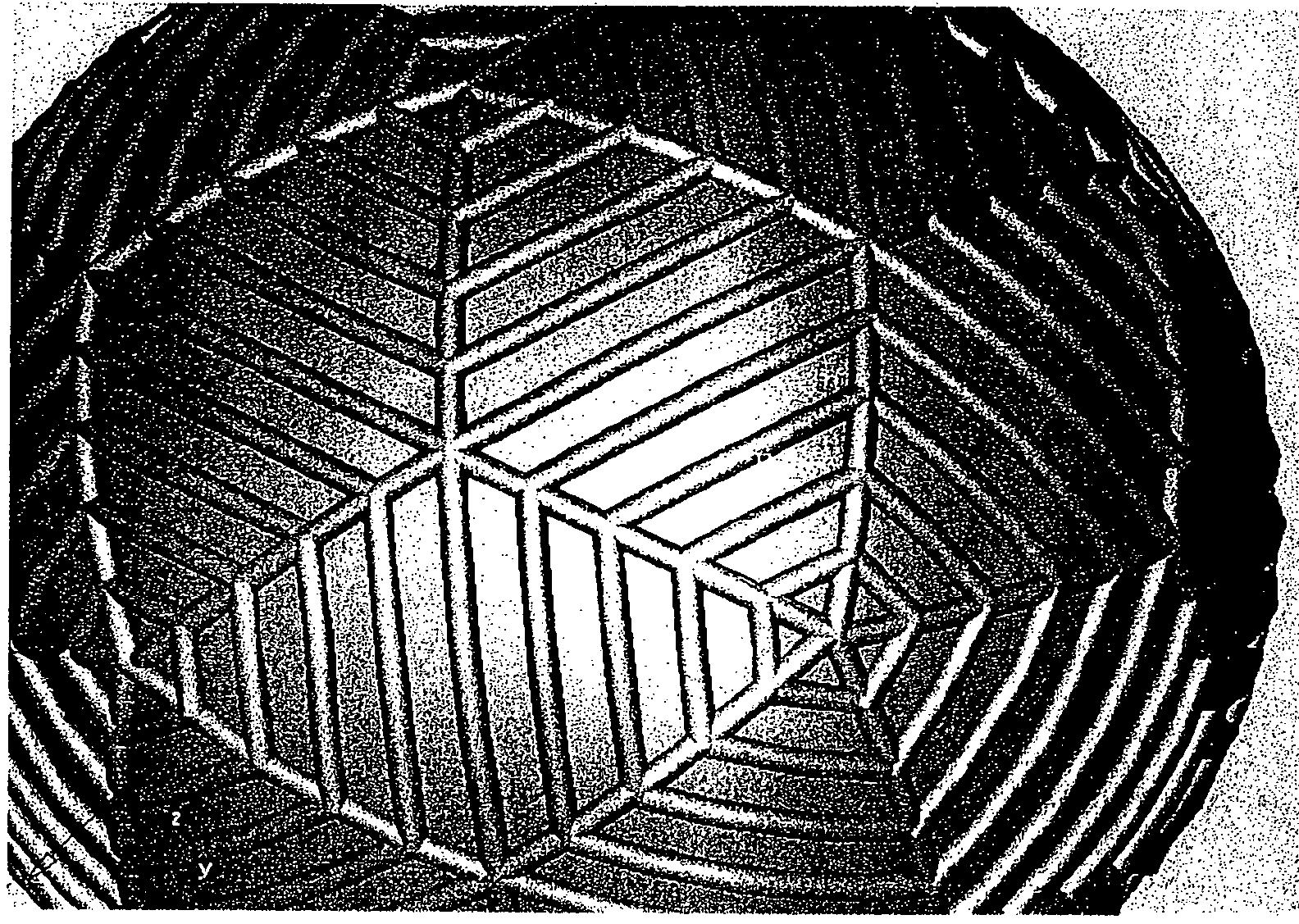

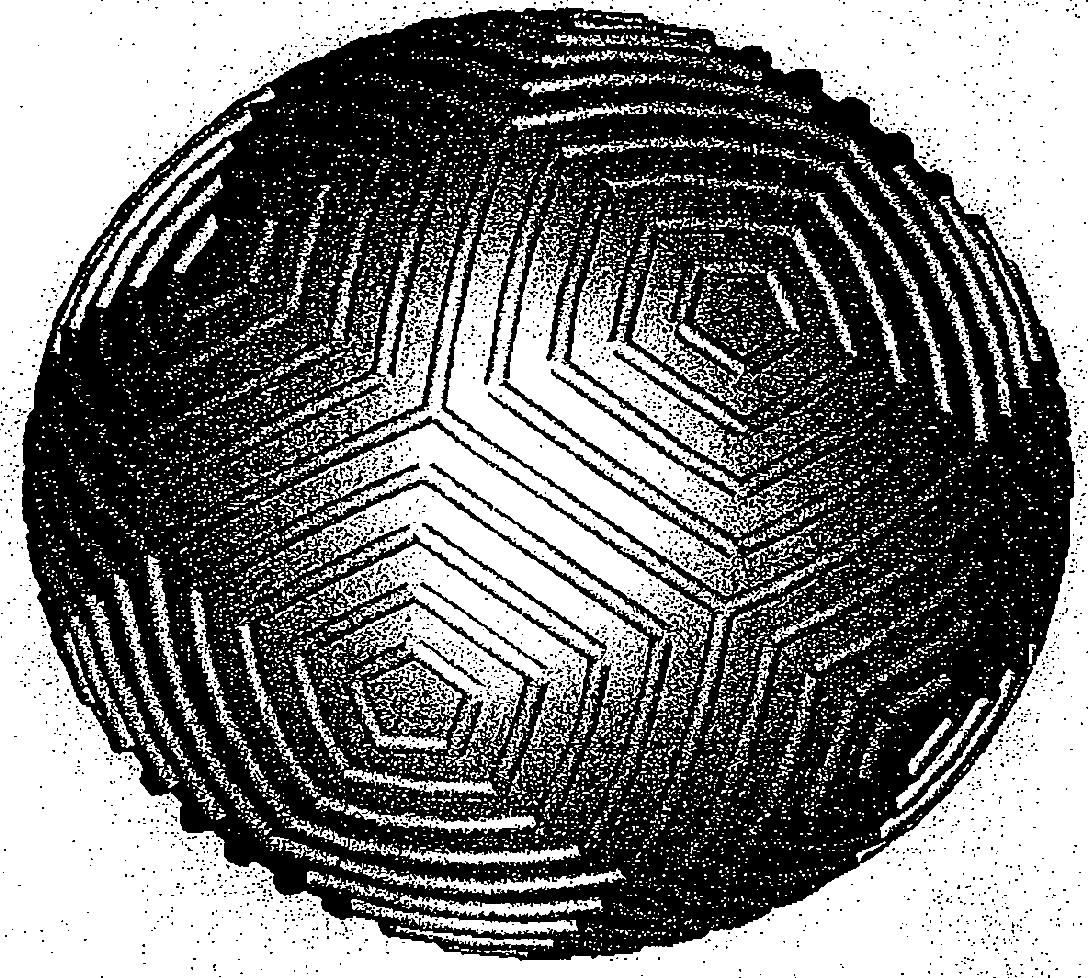

Check out these surface patterns!

The patent goes on to explain:

The early golf ball, known as a featherie, consisted of a leather pouch filled with goose feathers. In order to obtain a hard ball, the pouch was usually filled while wet with wet goose feathers. Since it was widely believed that a smooth sphere would result in less drag, and thus fly farther, the pouch was stitched inside out. Once the pouch was filled with feathers, it was stitched shut. In this manner, a golf ball could be constructed with few stitches on the outside of the ball. In many instances, the ball was then dried, oiled, and painted white. The typical drive with this type of ball was about 150 to 175 yards. However, once this ball became wet, it could no longer be used.

Around 1845, the gutta-percha ball was introduced. This ball was made from the gum of the Malaysian Sapodilla tree. Typically, the gum was heated and molded into a sphere, resulting in a very smooth surface. The typical drive with the gutta-percha ball was shorter than that obtained with the featherie. Around this time, many golfers began to notice that older balls that were beat up with nicks, bumps, and other surface irregularities seemed to fly farther. As golf balls evolved, golfers began to seek beat up golf balls because they provided an advantage over smooth balls.

As golf ball research progressed, manufacturers began to realize that including dimples on the surface of the golf ball would allow it to fly farther. The nicks and bumps of previous golf balls, and the dimples of modern golf balls, provide an aerodynamic advantage over a smooth surface. Engineers discovered that the dimples act as “turbulators” in the layer of air next to the ball (the “boundary layer”). In some situations, a turbulent boundary layer is capable of reducing drag, which in turn increases the distance that a golf ball is capable of flying.

The flow of air around an object may be described as laminar and turbulent. Laminar flow has less drag, but it is also susceptible to a phenomenon called “separation.” Once separation of a laminar boundary layer occurs, the drag rises dramatically because of eddies that form in the wake. Turbulent flow has more drag initially but also better adhesion, and therefore is less prone to separation. Therefore, engineers learned that if the shape of an object is such that separation occurs easily, it is better to perturb the boundary layer, at the slight cost of increased skin friction drag, in order to increase adhesion and reduce eddies. Typically, this means a significant reduction in drag. Thus, dimples are included on the surface of golf balls in order to perturb the boundary layer. Dimples on a golf ball are a symmetrical way of creating the same turbulence in the boundary layer that nicks and cuts did on previous golf balls.

Golf ball manufacturers are constantly searching for more efficient methods of changing the surface of a golf ball in order to reduce drag and thereby increase the distance that a golf ball is capable of flying.

SUMMARY OF THE INVENTION

According to one aspect of the present invention, the present invention comprises shaped profiles and predetermined guide patterns that may be generated using a processor based computer program or the like. It may be desirable for the processor to be capable of executing computer program instructions. In one embodiment, the processor may be operatively connected to, for example, a memory, user interface, display, and the like. Preferably, the processor is capable of running an operating system that supports a computer program that is capable of simulating the effect of dragging a plurality of different shaped profiles across different paths. It may be desirable for the processor to be capable of determining the drag that would result from different combinations of shaped profiles and guide patterns such that a golf ball manufacturer could use this calculation to choose combinations that result in optimal golf ball surfaces.

In one embodiment, the present invention comprises a method for forming a textured surface for a golf ball. The method includes generating a guide pattern, mapping the guide pattern to the surface of the golf ball, generating a shaped profile, and generating a textured surface for the golf ball based on sweeping the shaped profile along the guide pattern. The guide pattern comprises one of geometric patterns, fractal patterns, lines, and irregular patterns. Alternately, the guide pattern may be randomly defined. The shaped profile may comprise at least one of irregular shapes and regular shapes. In other embodiments, the shaped profile may comprise a smooth and continuous curve.

The guide pattern may be based on about 30 or more mathematical functions. In another embodiment, the guide pattern is based on between about 1 and about 30 mathematical functions. The textured surface may be based on, for example, between about 1 and about 25 guide patterns.

In one embodiment, the shaped profile comprises at least one of a spherical curve, Gaussian curve, Poisson curve, caternary curve, parabolic curve, and hyperbolic curve. Preferably, the shaped profile compri

ses a portion that is tangent to the spherical surface of the golf ball. According to one aspect of the present invention, more than one shaped profile may be swept along a guide pattern. A guide pattern may comprise a combination of two or more guide patterns. The two or more guide patterns are combined based on at least one of addition, subtraction, multiplication, division, or convolution. Protrusions or entrenchments may be added to the surface of the golf ball as desired.According to another aspect, the present invention comprises a method for defining a golf ball surface texture. The method includes generating a first guide pattern, mapping the first guide pattern to the surface of the golf ball, generating a first shaped profile, and sweeping the first shaped profile along the first guide pattern to define a first surface texture. The method further comprises generating a second guide pattern, mapping the second guide pattern to the surface of the golf ball, generating a second shaped profile, and sweeping the second shaped profile along the second guide pattern to define a second surface texture.

The present invention is also direct to a method for generating a textured surface for a golf ball that includes generating a plurality of guide patterns, mapping at least one of the plurality of guide patterns to the surface of the golf ball, generating a plurality of shaped profiles, and generating a textured surface for the golf ball based on sweeping at least one of the plurality of shaped profiles along at least one of the plurality of guide patterns.

Preferably, each of the plurality of guide patterns is mapped to a portion of the surface of the golf ball. Preferably, each of the plurality of guide patterns is mapped to less than about 60% of the surface of the golf ball. In another embodiment, each of the plurality of guide patterns is mapped to more than about 80% of the surface of the golf ball. Two or more of the plurality of guide patterns may overlap by a predetermined amount. The amount of overlap may be between about 0% and about 50%. Alternately, the amount of overlap is about 40% or more.

The patent goes on to explain:

Over the years, golf ball’s have evolved to include dimpled surfaces. The dimpled surfaces are typically used to reduce drag, thereby increasing the distance a golf ball is capable of flying. Although round dimples are used by most manufacturers, other shapes such as hexagonal, square, oval, and the like have been experimented with. The dimple depth, shape, and even the number of dimples have been modified in an attempt to reduce the drag on the golf ball as much as possible.

Manipulation of dimples, however, may eventually reach a point beyond which drag cannot be reduced further. Accordingly, other methods of reducing drag or increasing lift may be useful. The present invention provides a method for altering the texture of the surface of a golf ball that is capable of reducing drag on a golf ball during flight. The present invention is capable of achieving the reduction in drag by generating a golf ball surface texture based on sweeping shaped profiles across predetermined guide patterns on the ball’s spherical surface. Preferably, the reduction in drag may be achieved without using conventional dimples. However, it may be desirable to include protrusions or entrenchments on the surface of the golf ball after the shaped profiles have been swept across the predetermined guide patterns.

According to one aspect of the present invention, the shaped profiles and the predetermined guide patterns may be generated using a processor based computer program or the like. It may be desirable for the processor to be capable of executing computer program instructions. In one embodiment, the processor may be operatively connected to, for example, a memory, user interface, display, and the like. Preferably, the processor is capable of running an operating system that supports a computer program that is capable of simulating the effect of dragging a plurality of different shaped profiles across different paths. It may be desirable for the processor to be capable of determining the drag that would result from different combinations of shaped profiles and guide patterns such that a golf ball manufacturer could use this calculation to choose combinations that result in optimal golf ball surfaces.

In one embodiment, the present invention comprises a method for forming a golf ball surface texture that reduces drag. Preferably, the method includes determining a guide pattern to be mapped to the spherical surface of the ball. The guide pattern may have any desired shape. This may include, but is not limited to, geometric patterns, fractal patterns, irregular patterns, lines, and the like. In one embodiment, it may be desirable for the pattern to be a combination of at least two of geometric patterns, fractal patterns, irregular patterns, and lines.

Fascinating stuff!

So, how long do you think it will be before traditional circular dimples are obsolete?

David Dawsey – Keeping an Eye on Golf Ball Inventions

PS – click HERE to read more interesting golf ball patent posts