Do Your Shafts Have Enough Fullerene? Perhaps Insulting Senior Golfers Is a Good IP Strategy

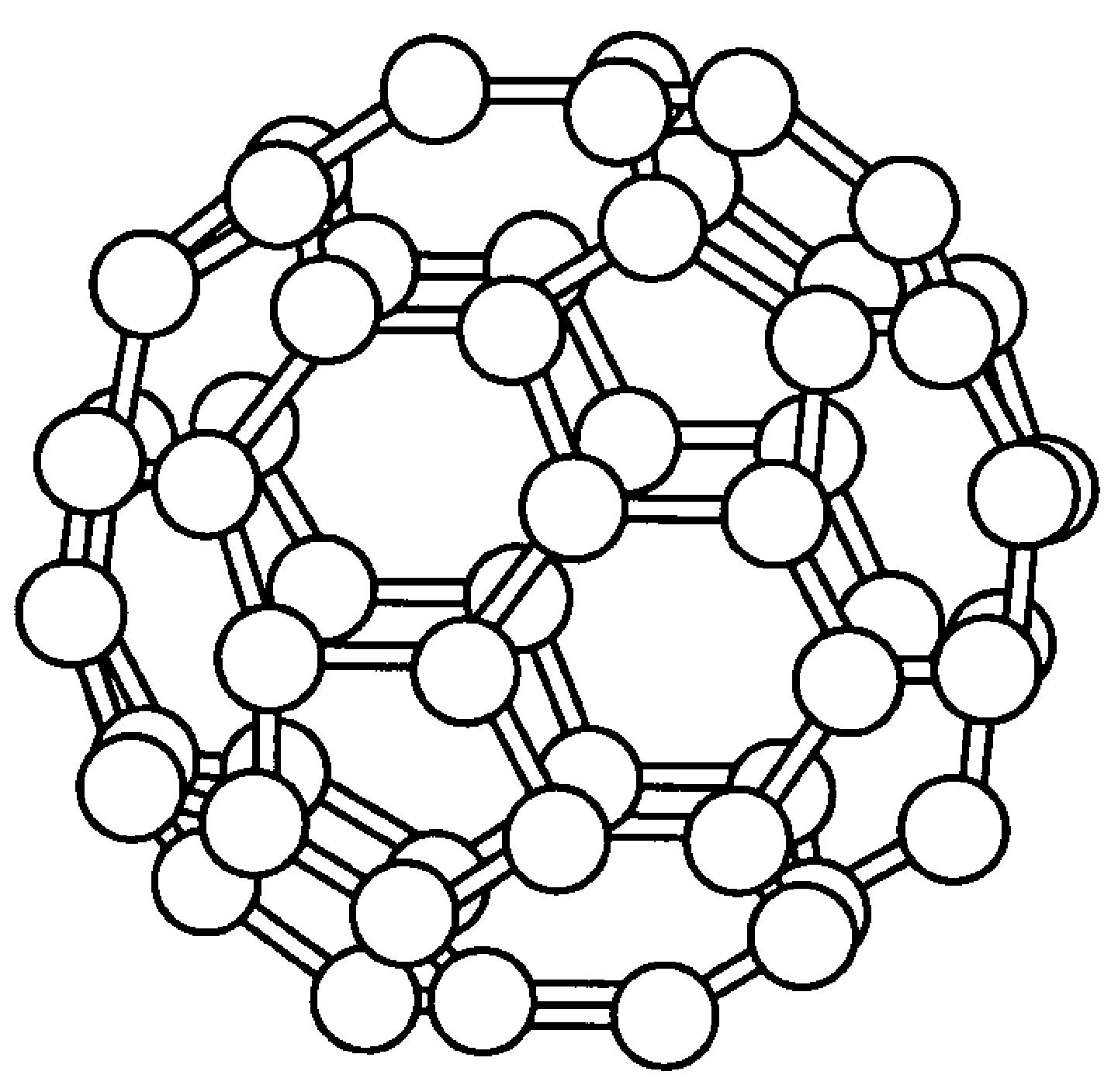

Can you identify this molecular structure?

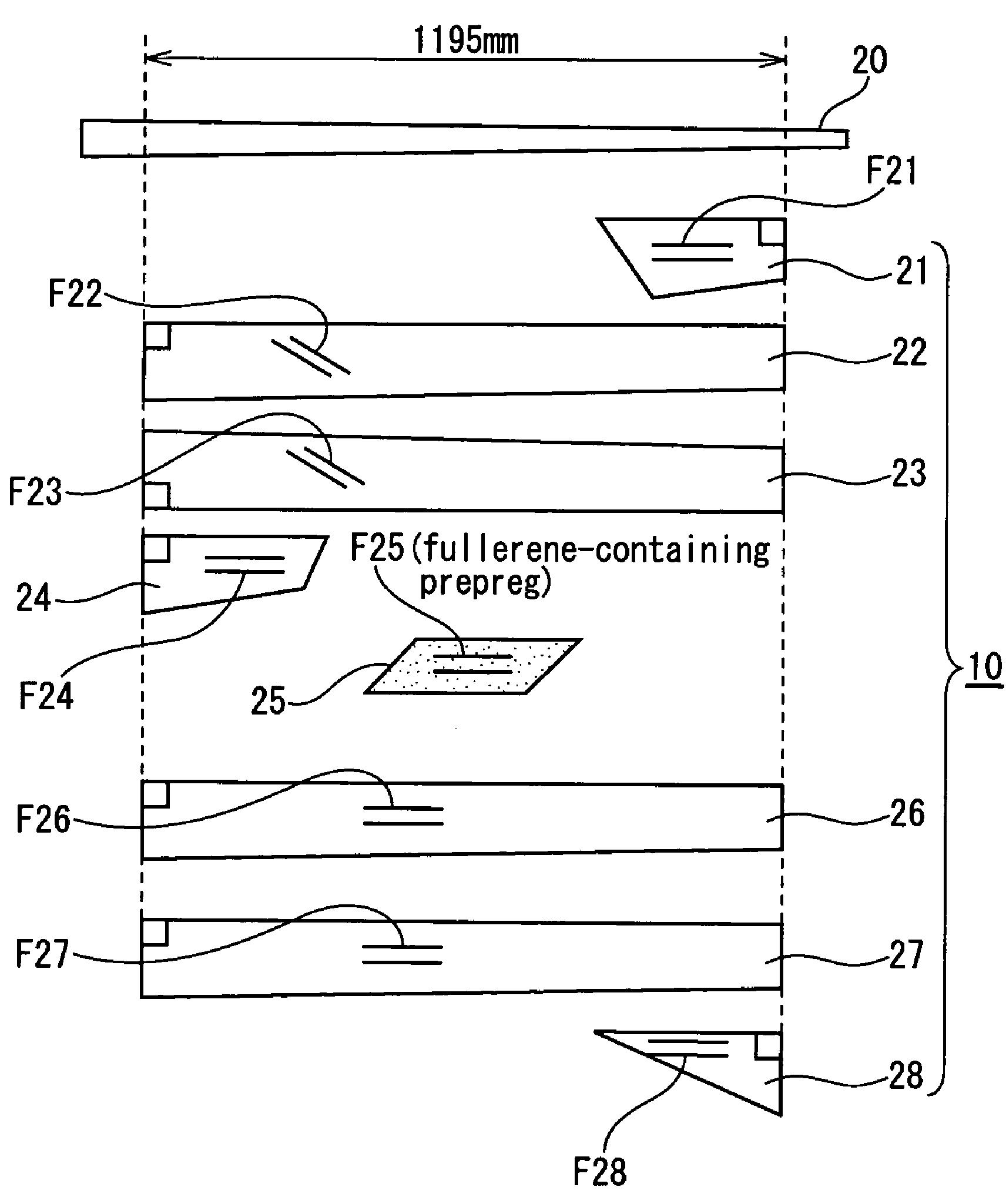

Luckily, the golf shaft designers at SRI Sports know the molecular structure of fullerene. Yesterday, SRI was granted an interesting golf shaft patent; namely, USPN 7517288 titled “Golf Club Shaft.” The patent describes the invention as:

A golf club shaft composed of a laminate of prepregs each containing a matrix resin and reinforcing fibers impregnated with the matrix resin. The matrix resin of at least one of the prepregs contains a fullerene or/and a fullerene compound. The content of the fullerene or/and the fullerene compound contained in the prepreg is set to not less than 0.002 wt % nor more than 1 wt % of an entire weight of the prepreg. The length of the prepreg containing the fullerene or/and the fullerene compound is set to not less than 2% nor more than 90% of the full length of the golf club shaft.

The patent goes on to explain the need for this new shaft design (and insult senior golfers at the same time):

In recent years, to allow golfers to hit golf balls at high speeds and stably in flight distances, the present tendency is to make a weight concentrate in a golf club head and make the golf club shaft as lightweight as possible. Therefore as the material of the golf club shaft, the fiber reinforced resin such as a carbon prepreg that is lightweight and has a high specific strength and specific rigidity is mainly used.

Owing to a low birth rate, there is a tendency for senior golfers to increase in the future. Thus there is a growing demand for the development of a golf club suitable for senior golfers. Because seniors are powerless, the golf club for them is demanded to be lightweight and have a high head speed so that flight distances of golf balls are constant. To increase the head speed, it is necessary to make the shaft soft and flexible. To this end, methods of decreasing the number of fiber layers of the shaft made of the fiber reinforced resin, decreasing the modulus of elasticity of fibers, and differentiating fiber angles from each other are conventionally used. But shafts manufactured by using these methods have a low strength. Thus it is difficult to manufacture a shaft having a light weight, a high flexibility, and a high strength.

To overcome the above-described problem, there are proposed golf club shafts as disclosed in Japanese Patent Application Laid-Open Nos. 2004-298357 (patent document 1) and 2004-188191 (patent document 2). In these patent documents, at least one part of the fiber reinforced resin layers composing the shaft contains the carbon nano-tube. According to the description made in the specification of the patent documents, the shaft is allowed to have a restrained bending rigidity, a light weight, and a high strength.

The carbon nano-tube is a faultless single layer tubular material formed by cylindrically rounding a flat hexagonal net of graphite or a multi-layer tubular material composed of hexagonal nets of graphite layered one upon another in a telescopic system. The carbon nano-tube is a superfine carbon fiber having a diameter in the range of 1 nm to 100 nm and has mechanical properties superior to conventional carbon fiber in its torsional strength and bending strength.

Because the carbon nano-tubes are cylindrical, they have a low fluidity and are liable to aggregate with one another. To make the sizes (longitudinal length) of the carbon nano-tubes equal to each other, it is necessary to precisely control arc discharge to be performed between carbon electrodes in manufacturing the carbon nano-tubes. It is difficult to manufacture the carbon nano-tubes having a uniform size. Therefore variations are liable to occur in the strength distribution of the fiber reinforced resin containing the carbon nano-tubes.

SUMMARY OF THE INVENTION

The present invention has been made in view of the above-described problems. Therefore it is an object of the present invention to provide a golf club shaft that is lightweight and has a proper degree of flexibility and strength.

To achieve the object, the present invention provides a golf club shaft composed of a laminate of prepregs each containing a matrix resin and reinforcing fibers impregnated with the matrix resin. The matrix resin of at least one of the prepregs contains a fullerene or/and a fullerene compound.

The fullerene is a carbon allotrope having a three-dimensional hollow spherical structure closed with covalent bonds of sp2 carbon atoms. As the molecular structure of the fullerene, carbon atoms construct five-membered rings and six-membered rings, thus constructing a polyhedron. Representative fullerene is soccer ball-shaped C60 composed of 60 carbon atoms constructing 12 five-membered rings and 20 six-membered rings. The C60 is inexpensive, can be mass-produced, and is physically stable. In addition to C60, it is possible to use C70, C74, C76, C78, C80, C84, C82, and C90. These fullerenes can be used singly or in combination.

As the fullerene compound, it is possible to use halogen-introduced C60Fn (n=30 through 52), C60C124, C60Brn (n=6, 8, 24), hydroxyl group-introduced C60(OH)24, hydrogen-added C60H24, a fullerene compound composed of the fullerene and metal such as Na, K, Rb or Cs doped in the crystal of the fullerene.

By mixing the fullerene or/and the fullerene compound with the matrix resin of the prepreg composing the shaft, it is possible to restrain an increase of the weight of the shaft and the rigidity thereof and yet enhance the bending modulus of elasticity and strength thereof.

This is because the hollow spherical fullerene and fullerene compound absorb a breaking energy, and in addition the fullerene and the resin combine with each other to form a firm crosslinking structure. Further the spherical fullerene is higher than the above-described cylindrical carbon nano-tube in its fluidity and dispersibility. Thus the fiber reinforced resin containing the hollow spherical fullerene has little variations in its strength.

As the fullerene to be used in the present invention, C60, C70, and C80 soluble in an organic solvent can be preferably used. To uniformly disperse the fullerene in the matrix resin, it is preferable to dissolve and disperse the fullerene and a monomer of the matrix resin in the organic solvent and evaporate the organic solvent by an evaporator.

After the fullerene is added to the matrix resin, it is preferable to knead them with a kneader, a three-roll or a biaxial extruder to disperse the fullerene in the matrix resin by utilizing a shear force.

To enhance the dispersibility of the fullerene, it is preferable to chemically treat the surface thereof with a surface-active agent such as polyoxyethylene lauryl ether.

It is possible to use the fullerene compound formed by bonding the fullerene such as C60, C70, and C80 with a functional group such as a hydroxyl group or metal atoms. In this case, it is possible to chemically bond the resin of the fiber reinforced resin or the surface of the reinforcing fiber with the functional group of the fullerene. Such a fullerene compound has improved affinity for the resin of the fiber reinforced resin and is hence capable of mixing with the resin to a high extent.

As the size of the fullerene or/and the fullerene compound to be added to the matrix resin, it is favorable that the average diameter of molecules thereof are not less than 0.6 nm nor more than 3.5 nm. The fullerene having an average diameter of le

ss than 0.6 nm is theoretically present but it is very difficult to collect or produce it. Further the fullerene having an average diameter of less than 0.6 nm has a small area of contact between it and the matrix resin of the fiber reinforced resin. Consequently a weak bonding occurs between the fullerene and the matrix resin. Thereby the shaft has a low strength increase rate. When the average diameter of molecules of the fullerene or/and the fullerene compound are more than 3.5 nm, the molecules of the fullerene are very large. Thereby the fullerene has a low degree of dispersibility in the matrix resin of the fiber reinforced resin. Consequently a weak bonding occurs between the matrix resin and the fullerene and the fullerene compound. Thereby the shaft has a weak strength. The lower limit of the average diameter of the molecules of the fullerene or/and the fullerene compound is set to more favorably 0.7 nm and most favorably 0.75 nm. The upper limit of the average diameter of the molecules thereof is favorably 3.2 nm and most favorably 2.8 nm.It is favorable that the length of the prepreg containing the fullerene or/and the fullerene compound (hereinafter often referred to as fullerene-containing prepreg) is set to not less than 2% nor more than 90% of the full length of the shaft. If the length of the fullerene-containing prepreg is less than 2%, the shaft has a small fullerene-containing region. Thus the length of the fullerene-containing prepreg is insufficient for improving the strength of the shaft. The length of the fullerene-containing prepreg is set to more favorably not less than 4% and most favorably not less than 6%. To improve the strength of the shaft, it is effective to widen the region in which the fullerene-containing prepreg is disposed. In this case, the shaft is expensive because the fullerene is very expensive. Therefore the length of the fullerene-containing prepreg is not more than 90% and more favorably not more than 80%. The fullerene-containing prepreg may be disposed over the full length of the shaft.

The full length of the golf club shaft is favorably not less than 800 mm nor more than 1270 mm. If the full length of the golf club shaft is less than 800 mm, the shaft is short and has a short flexing width. Thereby the shaft is incapable of displaying the effect to be brought about by the fullerene-containing prepreg. On the other hand, if the full length of the golf club shaft is more than 1270 mm, the shaft is difficult to swing and hence unsuitable for powerless seniors. In addition, it is necessary to use a large amount of the fullerene for the long shaft to allow the shaft to display the effect to be brought about by the fullerene-containing prepreg. Thereby the cost of manufacturing the shaft is high. The lower limit of the full length of the golf club shaft is set to more favorably 820 mm and most favorably 840 mm. The upper limit of the full length thereof is set to more favorably 1245 mm and most favorably 1219 mm.

When the fullerene-containing prepreg is disposed in a part of the shaft, it may be disposed in a region at the side of the head thereof, a region at the side of the grip thereof, and a central region thereof.

A concentrated stress is applied to the region at the side of the head of the shaft at a ball-hitting time. Therefore it is possible to effectively enhance the strength of the shaft when the fullerene-containing prepreg is disposed in the region at the side of the head of the shaft. In addition, because the fullerene-containing prepreg is excellent in its bending modulus of elasticity and bending strength, the fullerene-containing prepreg disposed in the region is capable of relieving a very high load applied to the region at the ball-hitting time, thereby preventing breakage of the shaft.

When the fullerene-containing prepreg is disposed at the central region of the shaft, a bending load is applied to the central region of the shaft owing to flexing of the shaft at the ball-hitting time. Therefore it is preferable to dispose the fullerene-containing prepreg excellent in its bending modulus of elasticity and bending strength in the central region of the shaft. When the fullerene-containing prepreg is disposed in the central region of the shaft, it is preferable to extend a part of the fullerene-containing prepreg disposed at the head side.

When the fullerene-containing prepreg is disposed in the region at the side of the grip of the shaft, a stress is relieved by the fullerene-containing prepreg. Thus the fullerene-containing prepreg relieves a shock at the ball-hitting time, thus giving a mild feeling to golfer’s hands.

It is preferable to dispose the fullerene-containing prepreg in the region at the side of the head of the shaft and the region at the side of the grip thereof.

It is preferable to dispose the fullerene-containing prepreg in an intermediate layer between an inner layer and an outer layer. It is particularly preferable to interpose the fullerene-containing prepreg between a bias layer whose fiber angle forms .+-.45.degree. to the axis of the shaft and a straight layer whose fiber angle forms 0.degree. to the axis thereof.

In a swing behavior, a force acting in a twist direction and a force acting in a bending direction are simultaneously applied to the shaft. By disposing the fullerene-containing prepreg between the bias layer and the straight layer having effects for the forces acting in the twist direction and the bending direction, the fullerene-containing prepreg relieves a shearing generated to a stress-generated direction when the layer between the bias layer and the straight layer twists, thereby preventing an interlaminar separation.

It is favorable that the content of the fullerene or/and the fullerene compound contained in each layer consisting of the fullerene-containing prepreg is set to not less than 0.002 wt % nor more than 1 wt % of the entire weight of the prepreg.

When the content of the fullerene or/and the fullerene compound (hereinafter referred to as fullerene content) is less than 0.002 wt %, the fullerene content is so small that the fullerene-containing prepreg is incapable of sufficiently displaying the effect of improving the strength of the shaft. On the other hand, when the fullerene content is more than 1 wt %, an aggregation action occurs and hence the fullerene or/and the fullerene compound have a low dispersibility in the matrix resin. Consequently the prepreg has a variation in the strength thereof and hence a low strength.

The lower limit of the fullerene content is set to favorably 0.005 wt %, more favorably 0.008 wt %, and most favorably 0.01 wt % of the entire weight of the prepreg. The upper limit of the fullerene content is set to favorably 0.8 wt % and more favorably 0.7 wt % of the entire weight of the prepreg.

As described above, according to the present invention, the prepreg composed of the matrix resin containing the fullerene or/and the fullerene compound having a high dispersibility is used for the shaft. Thereby it is possible to restrain an increase of the weight of the shaft and the bending rigidity thereof and yet effectively enhance the strength thereof without variations. Therefore the shaft of the present invention is lightweight and has a high flexibility and strength and is hence suitable for powerless players such as senior golfers.

Who knew fullerene was so handy! Talk about some brain power going into shaft design.

David Dawsey – Monitoring Golf Shaft Patents

PS – check out other golf shaft patent posts here