Forget About Dual Durometer Grips; How About Variable Durometer Grips!

An interesting golf grip patent recently issued. The patent is USPN 7510483 titled “Golf Club Grip,” and describes the invention as:

A pre-molded or moldable shaft grip includes a pre-configured or moldable section disposed within a substantially circular outer grip layer. A pre-configured or moldable section substantially conforms to a player’s grip, facilitating consistent finger placement. The pre-configured section may comprise the shaft, a separate section, or multiple sections of varying durometer. The moldable section may include a layer of moldable material, or a cavity disposed between the outer grip layer and the shaft containing a moldable substance. Overall grip durometer can be adjusted by varying the pressure within the cavity.

The patent goes on to explain:

A good grip is desirable when wielding any hand-held object. A firm and comfortable grip is important when using many hand-held tools equipped with a handle or shaft, such as hammers and axes. Moreover, many sports require a player to grip a handle or shaft on a piece of sporting equipment, e.g. tennis, cycling, hockey, golf, etc. Golfers for example strive for consistency, and a comfortable, firm grip with proper finger placement is one of the keys to a consistent golf game. Nevertheless, the typical club grip used by many golfers does not promote a comfortable, firm grip or proper finger placement.

The typical golf club grip is a single-layer molded rubber grip that has a pre-determined thickness and durometer. The durometer or hardness of the club grip is important because a player’s grip on the club will not feel secure if the grip is too hard or too soft. The right club grip “feel” varies widely among golfers. Most club grips, however, are only available in a few select levels of feel, such as soft, medium, or hard.

One way to improve club grip feel is to construct grips from multiple layers of material having different durometers. For example, Royal Precision’s Multi-Density Grip employs a low durometer color compound layer over a hard black inner core layer. Royal Precision advertises that the soft outer layer provides a custom grip “feel,” while the harder inner layer maintains stability by reducing torque and twisting at impact.

A similar design is used in existing cycle grips. One example of such grips are the ZyGo cycle grips made by A’ME. ZyGo grips have an inner-skeleton molded out of a hard rubber compound surrounded by a softer, tackier outer layer. A’ME advertises that the hard inner layer prevents torque between the handle bar and the rider’s hands, while the softer outer layer provides increased grip feel.

Grips with multiple layers, similar to standard single-layer grips, are typically available only available in a few select layer durometers. Thus, existing multiple-layer grips are similarly limited in their level of club grip feel. In addition, multiple layer grips do not address the problem of proper finger placement. Without a physical guide on the club grip, it is often difficult for beginning and intermediate players to locate the proper hand placement on the club grip. Thus, many players vary the placement of their hands and fingers on the club from shot to shot. This is a major contributor to a golfer’s lack of consistency on the golf course.

Most club grips lack any physical contours that could assist the golfer with proper and consistent finger placement when gripping the club. This is because the typical club grip is manufactured to comply with the rules of the United States Golf Association (“USGA”), which call for a club grip that is circular in cross section with no bulges or concavity. Nevertheless, there have been several attempts to improve the consistency in golf grip hand and finger placement through the addition of physical bulges or concavity in a golf grip.

For instance, U.S. Pat. Nos. 5,427,376 (“‘376”), 5,480,146 (“‘146”), and 6,540,621 (“‘621”) describe grips that are pre-shaped or pre-molded for a typical golfer’s fingers. Indentations formed or molded onto the outer surface of the club grip guide the player’s fingers and hands to the same location each time they grab the club. Yet, to accommodate the indentations and the bulges that indicate finger and hand placement, these grips are generally quite large and bulky. Another problem associated with the formed or molded indentations in these grips is that the bulges and concavities are obvious to other players, which can be a source of embarrassment for the player. Of course, these club grips also violate the USGA rules.Furthermore, because the grips disclosed by ‘376, ‘146, and ‘621 references are molded or formed to accommodate the hands and fingers of a typical golfer, the grips are not tailored to the physical and style characteristics of the individual player. Thus, these grips are unable to accommodate the differences in golfers’ hand sizes, finger lengths, grip styles (e.g., the overlapping grip, the 10-finger grip, the interlocking grip, etc.), or a combination thereof.

There have been attempts to offer a custom-mold club grip that improves the consistency of club grip finger placement to accommodate the unique physical characteristics of a player’s hands. One such attempt by a company called Fit Grip requires that a player grip a pre-heated material forming the club grip for a period of approximately 30 seconds, during which time indents are formed in the soft grip material at precisely the points where the hands and fingers contact the grip. After the grip has cooled, the impression remains permanently molded in the club. The club grip is capable of being molded additional times if necessary.

Although the molding of the club grip produces contours custom-fitted to each golfer’s hands, the resulting grip is still relatively large, obvious, and fails to conform to the USGA rules. An additional drawback is that the molded club grip must be fitted by a trained professional. Many avid golfers enjoy the work required to re-grip their clubs. By performing the re-grip themselves, golfers get a more intimate feel for their golf equipment and a greater sense of confidence when the equipment is used on the course.

It is an object of the present grips to provide an adjustable level of overall grip durometer, or “feel,” in a single grip. It is another object of the present grips to instill confidence in the player by increasing the surface area of the grip in contact with the player’s hands. It is yet another object of the present grips to provide a physical guide to assist in consistent and proper finger placement on a grip that is outwardly circular in cross section with no obvious bulges or concavity. It is an additional object of the present grips to provide a grip that may be custom-fitted by the player. Individual embodiments of the present grips may address some or all of these objectives.

These and other desirable characteristics of the present grips will become apparent in view of the present specification, including the claims and drawings. Although certain golf club grip examples are described in detail, the scope of this specification is not meant to limit its claims to only those examples shown. As such, those skilled in the art will appreciate that the conception, upon which this disclosure is based, may readily be utilized as a basis for the designing of other structures and methods for carrying out the several purposes of the present grips. It is important, therefore, that the claims be regarded as including such equivalent constructions insofar as they do not depart from the s

pirit and scope of the present grips.BRIEF SUMMARY OF THE INVENTION

The present grips are directed to an improved gripping apparatus and method of use, including an improved golf club grip.

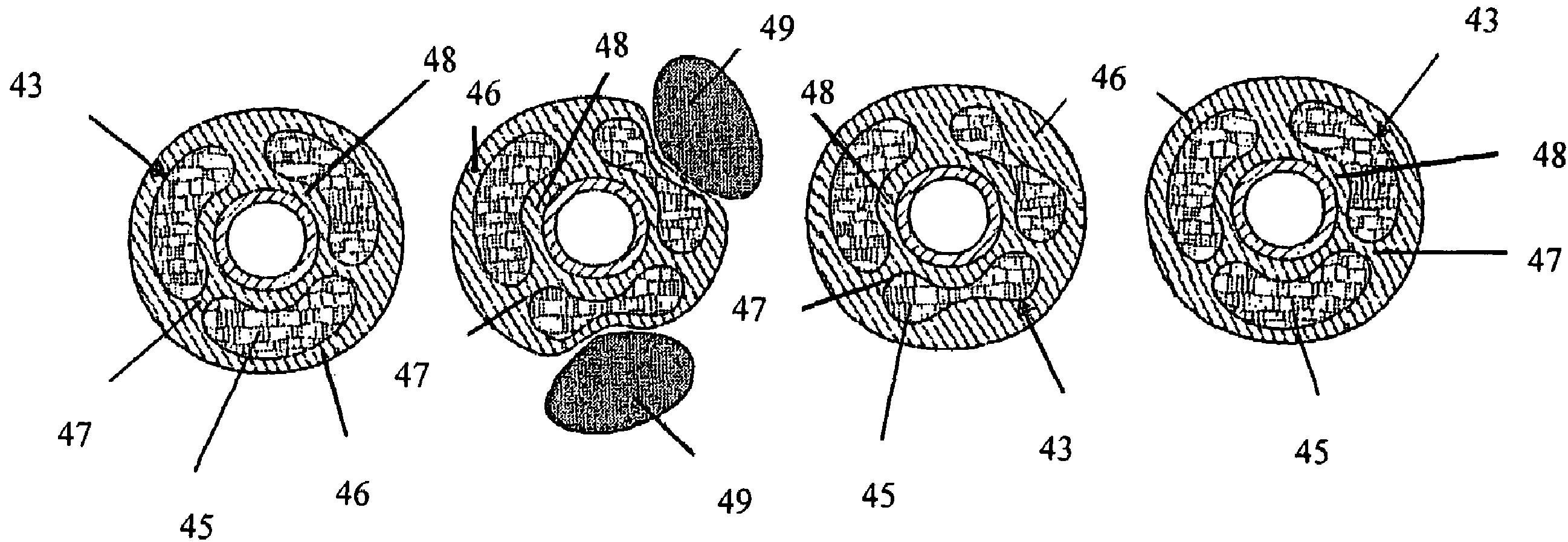

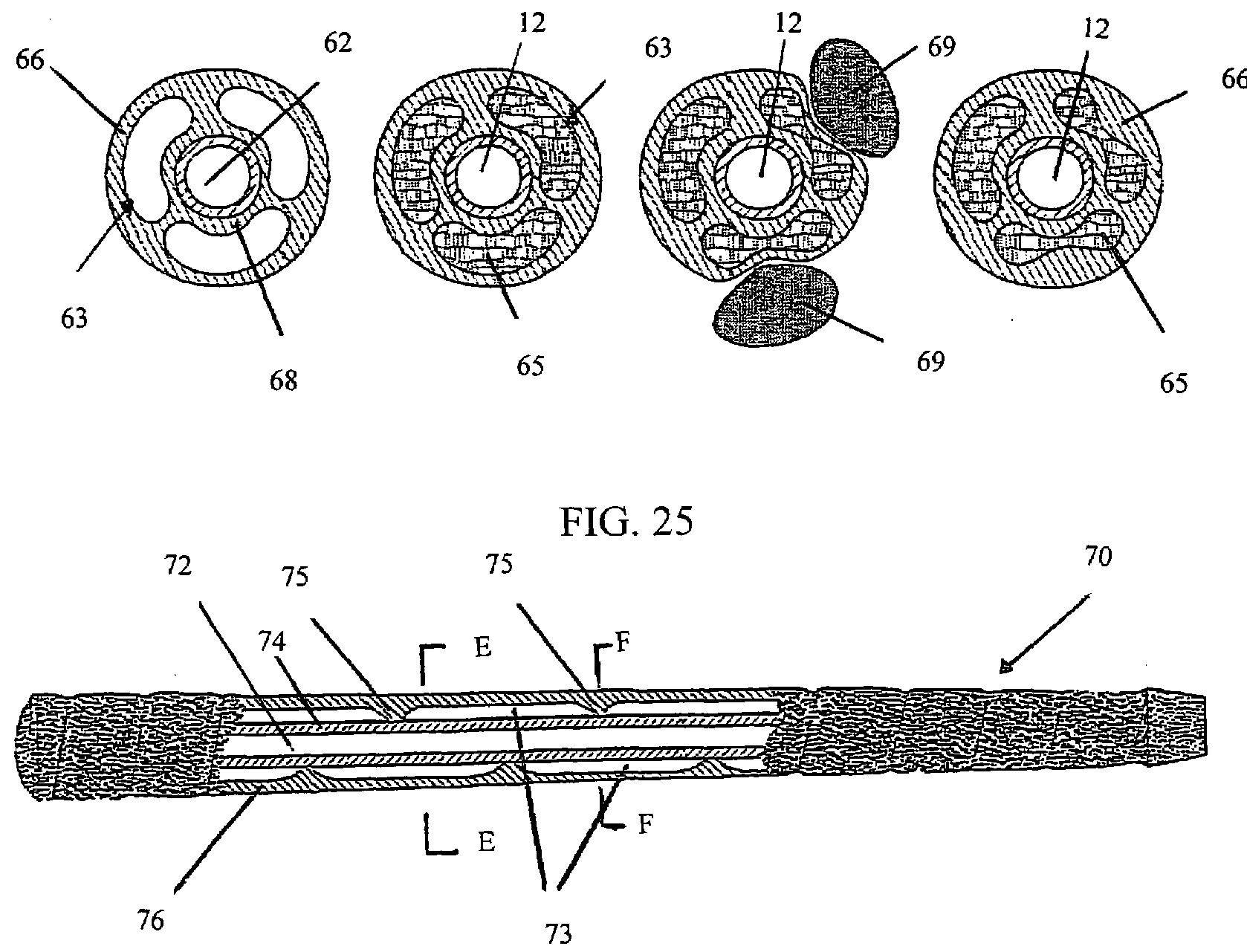

A preferred embodiment is, for example, a golf club grip that comprises an outer layer disposed around an inner layer. The inner layer has a higher durometer than the outer layer, which improves grip feel. The inner layer is also molded or moldable to substantially conform to the player’s grip, thereby facilitating consistent finger placement. The outer layer maintains a substantially circular cross section when not gripped. Alternatively, the inner layer may be omitted and the shaft itself can be molded to substantially conform to a player’s grip. In addition, a compression layer may be employed in addition to the outer layer to compress the outer layer to ensure that the outer layer maintains a circular cross section over the molded inner layer.

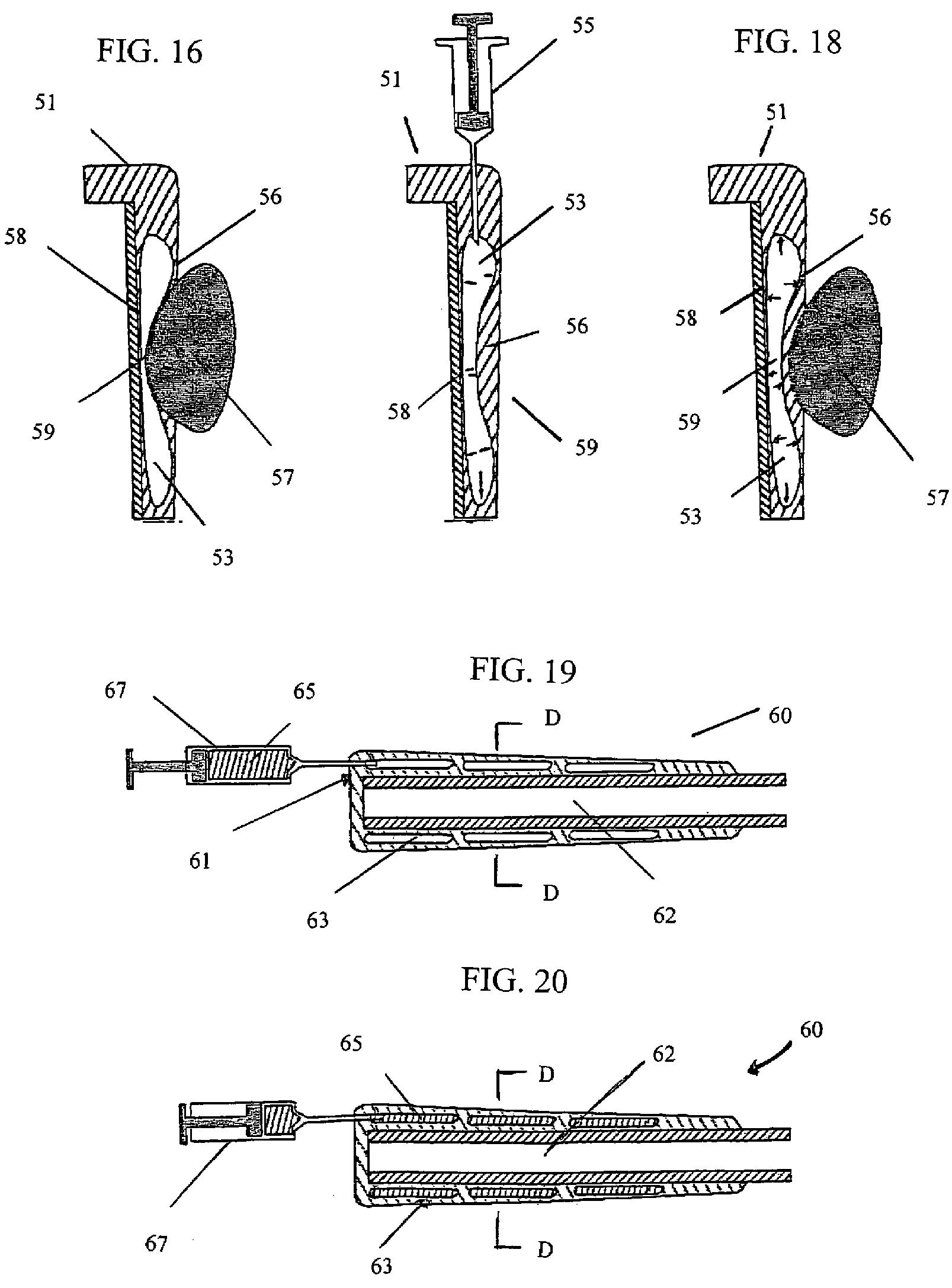

The preferred embodiment also may comprise a cavity disposed between an outer layer and an inner layer disposed around a shaft, or the shaft itself. The cavity may be expandable, and it may comprise a single space, or multiple subchambers. The subchambers may or may not be open to one another. The cavity may receive various substances, such as hardening agents, foam, or viscous liquids, to promote long or short-term conformity of the grip to a player’s hands. Air or other gases may also be added or removed from the cavity to alter overall grip durometer, or feel. A valve may be provided for access to the cavity.

The preferred embodiment also may comprise an apparatus comprising a first material having a first durometer, and a second material having a second durometer. The first durometer is higher than the second durometer. The second material is disposed around the first material and positioned to substantially correspond to the player’s finger placement, while the first material is positioned to correspond to areas of the grip that are not in contact with the player’s fingers. When gripped, this arrangement guides the player’s hands and fingers to the low durometer areas of the grip, which when gripped provide, in effect, concave impressions in the grip. When the grip is released, these low durometer areas return to their normal shape, giving the grip a substantially circular cross-section.Alternatively, the durometer of the first material may be lower than the durometer of the second material. When gripped, this arrangement guides the player’s hands and fingers to the areas of the grip where the low durometer inner material is the thickest.

The preferred embodiment may be manufactured as a wrap and wound around the club shaft. This wrappable grip may contain cavities, which may in turn contain other substances or materials to enhance the players grip on the club.

Perhaps “grip fitting” will become as common as club fitting and ball fitting. I wouldn’t mind being able to adjust the way that my grips feel. It would be interesting to know if these grip designs were ever determined to be USGA conforming.

Dave Dawsey – Keeping an Eye on Golf Grip Patents

PS – check out other golf grip patent related posts here