Golf Club Shaft Technology, The Least Understood Golf Technology

How well do you understand the technology behind golf club shafts? If you are like most golfers, then you might know a few buzz words like kick point, torque, and flex, but probably don’t understand the impact that various construction techniques have on a shaft’s properties.

This post is not intended to explain the ins and outs of shaft technology (after all, there are a lot of people infinitely more qualified than me to explain those things). However, click HERE to learn what those common buzz words actually mean.

This post is intended to introduce what may, or may not, be an interesting new shaft construction. The shaft construction is disclosed in a patent application that recently published as US Pub. No. 20080287212 titled “Golf Club Shaft and Method of Fabricating the Same.” The application explains:

[0004] A golf club generally includes a club head for making impact with a golf ball, a club shaft combined with the club head, and a grip. A carbon shaft formed of a carbon fiber material may be taken as a typical example of the golf shaft, and it is extremely light-weight while showing sufficient strength and elastic force. Typically, a shaft functions to deliver the energy of swing to the ball, and a golfer feels the impact through the shaft. A backswing and a downswing are usually finished within a very short time, for example, within only one second, and the speed of the shaft may be over 150 km/hr during the swing. It is known that, during the swinging process, the golf shaft may experience a large amount of stress and show a large degree of torque. In addition, by an impact with the golf ball, the head is withdrawn with respect to the shaft, and thereafter the shaft resonates forward and rearward.

[0005] With a typical carbon shaft, a large degree of torque results during the downswing and at the moment of impact, and accordingly it is difficult to hit the ball exactly in a desired direction. In addition, since the carbon shaft has a relatively small restoring force, a golf ball drive distance is limited.

[0006] Further, in order to reduce torque and twist and to increase strength, a typical carbon shaft is fabricated by wrapping carbon fiber fabric to form a plurality of layers. However, in this case, the weight of the carbon shaft increases, resulting in deterioration of an impact feel.

The application explains the invention as:

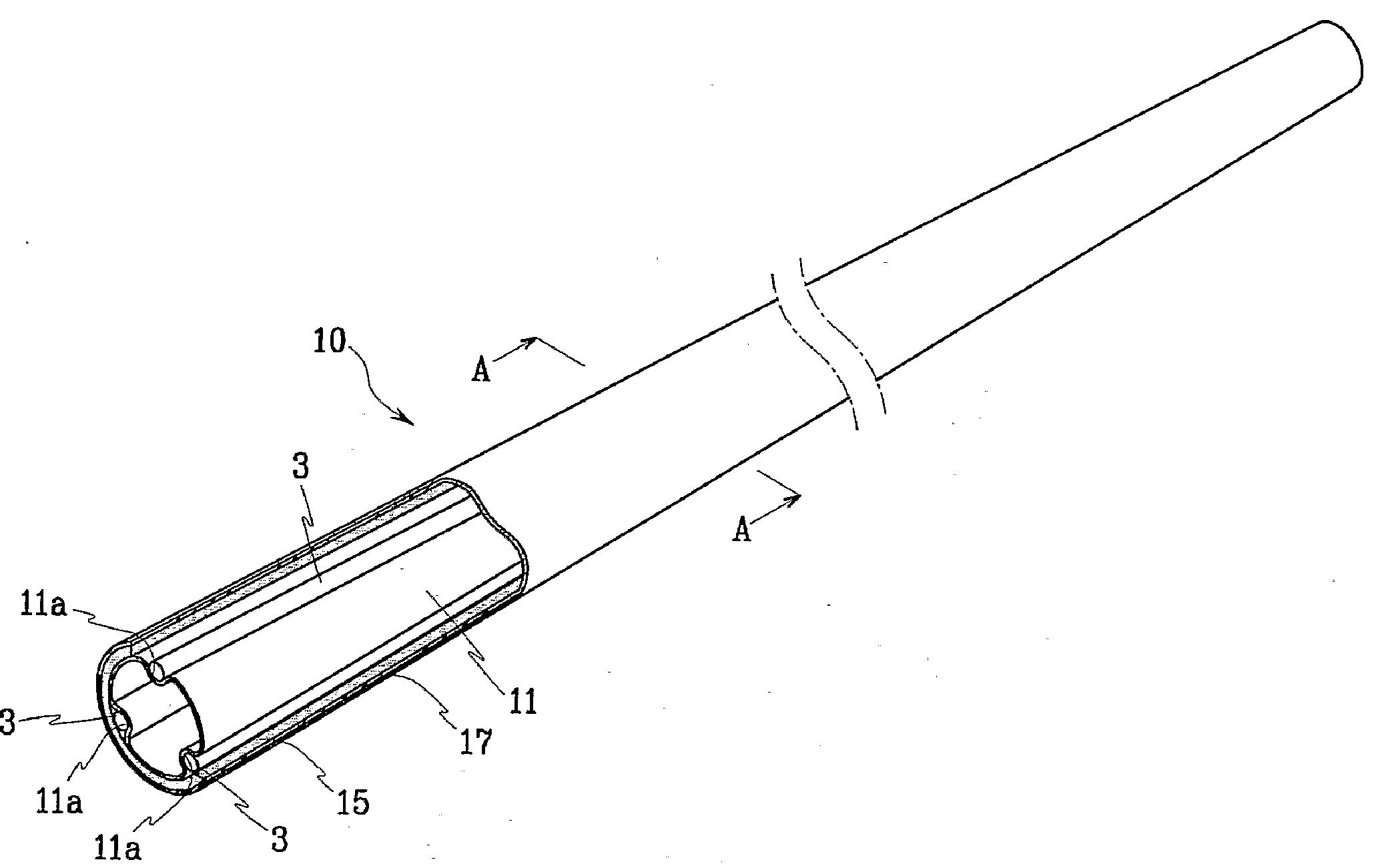

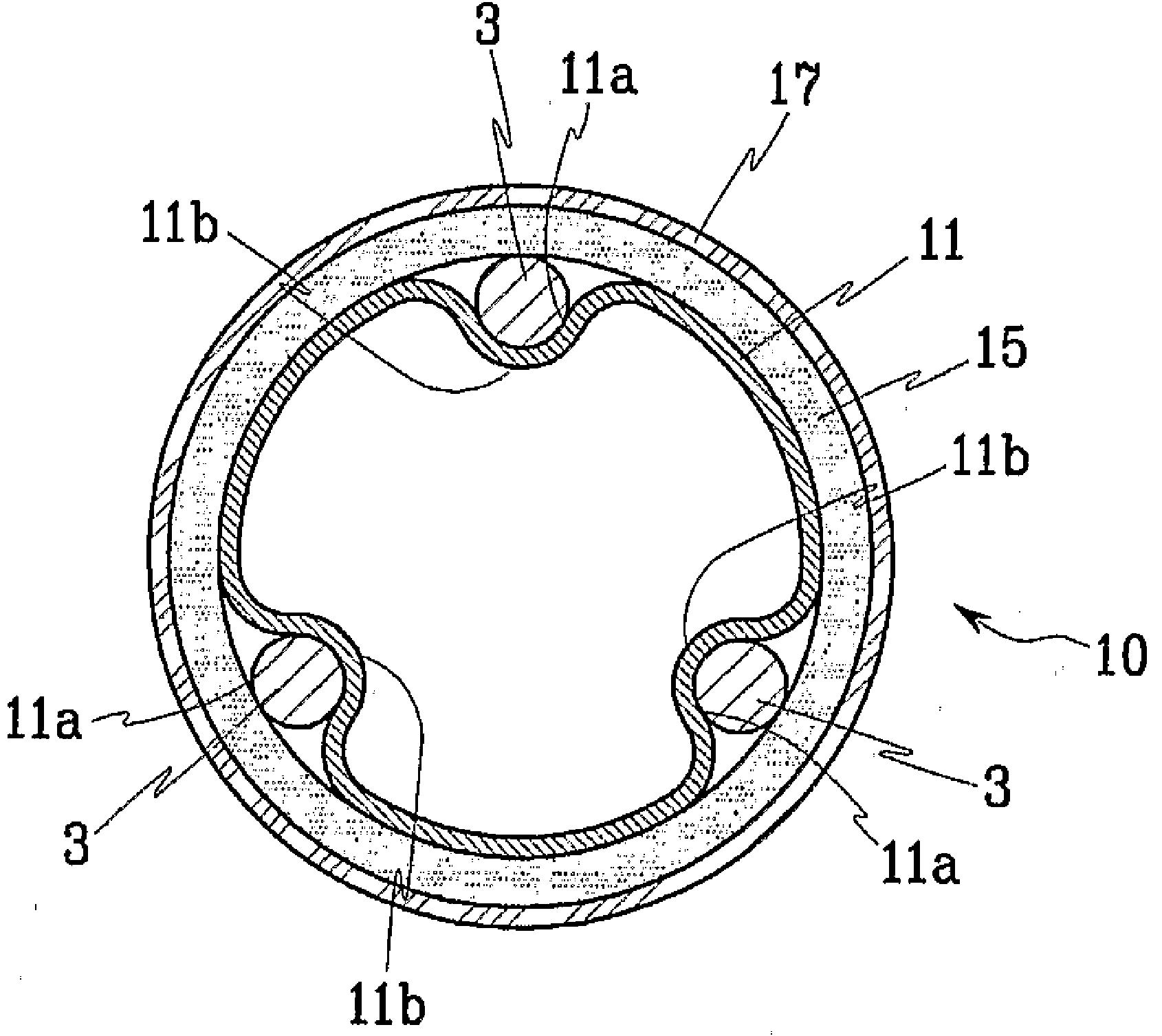

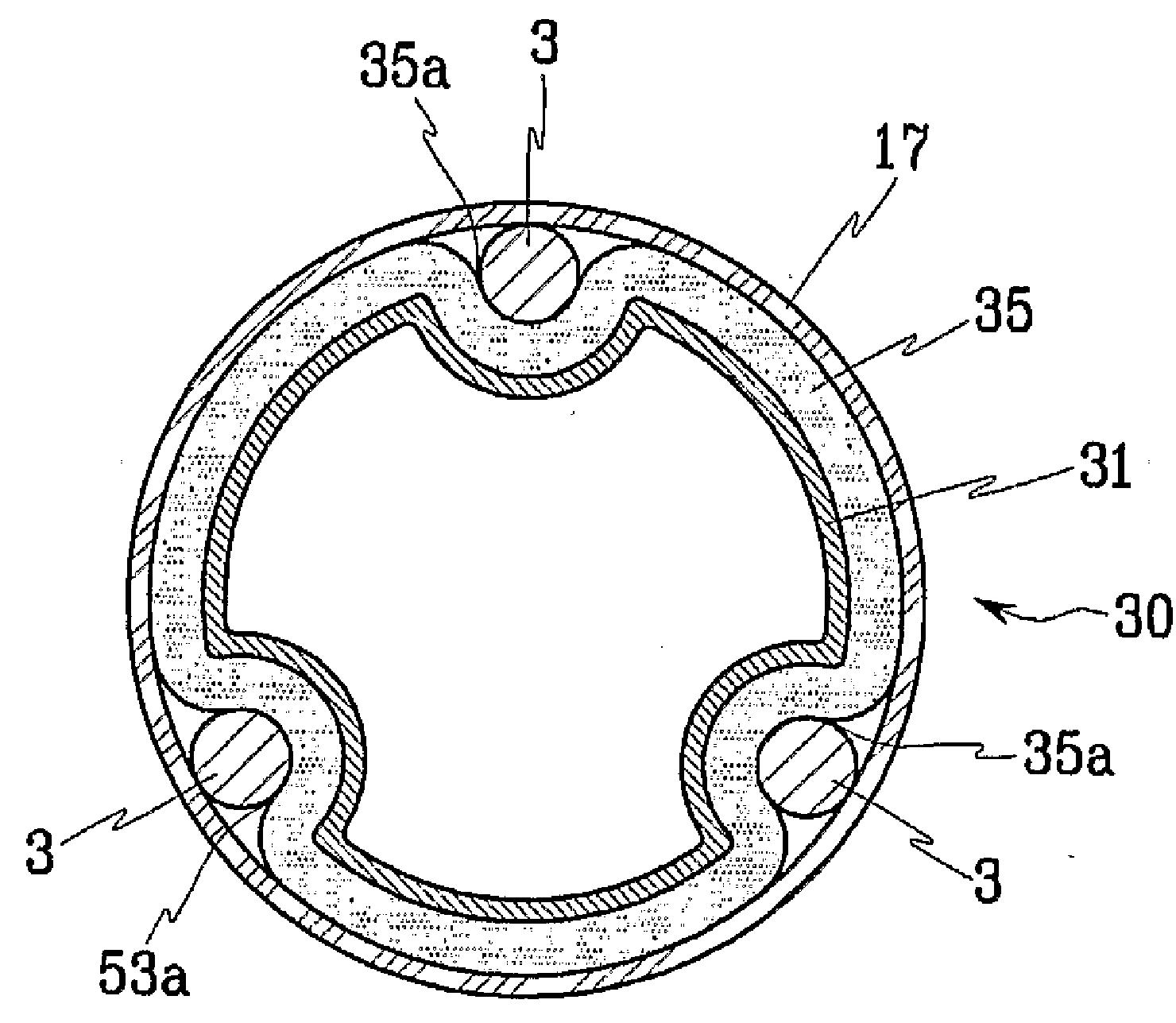

A precise impact and increased ball drive distance may be achieved due to an increase of elastic force and restoring force of a golf club shaft, when the golf club shaft includes: a first shell portion interiorly disposed in the golf club shaft; at least one elastic member disposed in a length direction on an exterior circumference of the first shell portion; and a second shell portion including carbon and enclosing the first shell portion and the at least one member.

Check out these figures:

Good stuff!

David Dawsey – Monitoring Golf Shaft Patents

PS – check out other golf shaft patent posts here